High temperature-resistant impact-resistant composite material housing, and molding method thereof

A technology of composite materials and molding methods, applied in other household appliances, household components, applications, etc., can solve the problems of increased overall weight, reduced sailing speed, restrictions, etc., to achieve the effect of improving overall strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

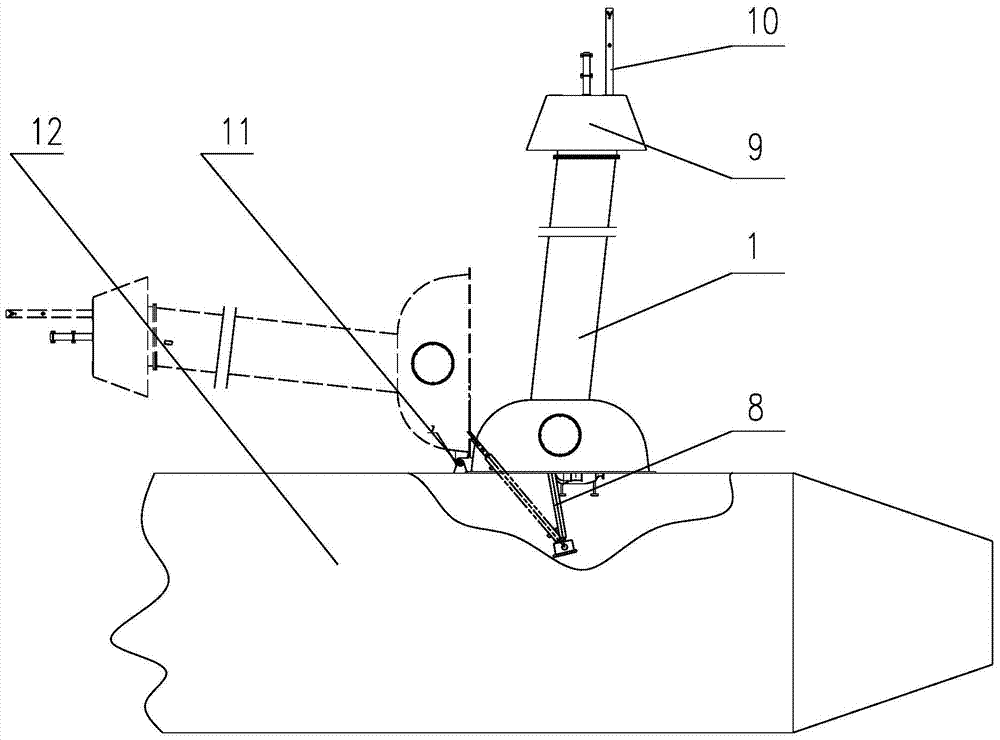

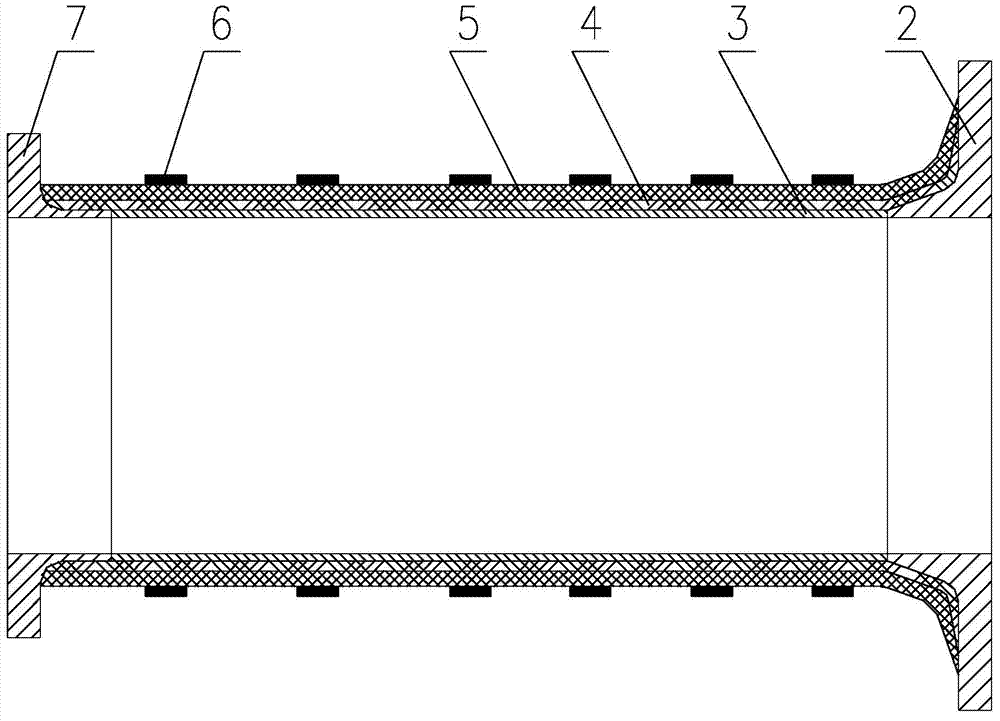

[0026] This embodiment provides a mast made of high temperature and impact resistant composite materials, figure 2 Shows where this mast would fit on the underwater vehicle. The mast is the channel for the internal power source of the underwater vehicle to discharge exhaust gas, and also serves as the installation platform for the communication antenna base. In the present embodiment, the total length of the mast is 5m and the diameter is 150mm. Most of the mast moves with the aircraft under the water surface during work. During the movement of the aircraft, it is required that the mast can still work normally under the condition of bearing a certain impact force and the internal 250°C airflow; at the same time, its weight should be minimized under the condition of satisfying the strength and rigidity of use.

[0027] In order to make the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com