Mechanical punching machine

A stamping machine and mechanical technology, applied in the direction of stamping machines, mechanical equipment, presses, etc., can solve the problems of high cost consumption, inability to apply pressure, and increase in the number of parts, and achieve the effect of reducing production costs and precise linear motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

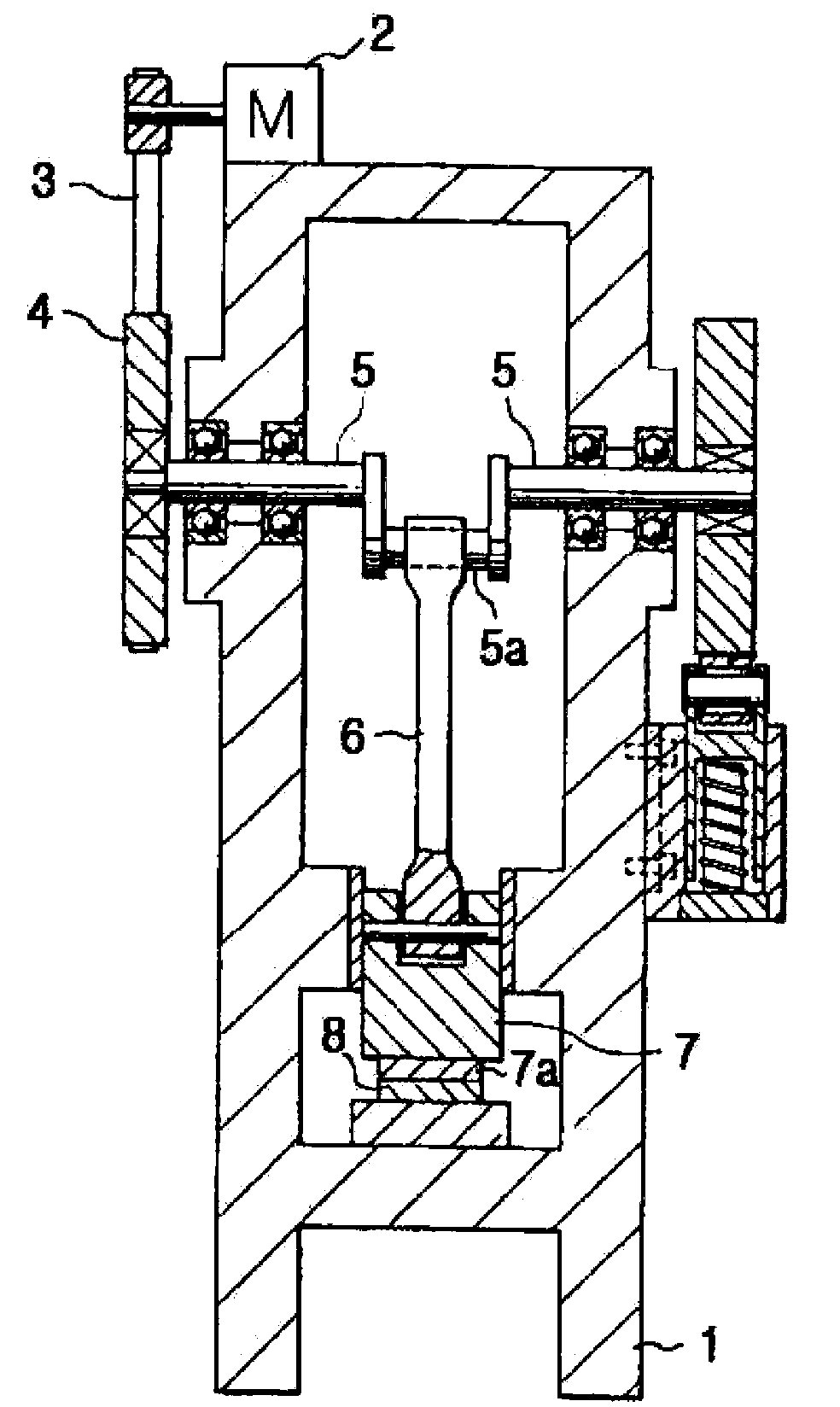

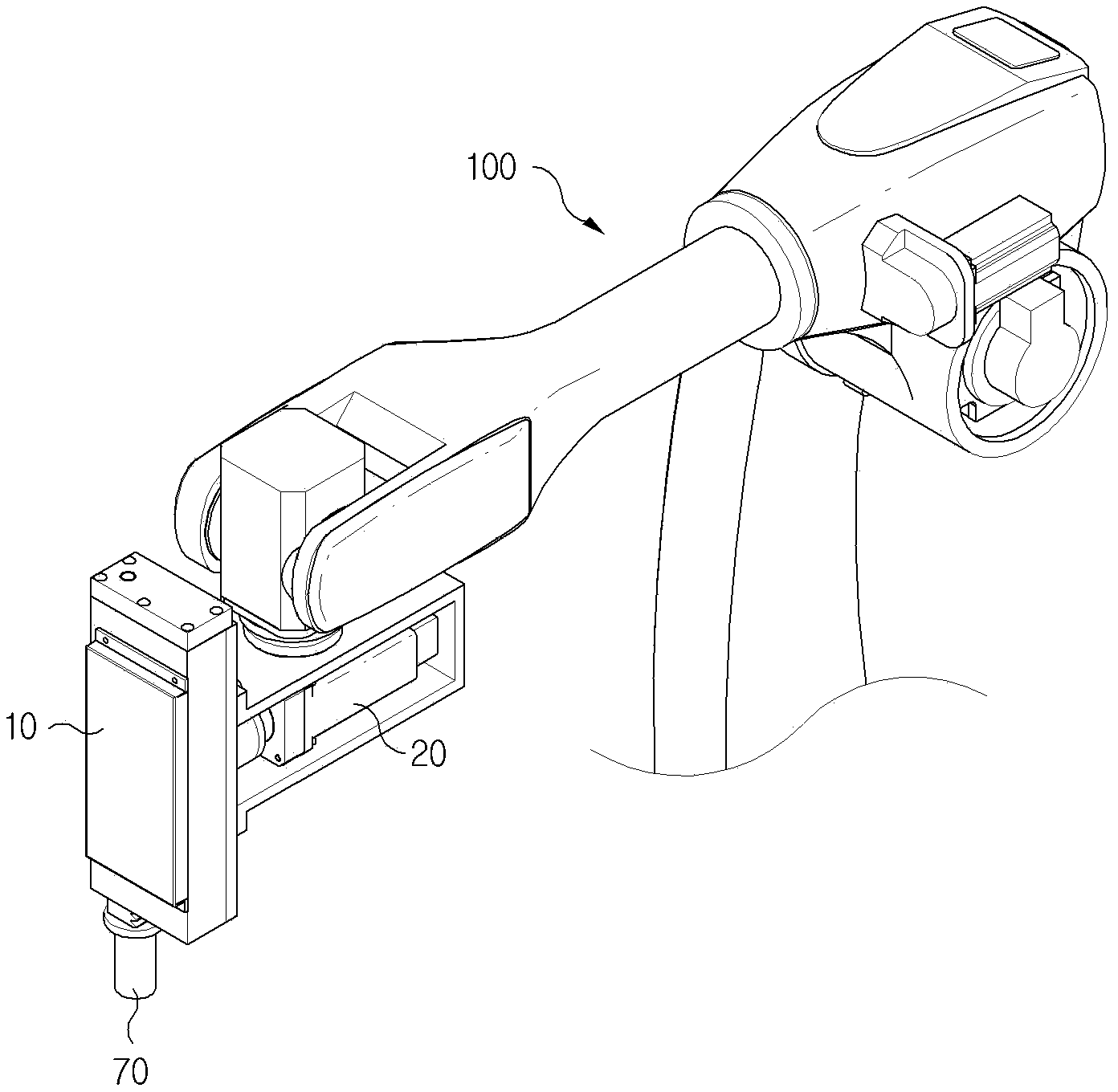

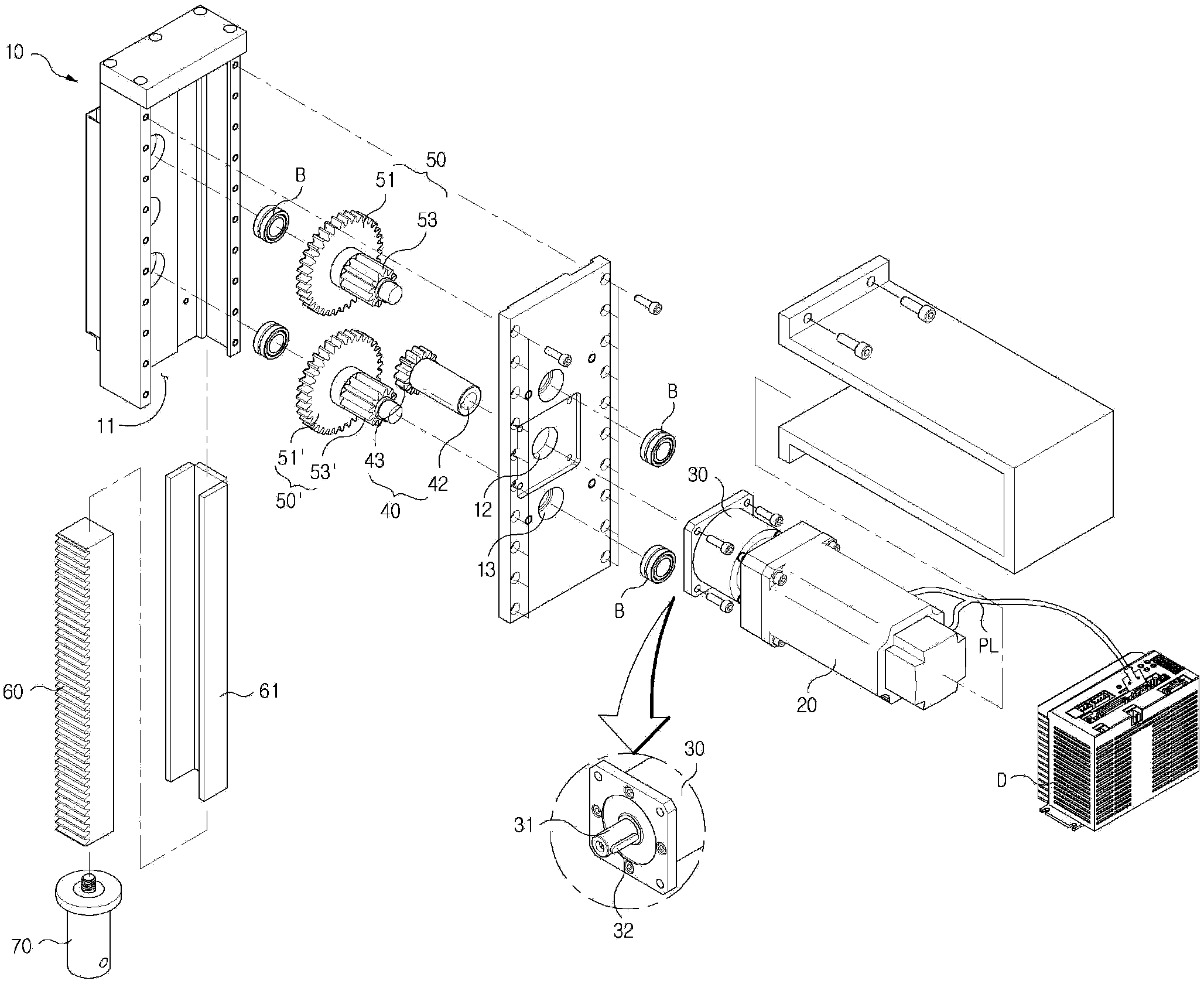

[0036] figure 2 is a schematic diagram of a mechanical punching machine according to the present invention; image 3 It is an exploded schematic view of the mechanical punching machine according to the first embodiment of the present invention; Figure 4a-Figure 4b for image 3 operating status diagram.

[0037] The invention provides a mechanical punching machine, which converts the rotary motion into a linear motion according to the transmission gear and the driving gear, and applies pressure to the object to be plastically deformed, so as to perform processing such as bending, shearing, and section shrinkage, or pressing Into the assembly of mechanical device parts.

[0038] The mechanical punching machine is composed of a hollow housing 10 with an opening 11 formed on one side and a through hole 12 formed on the side; a servo motor 20 disposed outside the housing 10; disposed between the servo motor 20 and the housing 10, The speed reducer 30 that decelerates the rota...

Embodiment 2

[0071] Figure 5 It is an exploded schematic view of the second embodiment of the mechanical punching machine according to the present invention; Figure 6a-Figure 6b for Figure 5 running status diagram; Figure 7 for Figure 5 Another state diagram of .

[0072] In the following description, the same symbols are used for the same structures as those of the first embodiment, and the description thereof is omitted.

[0073] The third gear 53, 53' of the power transmission gear part 50, 50' and the above-mentioned transmission gear 60 are also provided, arranged at predetermined intervals, and share the rotational power of the third gear 53, 53', and then transmit it to the above-mentioned transmission gear. A plurality of driving gears 80 of gear 60 .

[0074] In order to maximize the large-capacity torque transmission and the durability increase effect by the above-mentioned torque sharing, the above-mentioned transmission gear 60 further includes a transmission gear 60a...

Embodiment 3

[0083] Figure 8 It is a schematic diagram of the third embodiment of the mechanical punching machine according to the present invention; Figure 9 for Figure 8 Another state diagram for ; Figure 10 for Figure 9 Another state diagram for .

[0084] In the following description, the same symbols are used for the same structures as those of the first embodiment, and the description thereof is omitted.

[0085] The mechanical punching machine is composed of a hollow housing 10 with an opening 11 formed on one side and a through hole 12 formed on the side; a servo motor 20 disposed outside the housing 10; disposed between the servo motor 20 and the housing 10, The speed reducer 30 that decelerates the rotation speed of the above-mentioned servo motor 20; the power gear part 40 that is connected to the above-mentioned speed reducer 30 through the through hole 12 of the above-mentioned housing 10 to form a first gear 43; The transmission gear 60 of the gear 43; and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com