Carbonization-activation bilateral reaction furnace for producing active carbon by biomass

A technology for producing activated carbon and biomass, which is applied in the field of reactor for producing activated carbon, producing activated carbon from biomass, and carbonization and activation of straw crops, which can solve the problems of high energy consumption, large energy consumption, insufficient reflection reaction, etc. Improve the efficiency of reflection and simplify the effect of subsequent process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

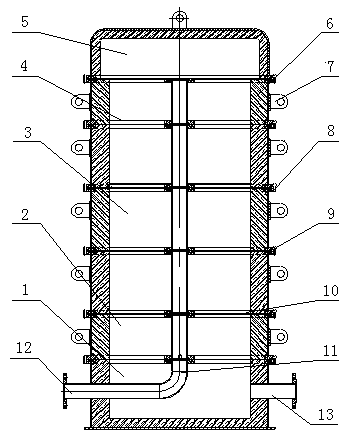

[0030] figure 1 It is a schematic diagram of the structure of the present invention.

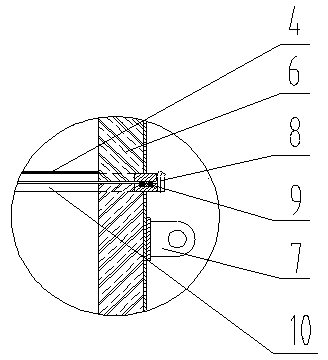

[0031] Such as figure 1 As shown, this embodiment provides a carbonization-activation two-way reaction furnace for producing activated carbon from biomass, including a reaction chamber 3, which also includes a gas delivery pipe I12, a gas delivery pipe II13, a delivery pipe group 11, a support frame 10 and a screen 4, The reaction chamber 3 is provided with a supporting frame 10 above and below, and a screen 4 is provided on the upper surface of the supporting frame 10, and a mesh is provided on the screen 4. The screen 4 is used as a bearing plate for biomass or activated carbon, and is fixed on the support frame 10. The support frame 10 is made of stainless steel 304 material. Each set of screens 4 is composed of the same 3 fan-shaped screens, which is convenient for installation and replacement, while ensuring The air flow is evenly distributed to make the reaction full and complete.

...

Embodiment 2

[0037] This embodiment focuses on the carbonization-activation two-way reaction furnace for producing activated carbon from biomass with a clean room.

[0038]In this embodiment, the uppermost reaction chamber 3 is provided with a clean room 2, and the lowermost reaction chamber 3 is provided with a clean room 2. After the reaction gas is carbonized and activated in the reaction chamber 3, it passes through the clean room 2. In the clean room 2, Equipped with activated carbon, activated carbon has the function of absorbing tar and dust, and purifying the reaction gas.

[0039] The present invention can also adopt other airway setting methods.

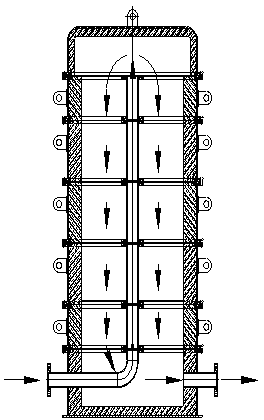

[0040] The gas delivery pipe I12 is connected to the lower end of the delivery tube set 11, and the upper end of the delivery tube set 11 communicates with the upper end of the material. The air delivery pipe II13 and the air delivery pipe I12 are arranged horizontally and symmetrically, and communicate with the lower end of the materi...

Embodiment 3

[0044] The present invention also provides a carbonization-activation method for producing activated carbon from biomass, comprising the following steps:

[0045] Ⅰ. Combustion stage: use the biogas produced in the biogas tank and the pyrolysis gas generated in the previous carbonization process to burn the biogas and pyrolysis gas to generate high-temperature flue gas;

[0046] Ⅱ. Heat exchange reaction stage: use the biogas produced in the biogas tank and the pyrolysis gas generated during the carbonization process to control the delivery volume, and fully exchange heat between the pyrolysis gas and the high-temperature flue gas generated in the combustion stage, so that the temperature of the pyrolysis gas reaches 700°C-800°C, it will be transported to the carbonization furnace to make the pyrolysis gas react with the biological straw to realize carbonization-activation;

[0047] Ⅲ. Cooling stage: use the biogas produced in the biogas tank and the pyrolysis gas generated du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com