Automatic deslagging and stirring methane tank

An automatic slag discharge and biogas digester technology, applied in the field of biogas digesters, can solve problems affecting the fermentation process, hindering the rise of biogas, and reducing biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

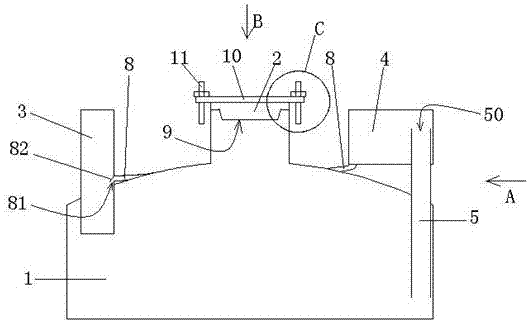

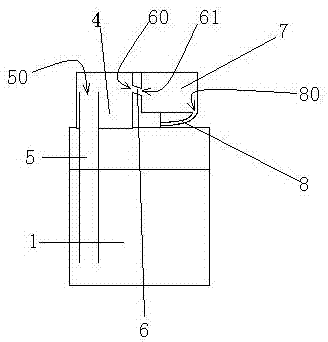

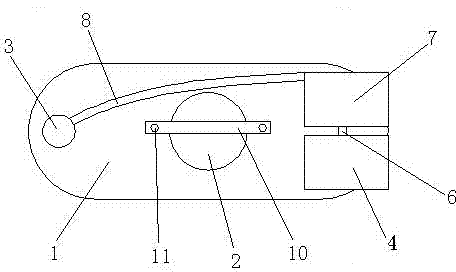

[0021] Such as figure 1 As shown, the present invention includes a fermentation tank 1 provided with a pool mouth, the pool mouth is sealed by a pool cover 2, a feed pipe 3 and a slag discharge chamber 4 are also provided at both ends of the fermentation tank, and a discharge pipe is provided at the bottom of the fermentation tank 1 5. The other end of the discharge pipe 5 is connected to the slag discharge chamber 4 , and the discharge port 50 of the discharge pipe 5 is higher than the bottom of the slag discharge chamber 4 .

[0022] The slagging chamber 4 is connected to the fermentation tank 1 by the principle of a connector, and when the raw materials in the fermentation tank 1 generate biogas, an air chamber is formed on the upper part of the fermentation tank 1 . With the increase of biogas, the pressure of the air chamber increases, and the raw material sediment in the fermentation tank 1 will be squeezed to the slag discharge chamber 4, so the extruded sediment can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com