A winding mechanism of a pinecone machine

A technology of loosening ball machine and coiling strip, applied in winding mechanism, textile and papermaking, fiber processing and other directions, can solve the problems of affecting evenness quality, affecting dyeing quality, uneven hair ball tension, etc., to improve the quality of ball formation , The structure of the mechanism is simple, and the effect of reducing the cost of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

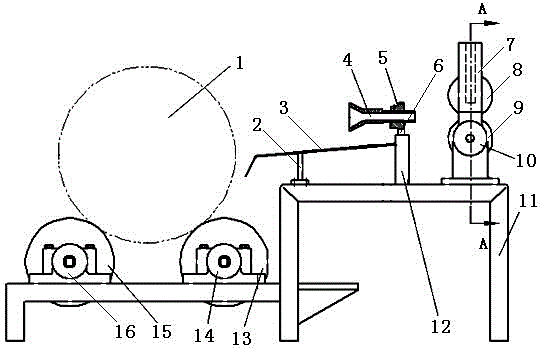

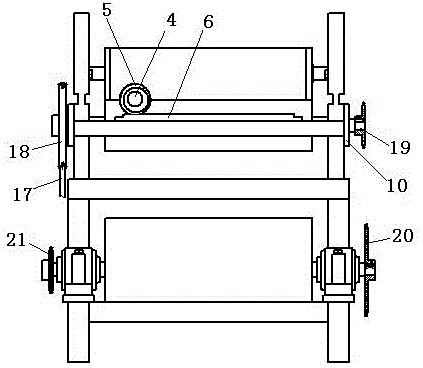

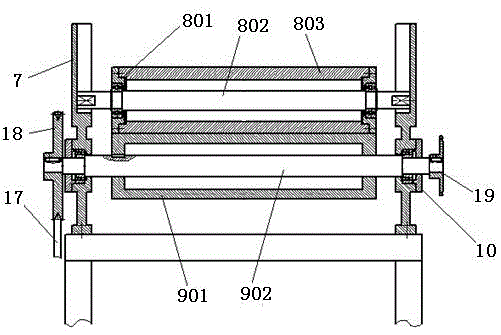

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0025] see figure 1 , 2 As shown, a winding mechanism of a pinecone machine includes a stepped frame 11, a pallet support frame 2, a rack support 12 and a roll seat 7 are sequentially fixed on the high table of the frame 11; The pallet support frame 2 is provided with a pallet 3; the rack support 12 is provided with a false twist mechanism composed of a false twist horn 4, a gear 5 and a rack 6, and the rack 6 is installed on the On the rack support 12, the gear 5 is fixed on the false-twist horn 4, and the false-twist horn 4 is installed in the hole of the guide plate of the rowing mechanism, and can rotate positively and negatively in the hole. The gear 5 and the rack 6 are meshed with each other; the upper end of the roll seat 7 is equipped with a strip pressure roller 8, and the lower end of the roll seat 7 is equipped with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com