Water-gas separation vacuum pre-pressing method and device

A vacuum preloading method and water-air separation technology, which is applied in the fields of soil protection, construction, infrastructure engineering, etc., to achieve the effect of improving the vacuuming effect and saving construction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

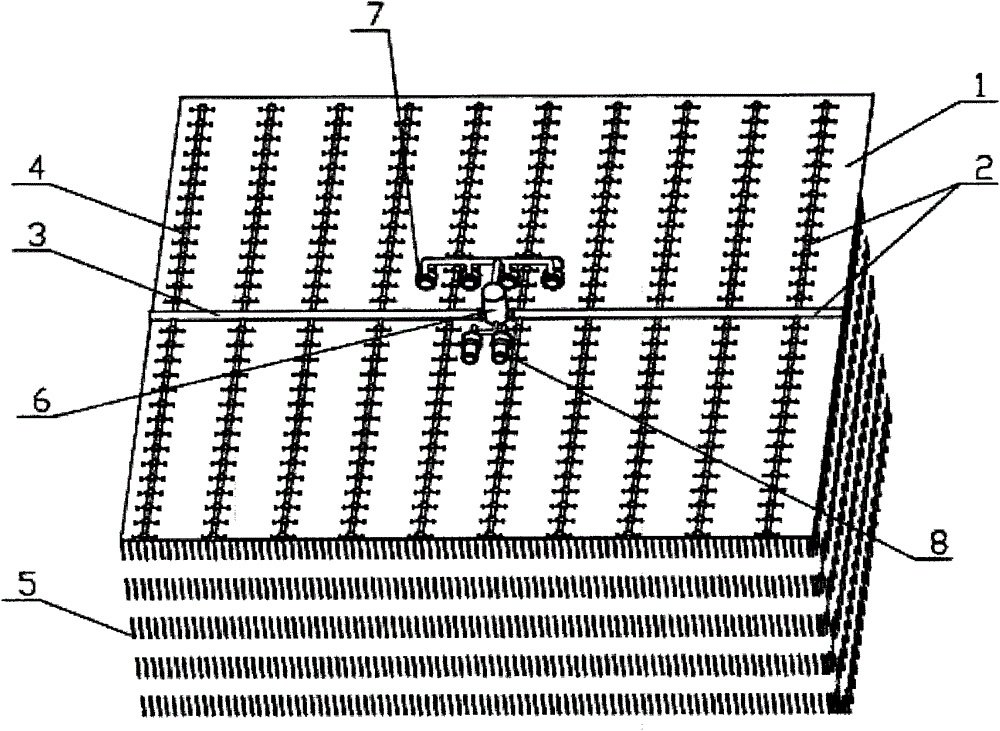

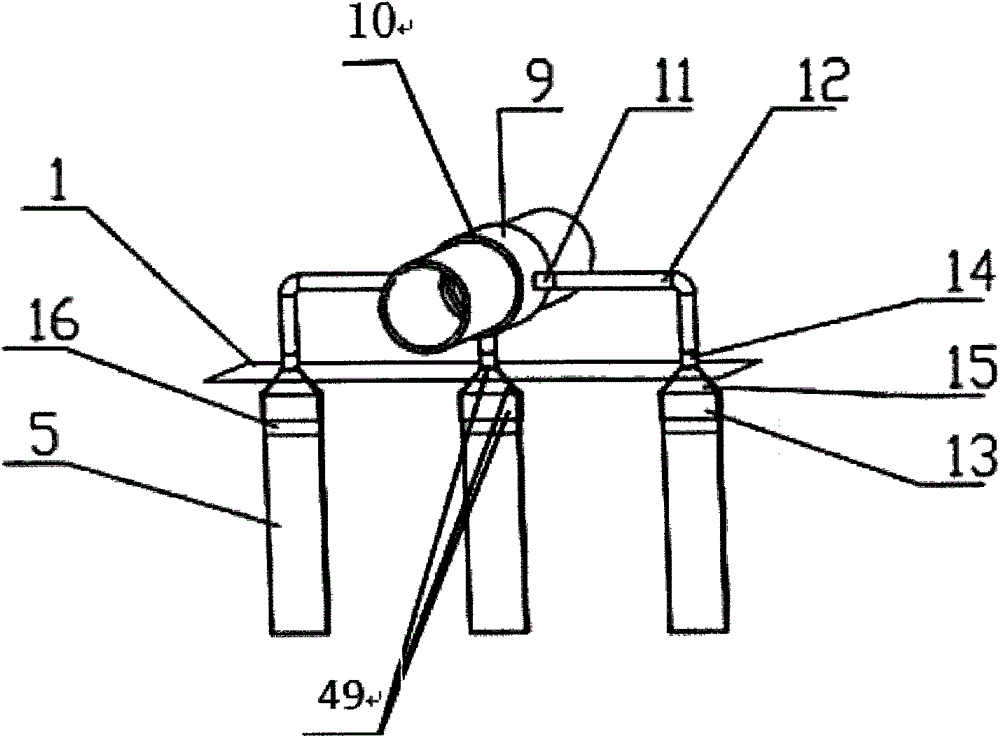

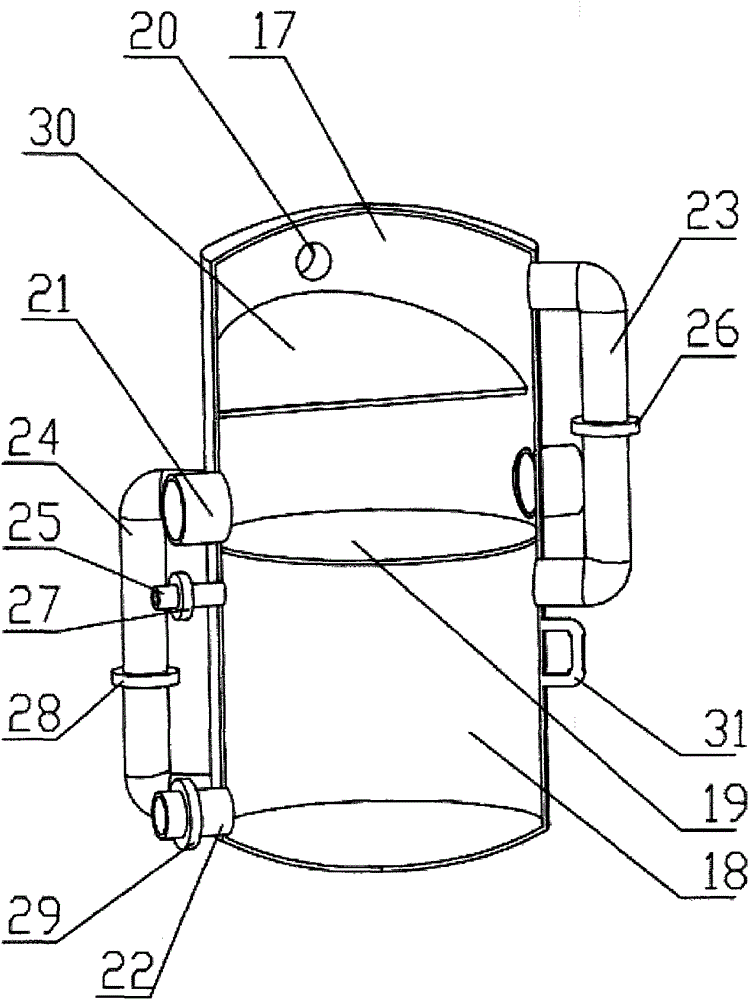

[0081] This embodiment illustrates the technical solutions of the water-gas separation vacuum preloading method, the three-piece connection device and the sub-compartment type water-gas separation tank with the water-gas separation pipeline connected to the plastic drainage board with reference to the accompanying drawings.

[0082] Figure 1 or figure 2 or image 3 As shown, a rectangular soft foundation treatment area with an area of 200m×200m and a total area of 40,000 m2 is used for water-gas separation vacuum preloading, and the vacuum degree under the vacuum sealing film is required to reach 80Kpa.

[0083] When the plastic drainage board 5 is constructed in the soft foundation treatment area according to the traditional vacuum preloading construction method, the plastic drainage board 5 is inserted in parallel in a square at a distance of 1m×1m along one side of the rectangular site.

[0084] The connection between the plastic drainage board 5 and the branch pipe 4...

Embodiment 2

[0115] This embodiment describes the technical scheme of installing the water-gas separation pipeline 2 in the construction of the water-gas separation vacuum preloading method in which the branch pipe 4 of the water-gas separation pipeline 2 is connected to the vacuum tube 46 under the vacuum sealing film 1 in conjunction with the accompanying drawings. In this embodiment, the installation of the water-gas separation tank 6, the vacuuming device 7 and the water pumping device 8, as well as the construction of the vacuuming and drainage consolidation operations are carried out with reference to the technical scheme of the first embodiment.

[0116] Such as Figure 4 or Figure 5 As shown, a rectangular soft foundation treatment area with an area of 100m×200m and a total area of 20,000 m2 is used for water-gas separation vacuum preloading, and the vacuum degree under the vacuum sealing membrane 1 is required to reach 80Kpa.

[0117] According to site conditions and design ...

Embodiment 3

[0123] This embodiment illustrates the technical scheme of installing the water-gas separation pipeline 2 in the construction of the water-gas separation vacuum preloading method in which the branch pipe 4 of the water-gas separation pipeline 2 is connected to the filter tube 44 under the vacuum sealing film 1 in conjunction with the accompanying drawings. In this embodiment, the installation of the water-gas separation tank 6, the vacuuming device 7 and the water pumping device 8, as well as the construction of the vacuuming and drainage consolidation operations are carried out with reference to the technical scheme of the first embodiment.

[0124] Such as Figure 6 or Figure 7 As shown, for a rectangular soft foundation treatment area with an area of 50m×100m and a total area of 5000㎡, vacuum preloading for water and gas separation is required, and the vacuum degree under the vacuum sealing membrane 1 is required to reach 80Kpa.

[0125] According to site conditions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com