Rigid connection method for prestressed concrete pile end plates

A concrete pile and rigid connection technology, applied in the field of pile foundation in the construction field, can solve problems such as reducing welding strength, non-compliance with regulations, and cracks in end plates, so as to improve construction speed, improve processing speed and quality, and reduce machining costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the above-mentioned drawings.

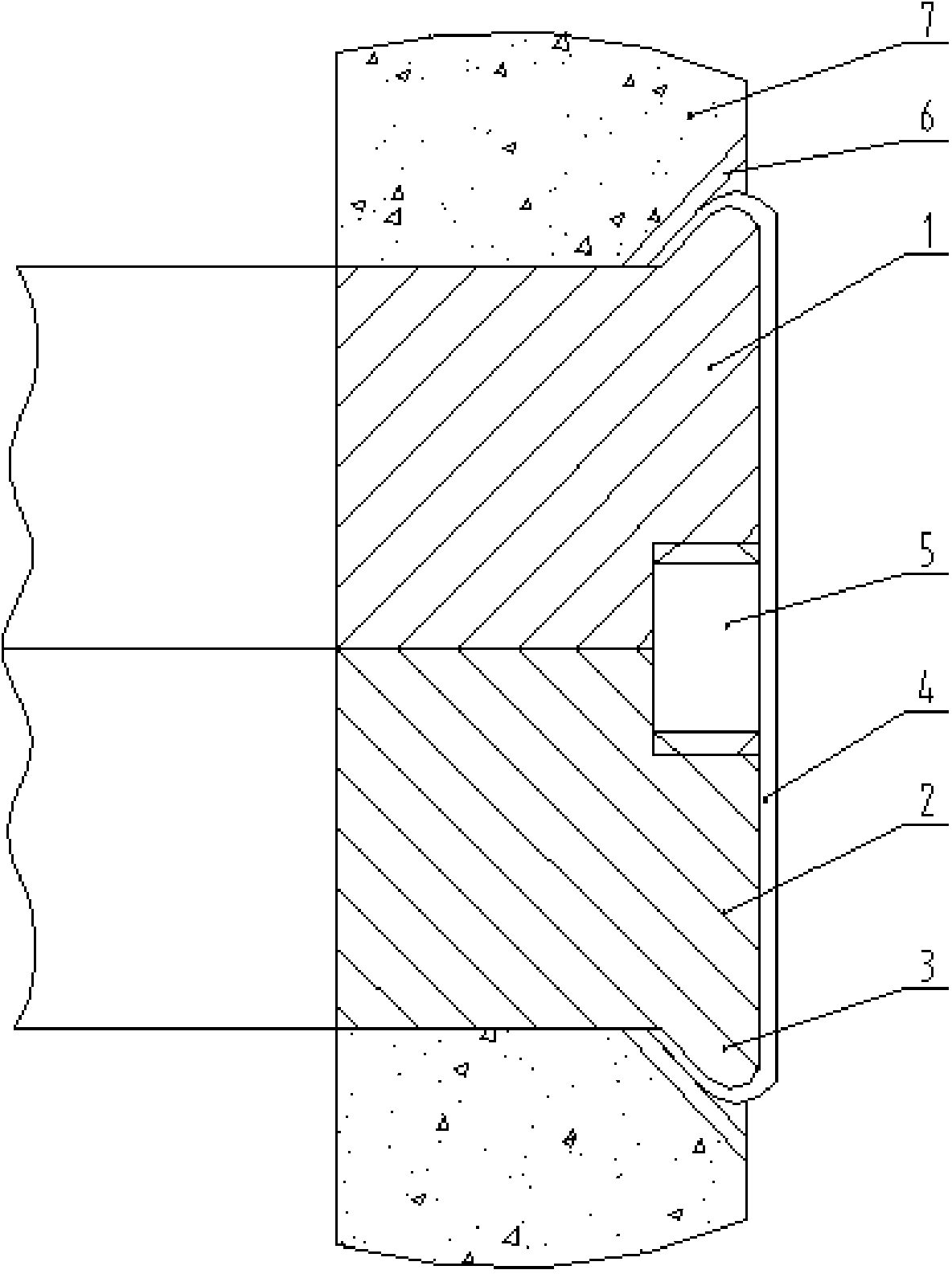

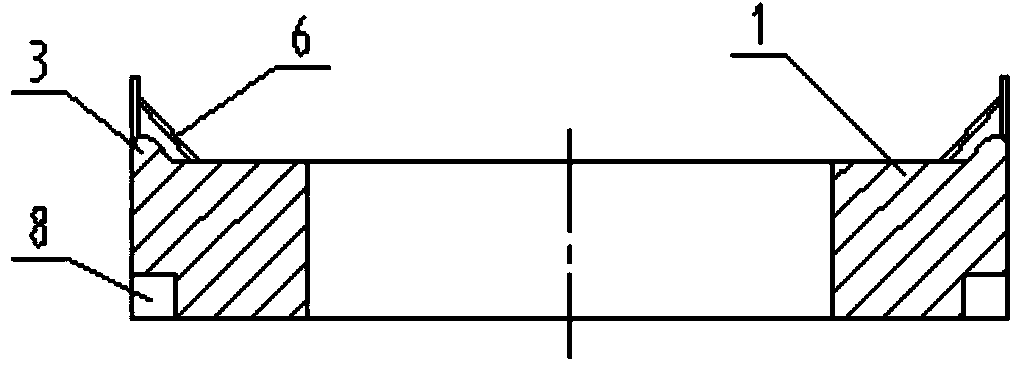

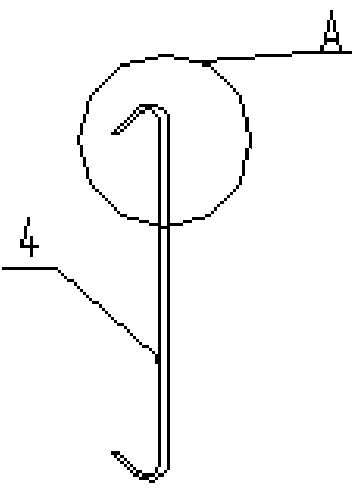

[0020] Such as Figure 1-8 Shown, the present invention is made up of concrete pile end plate and steel fastener etc. The end plates include the upper end plate 1 of the previous prestressed concrete pile 7 and the lower end plate 2 of the next prestressed concrete pile. The present invention improves the mold of the end plate manufacturer: it is pre-set in the molten steel casting mold for making the end plate, so that the end plate produced by the centrifugal production process becomes a flange 3 with a tensile function on the outer surface and a shear resistance on the inner surface. Features semicircular holes or trapezoidal grooves8. The improved mold can industrially produce a large number of end plates, which can save the repetitive labor and cost of machining each end plate in the old process.

[0021] At the construction site, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com