Bypass valve with hyperboloid structure

A hyperboloid, bypass valve technology, used in valve devices, internal combustion piston engines, engine components, etc., can solve the problems of severe wear of parts, large movement space, increased clearance in all directions, etc., to enhance structural strength and wear resistance. The effect of increasing the contact area and reducing the sports wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]

[0022] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

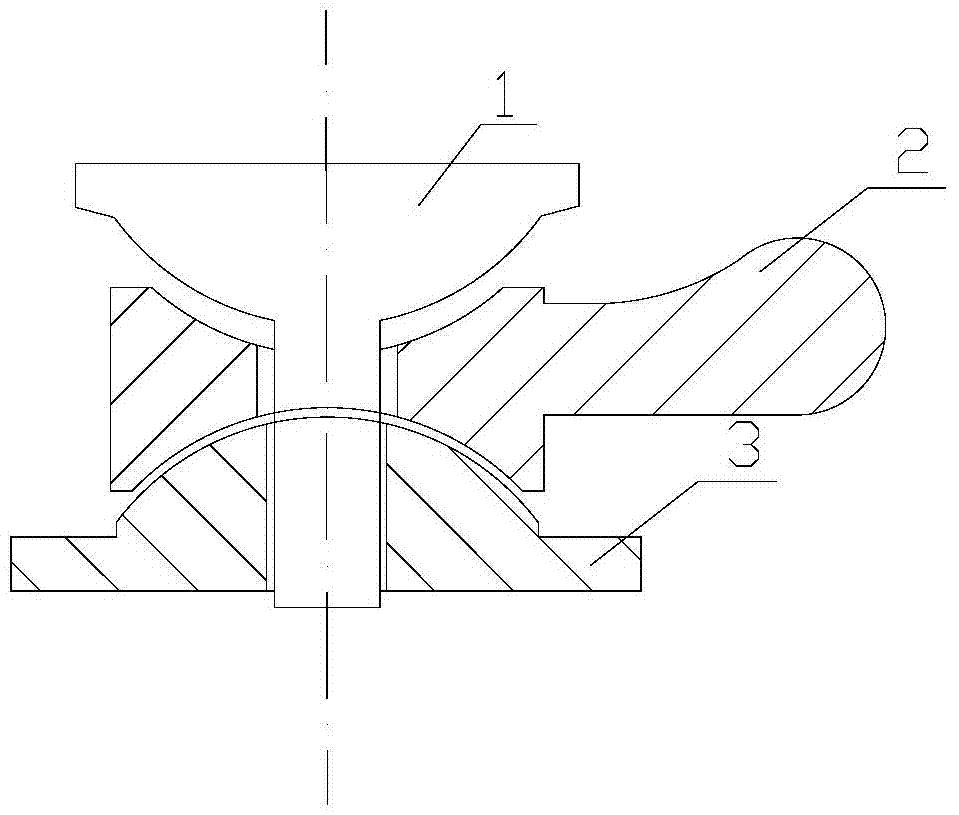

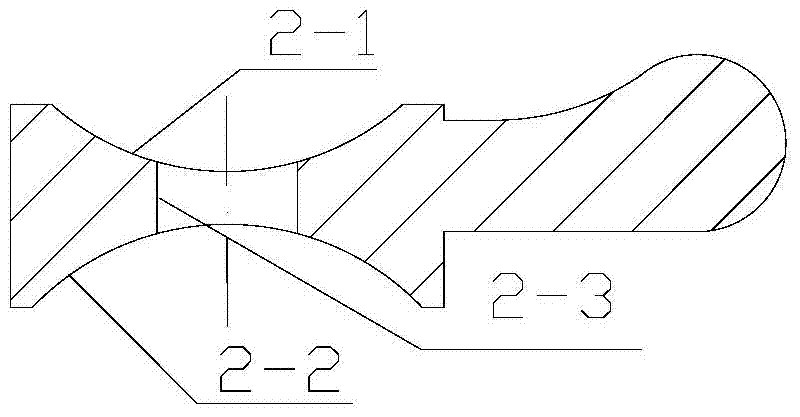

[0023] Such as Figure 1-Figure 4 As shown, it includes: a T-shaped pin 1, a hyperboloid rocker arm 2, and a valve plate 3 with a curved surface.

[0024] A hyperboloid structure bypass valve of the present invention includes a T-shaped pin 1, a hyperboloid rocker arm 2 and a valve plate 3 with a curved surface; the hyperboloid rocker arm 2 and the valve plate 3 with a curved surface pass through the T-shaped pin 1 connected into one.

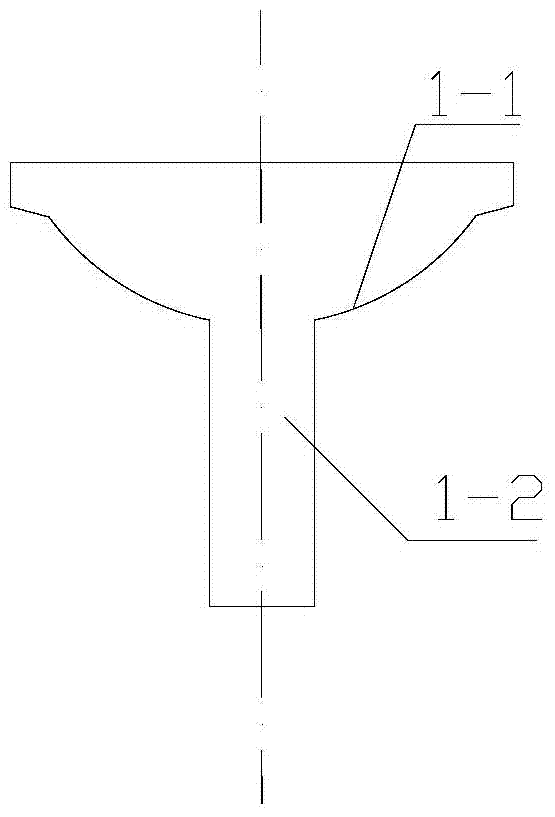

[0025] The T-shaped pin is composed of an upper spherical pin head 1-1 connected with a lower cylindrical rod 1-2. Among them, the upper spherical pin head 1-1 is the main stress feature, and the design of the spherical surface effectively improves the force distribution of the contact surface and decomposes the wear of the contact point; the cylindrical rod 1-2 part is in the entire bypass valve structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com