Printing device of SLM equipment

A printing device and equipment technology, which is applied in the direction of improving process efficiency, additive processing, and energy efficiency, can solve problems such as difficult to meet axisymmetric, improve the mechanical properties of materials and structures, improve the quality of scraping powder, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

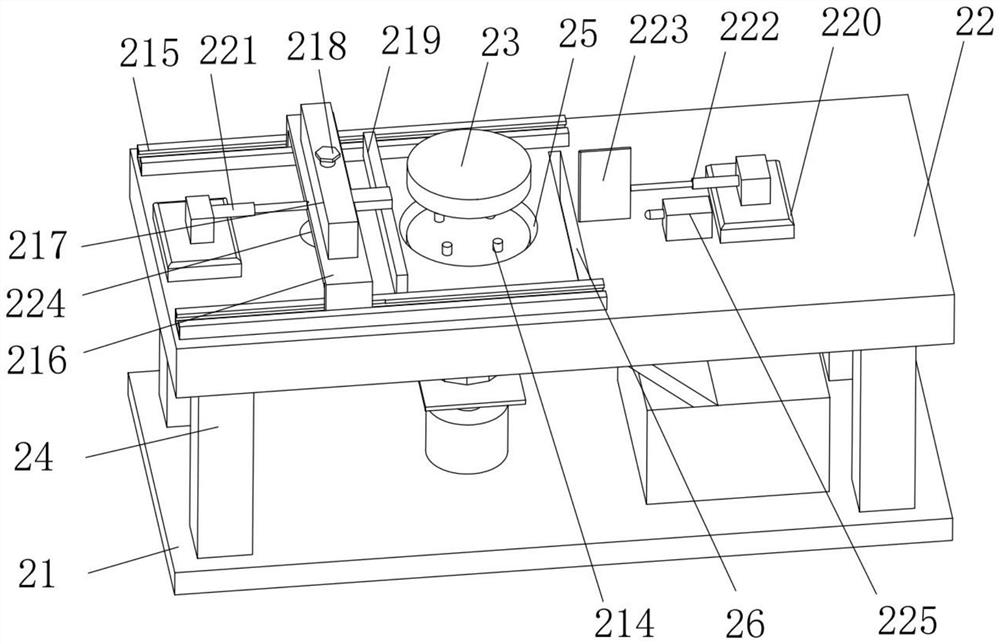

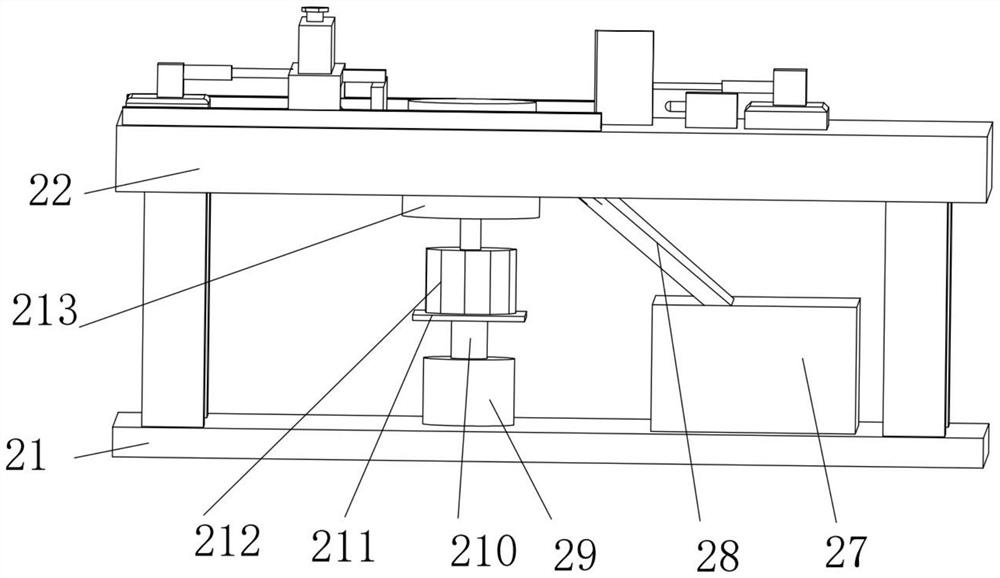

[0048] Such as Figures 1 to 7 As shown, a printing device of SLM equipment, including a substrate, a worktable, and a printing round table;

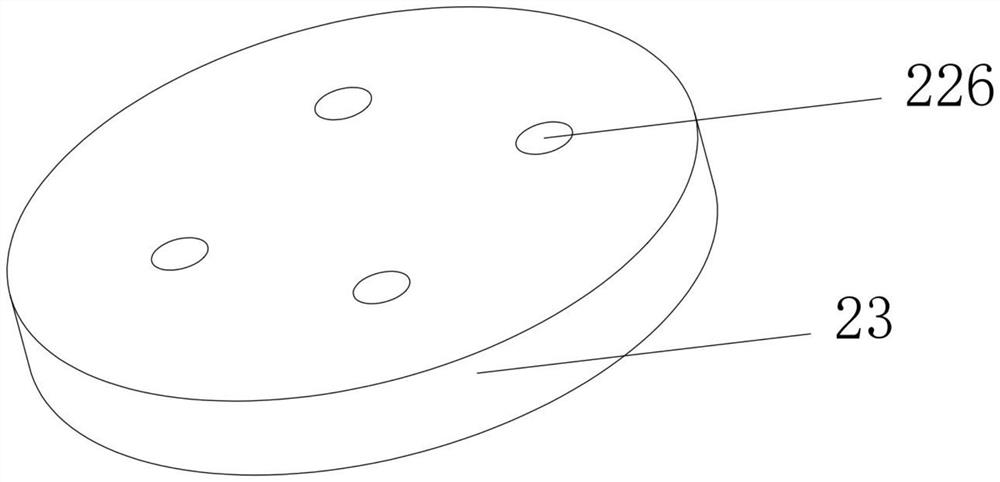

[0049] The four corners of the upper surface of the substrate are fixedly connected with support columns, the workbench is fixedly connected to the upper surface of the support columns, a circular through hole is opened in the middle of the upper surface of the workbench, and the workbench The surface is located on the right side of the circular through hole, and a material leakage hole is opened. The right side of the upper surface of the substrate is fixedly connected with a collection box. A hydraulic cylinder is fixedly connected in the middle of the surface, the output end of the hydraulic cylinder is fixedly connected with a hydraulic rod, and the upper end of the hydraulic rod is fixedly connected with a loading plate, and a motor is fixedly installed on the upper surface of the loading plate, and the motor The output end of the...

Embodiment 2

[0052] Such as Figures 1 to 7 As shown, a printing device of SLM equipment includes a substrate, a worktable, and a printing round table. Support columns are fixedly connected to the four corners of the upper surface of the substrate, and the workbench is fixedly connected to the upper surface of the support column. The upper surface of the workbench There is a circular through hole in the middle of the surface, and a material leakage hole is opened on the upper surface of the workbench on the right side of the circular through hole. The middle of the upper surface of the substrate is fixedly connected with a hydraulic cylinder, the output end of the hydraulic cylinder is fixedly connected with a hydraulic rod, the upper end of the hydraulic rod is fixedly connected with a loading plate, the upper surface of the loading plate is fixedly installed with a motor, and the output of the motor The end is fixedly connected with a cylindrical shaft, and the printing round table is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com