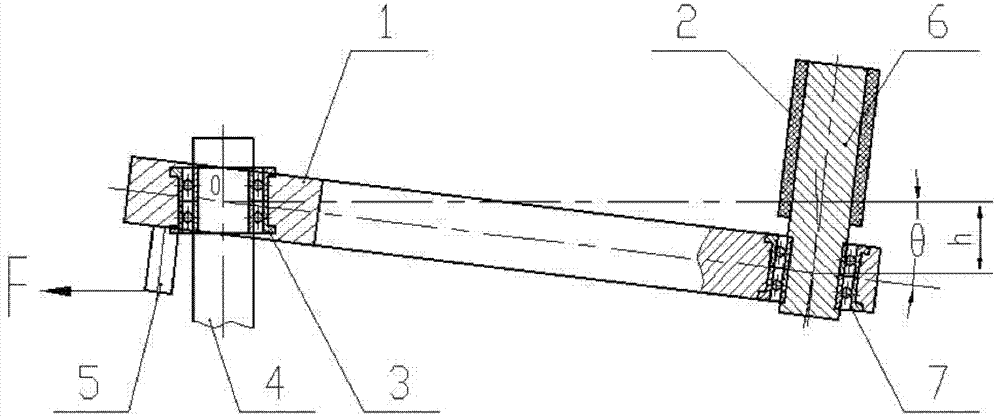

Locating and clamping mechanism of screen printing machine

A technology of screen printing machine and clamping mechanism, which is applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problem of increasing the overall installation error of the clamping mechanism, increasing the installation error of the clamping mechanism, and θ angle and distance increase, to achieve the effect of shortening the maintenance cycle, reducing the difficulty of maintenance, and reducing the fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

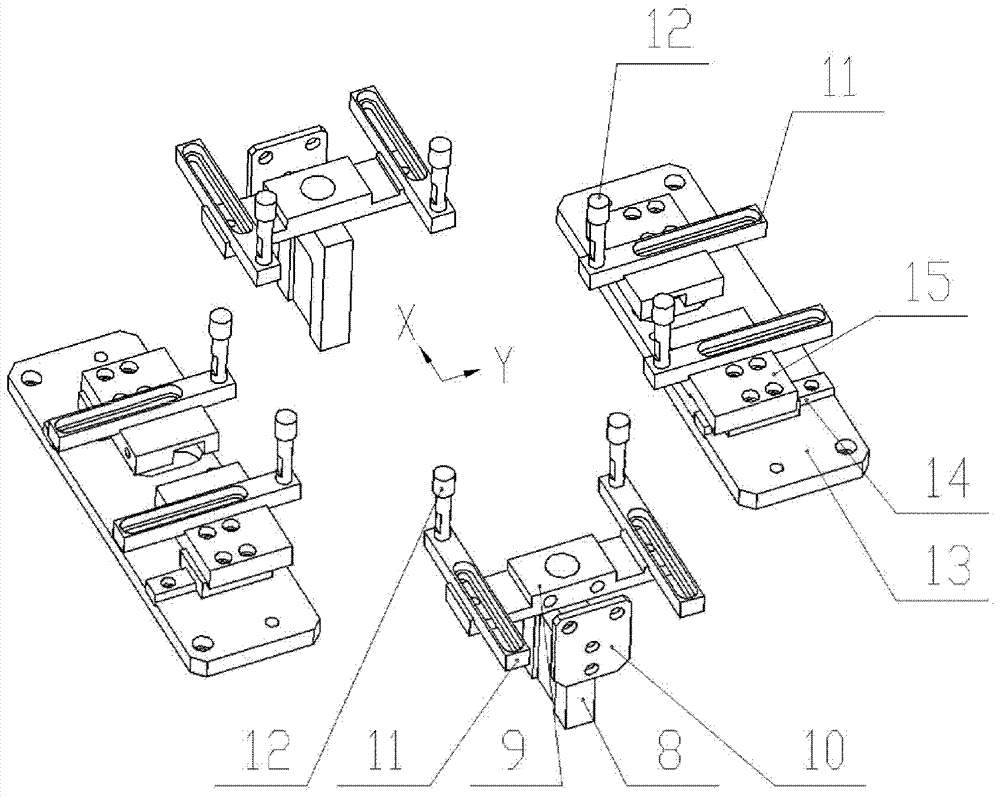

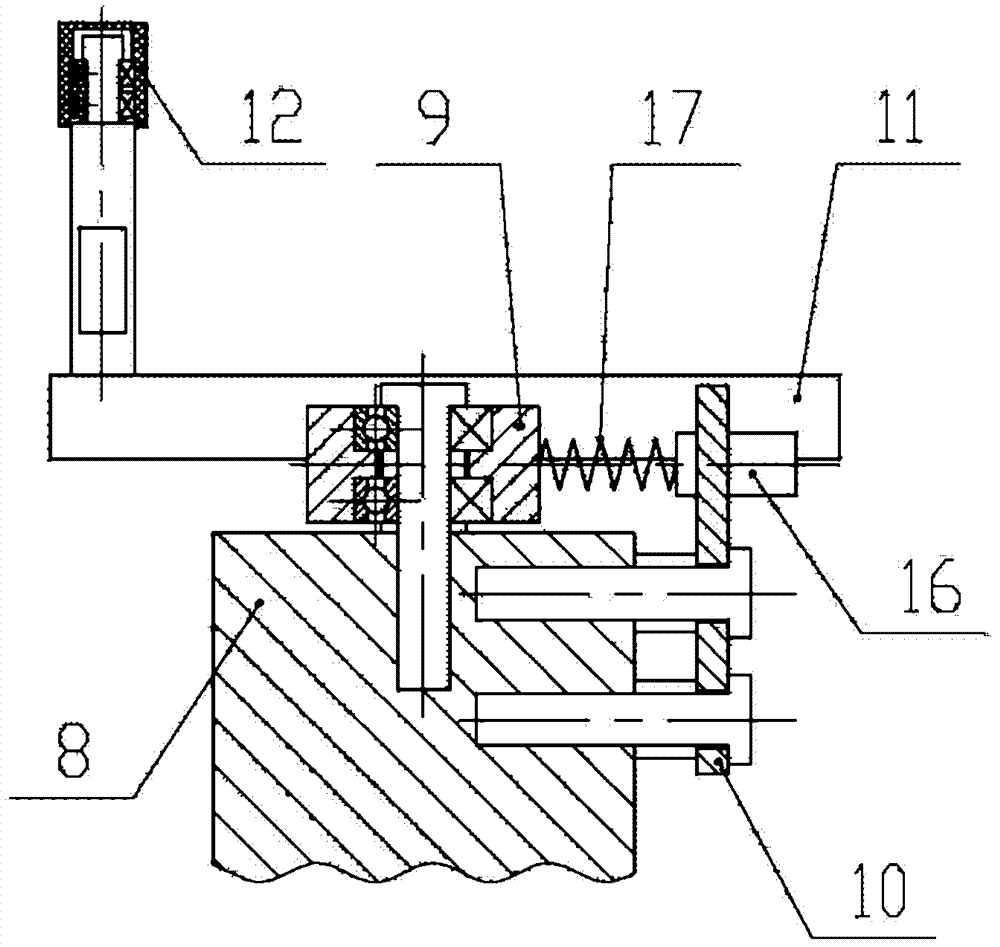

[0038] A positioning and clamping mechanism for a screen printing machine, such as figure 2 and image 3 As shown, the clamping mechanism in the X direction has a driving base 8, which is driven by the positioning transmission mechanism of the screen printing machine, and the whole reciprocates in the X direction. The self-balancing rotating base 9 is connected with the drive base 8 through short-head screws, two bearings and gaskets, so that the self-balancing rotating base 9 can rotate around the short-head screws. The spring baffle plate 10 is connected with the drive base 8 through two spacers, and is equipped with two convex head screws 16 at the same time. The end acts on the self-balancing rotating base 9 through the tension spring 17, and the elastic force of the tensioning spring 17 is changed by adjusting the convex head screw 16, so that the self-balancing rotating base 9 is in a balanced position. The adjusting rod 11 is fixed in the slot of the self-balancing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com