Anti-loose tire bolt

A technology for anti-loosening and tires, applied in the direction of bolts, screws, nuts, etc., can solve the problems of cumbersome processing technology, complex structure, low strength, etc., and achieve the effect of overcoming complex structure, simple assembly process and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

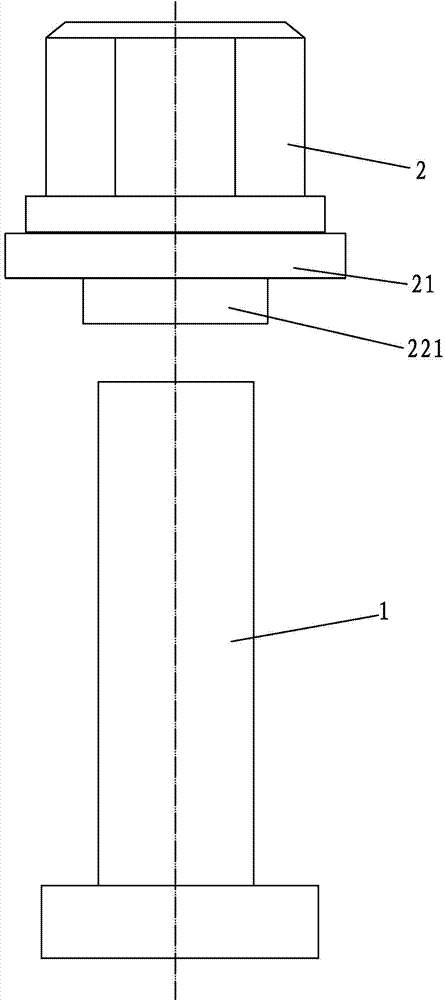

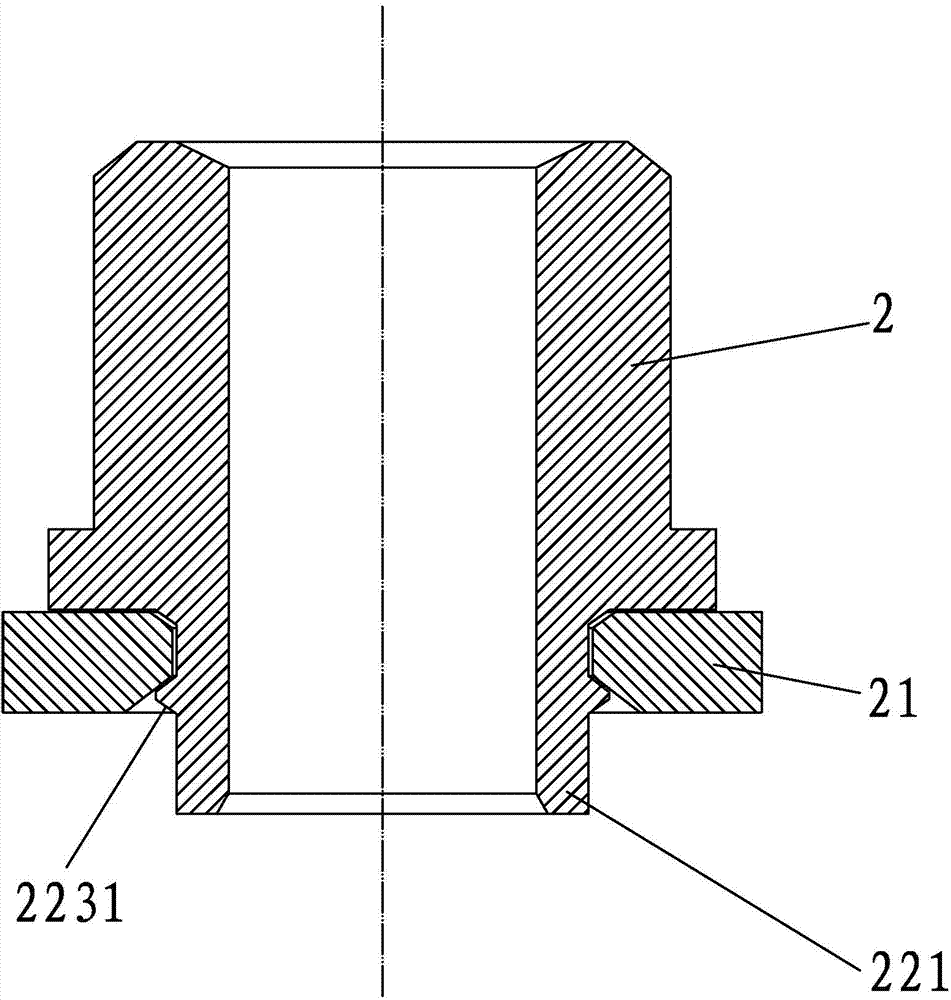

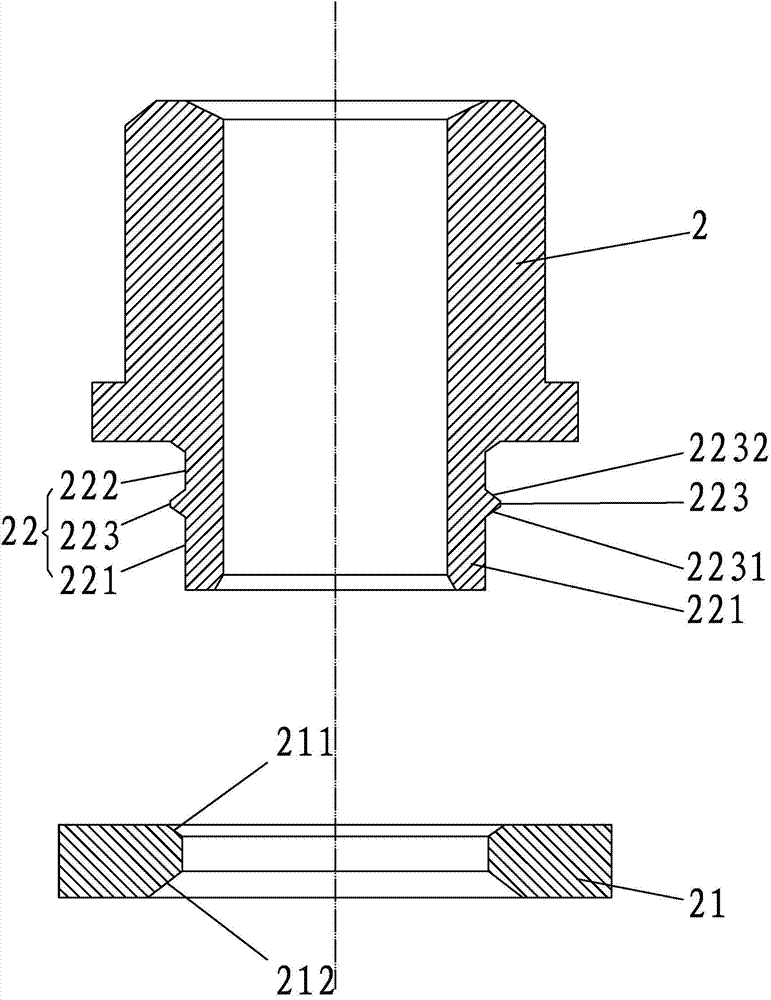

[0026] A kind of anti-loosening tire bolt of the present invention, as Figure 1-4 As shown, including screw 1 and nut 2.

[0027] The nut 2 is matched with the screw rod 1, and the nut 2 is equipped with a movable washer 21 between the nut 2 and the wheel hub. Relative rotation; the end of the nut 2 is formed with a flange 22, and the end section 221 of the flange 22 is matched and inserted between the screw rod 1 and the corresponding bolt hole on the hub, because the gap between the corresponding bolt hole on the hub and the screw rod 1 is closed The end section 221 is filled, so that the contact area between the corresponding bolt hole on the wheel hub and the screw rod 1 increases without shaking, and the shear stress formed on the acting contact part is greatly reduced, which can avoid the phenomenon of tire bolts breaking to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com