Measuring point switching device used for voltage withstanding test of low-voltage switch appliance

A technology of withstand voltage testing and switching devices, which is applied in the direction of measuring device shells, testing dielectric strength, and improving basic electrical components, etc., which can solve problems such as the influence of measurement accuracy, measurement power fluctuations, and considerable time spent, and achieve saving Effects of conversion time, increased measurement speed, and reduced adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

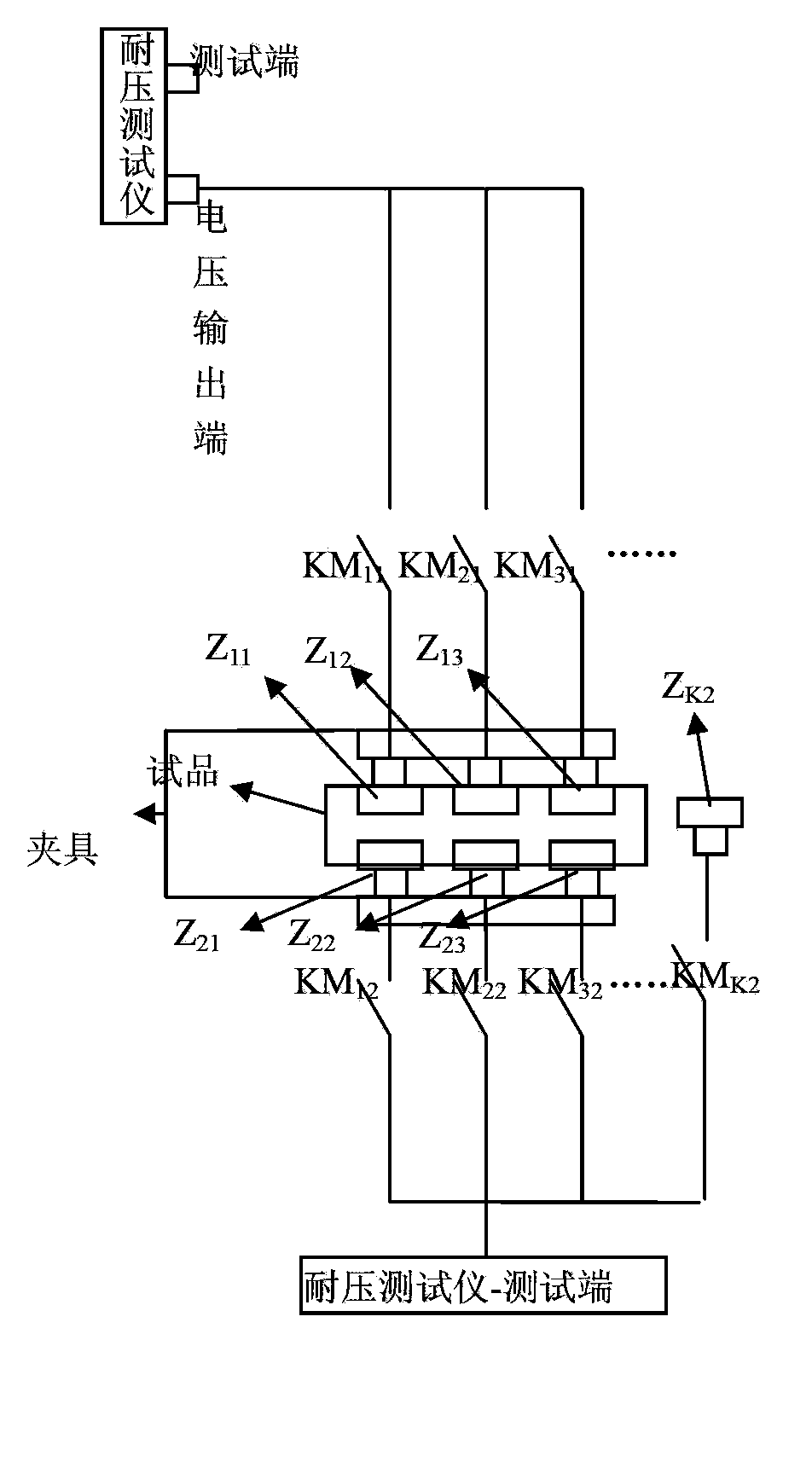

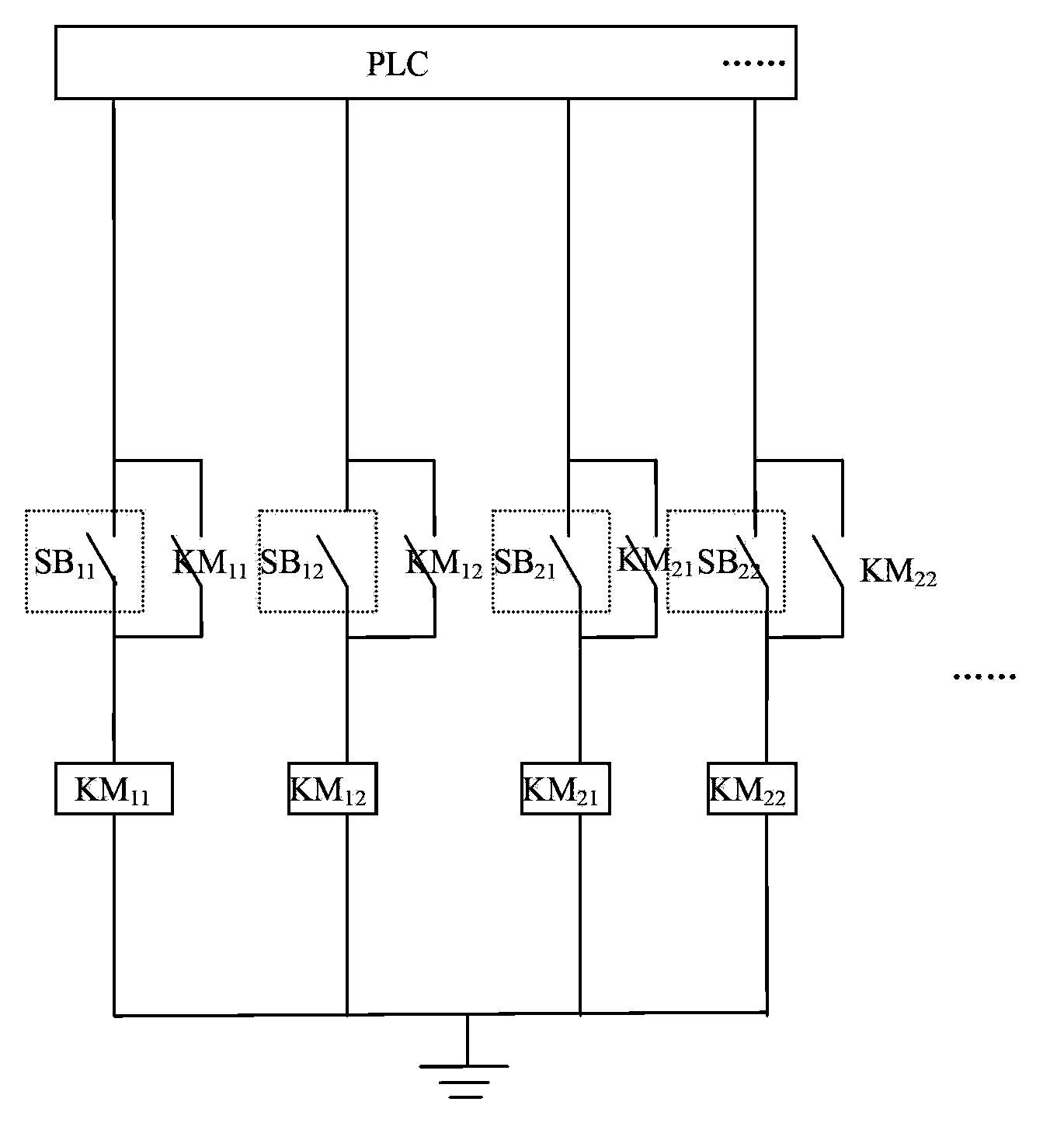

[0016] Such as figure 1 , figure 2 As shown, a measuring point switching device for withstand voltage test of low-voltage switchgear, including withstand voltage tester, connecting contact Z k2 , the first high-voltage relay, the second high-voltage relay, PLC and trigger switch, the voltage output end of the voltage withstand tester and the first contact (KM) of the first high-voltage relay 11 、KM 21 、KM 31 ) input terminal connection, the first contact of the first high voltage relay (KM 11 、KM 21 、KM 31 ) output terminal and the electrode claw (Z 11 ,Z 21 ,Z 31 ) connection, the first contact of the second high voltage relay (KM 12 、KM 22 、KM 32 ) input terminal and the electrode claw (Z 12 ,Z 22 ,Z 32 ) connection, the third contact KM of the second high voltage relay K2 Connecting contact Z with the housing of the switch k2 connected, its output end is connected to the test end of the withstand voltage tester, and the trigger switch (SB 11 , SB 12 , SB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com