Method for Monitoring Defect Detection Rate of Electron Beam Scanner

A technology of electron beam scanner and defect detection rate, which is applied in the direction of circuit, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve problems such as damage and unreliable monitoring methods, and achieve promotion and avoid defect detection Inaccurate rate and accurate monitoring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

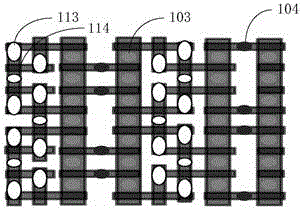

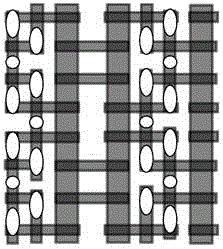

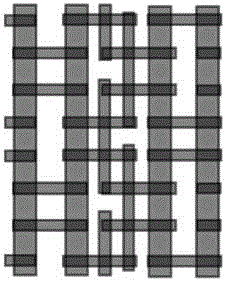

[0015] Such as figure 1 As shown, the method for monitoring the defect detection rate of an electron beam scanner provided by an embodiment of the present invention includes the following steps:

[0016] Step S10 , establishing three test units in the first area of the CMOS wafer, which are respectively the first, second and third test units, and each test unit includes an NMOS area and a PMOS area.

[0017] Wherein, the first region can be any region on the wafer, and its size is the same as that of a chip unit; in a preferred embodiment, the first region is located on the dicing lane of the wafer. Establishing test units on the dicing lanes of the wafer does not occupy the position of valid chip units on the wafer and causes no waste. In the subsequent process, when the wafer is diced, the test unit is destroyed.

[0018] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com