Solar cell panel assembly

A technology of solar panels and components, which is applied in the field of solar energy, can solve the problems of poor performance of solar cells, etc., and achieve the effect of improving performance and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

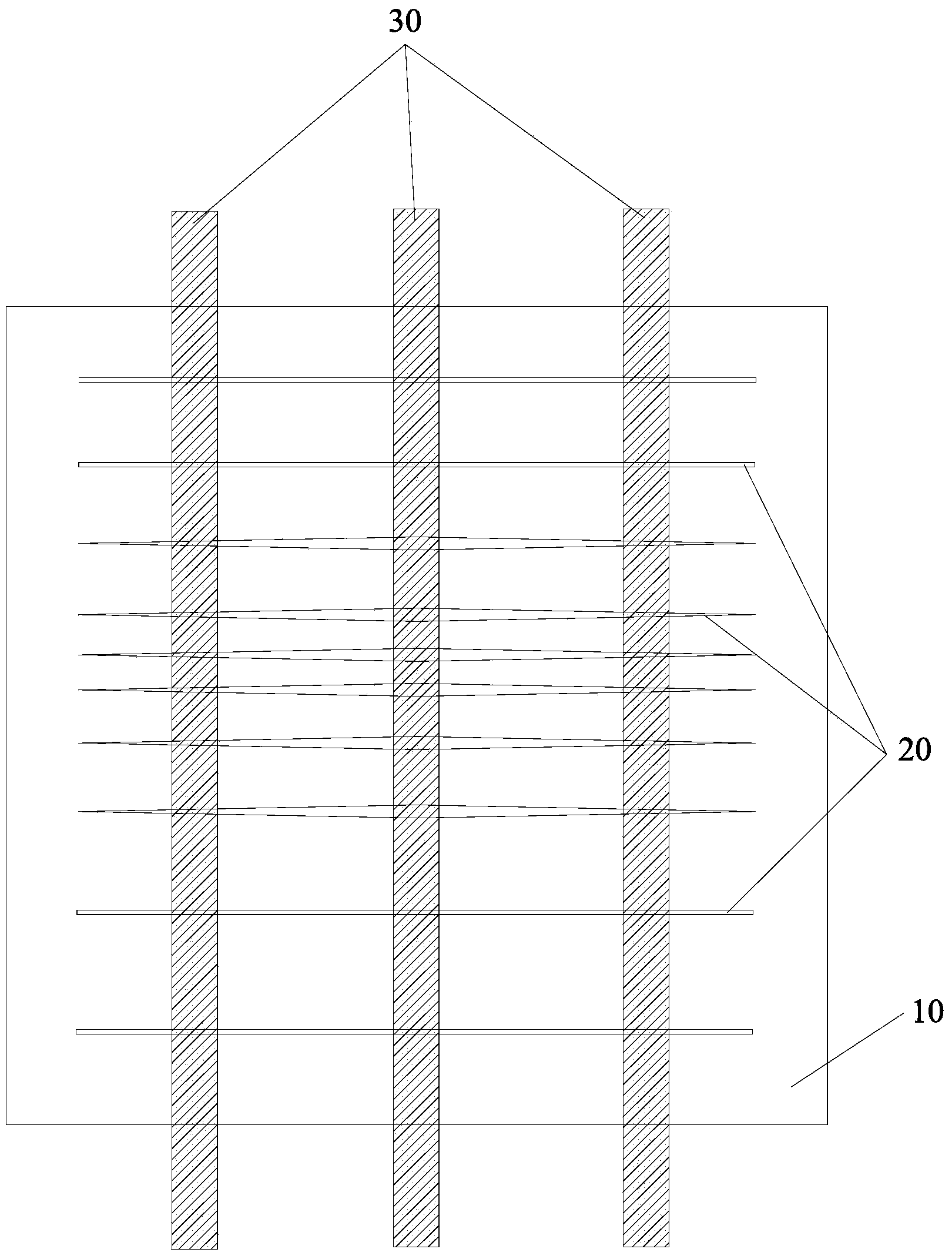

[0030] Example 1: The average square resistance is 90 ohms, the square resistance value range in a single silicon chip is 70 ohms-110 ohms, the total number of grid lines in the screen pattern is 100-110, and the number of grid lines in the central high square resistance area is 40 -50 wires, the grid line interval is 1.102-1.384mm, and the width is 30um-35um. The number of grid lines in the surrounding area is 50-60, the interval is 1.678-2.02mm, and the width is 35-45um.

example 2

[0031] Example 2: The average square resistance is 100 ohms, the square resistance value range in a single silicon chip is 80 ohms-120 ohms, the total number of grid lines in the screen pattern is 110-120, and the number of grid lines in the central high square resistance area is 50 -60 pieces, the interval is 0.915-1.102mm, and the width is 30um-35um. The number of grid lines in the surrounding area is 60-70, the interval is 1.435-1.678mm, and the width is 35-45um.

example 3

[0032] Example 3: The average square resistance is 110 ohms, the square resistance value range in a single silicon chip is 90 ohms-130 ohms, the total number of grid lines in the screen pattern is 110-130, and the number of grid lines in the central area is 60-70 , the interval is 0.783-0.915mm, and the width is 30um-35um. The number of grid lines in the surrounding area is 50-60, the interval is 1.678-2.02mm, and the width is 35-45um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com