Electronic device

A technology for electronic devices and electronic components, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of rising shell temperature, small internal space of electronic products, affecting consumer use, etc., and achieves good thermal insulation effect, small thermal conductivity, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

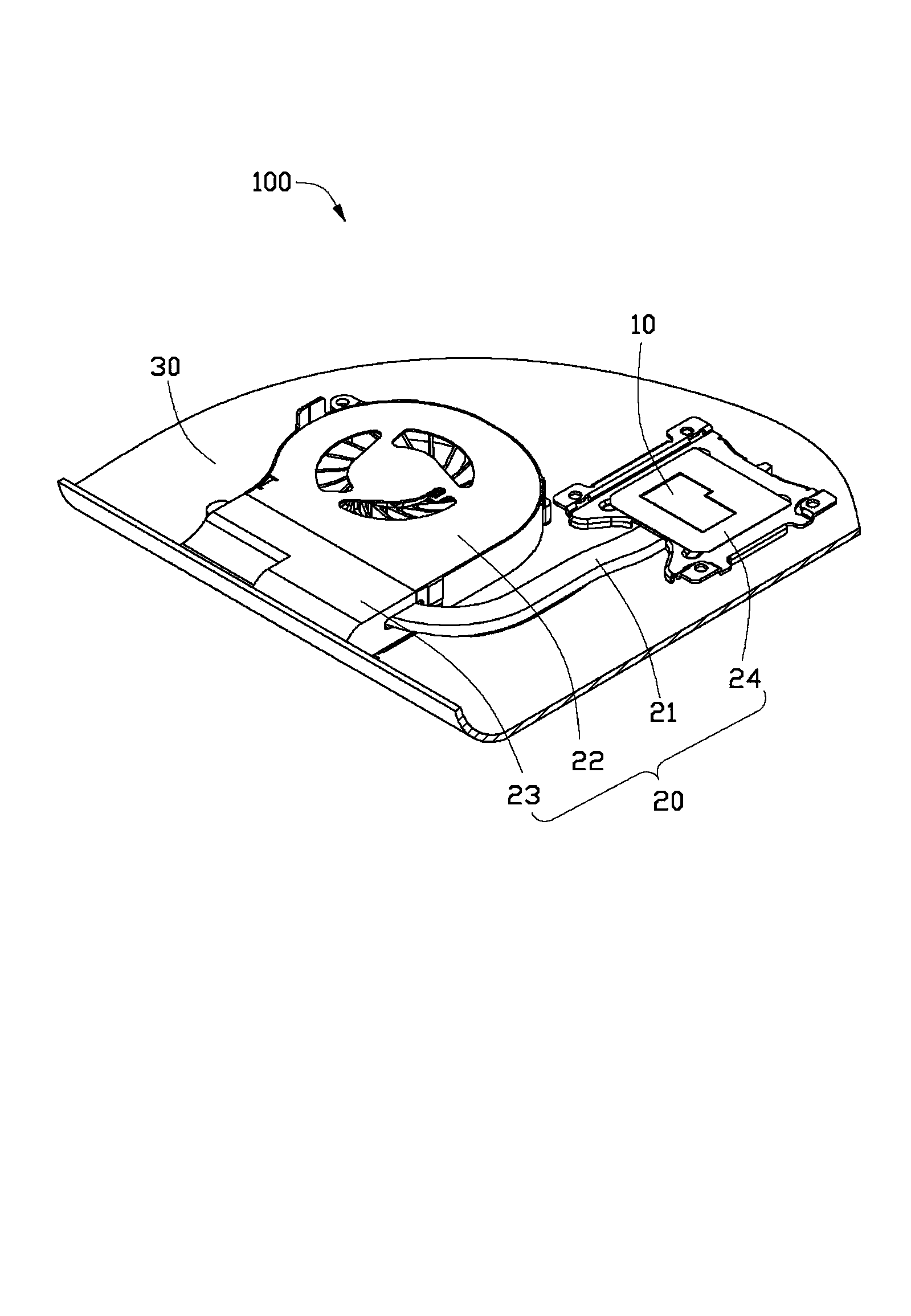

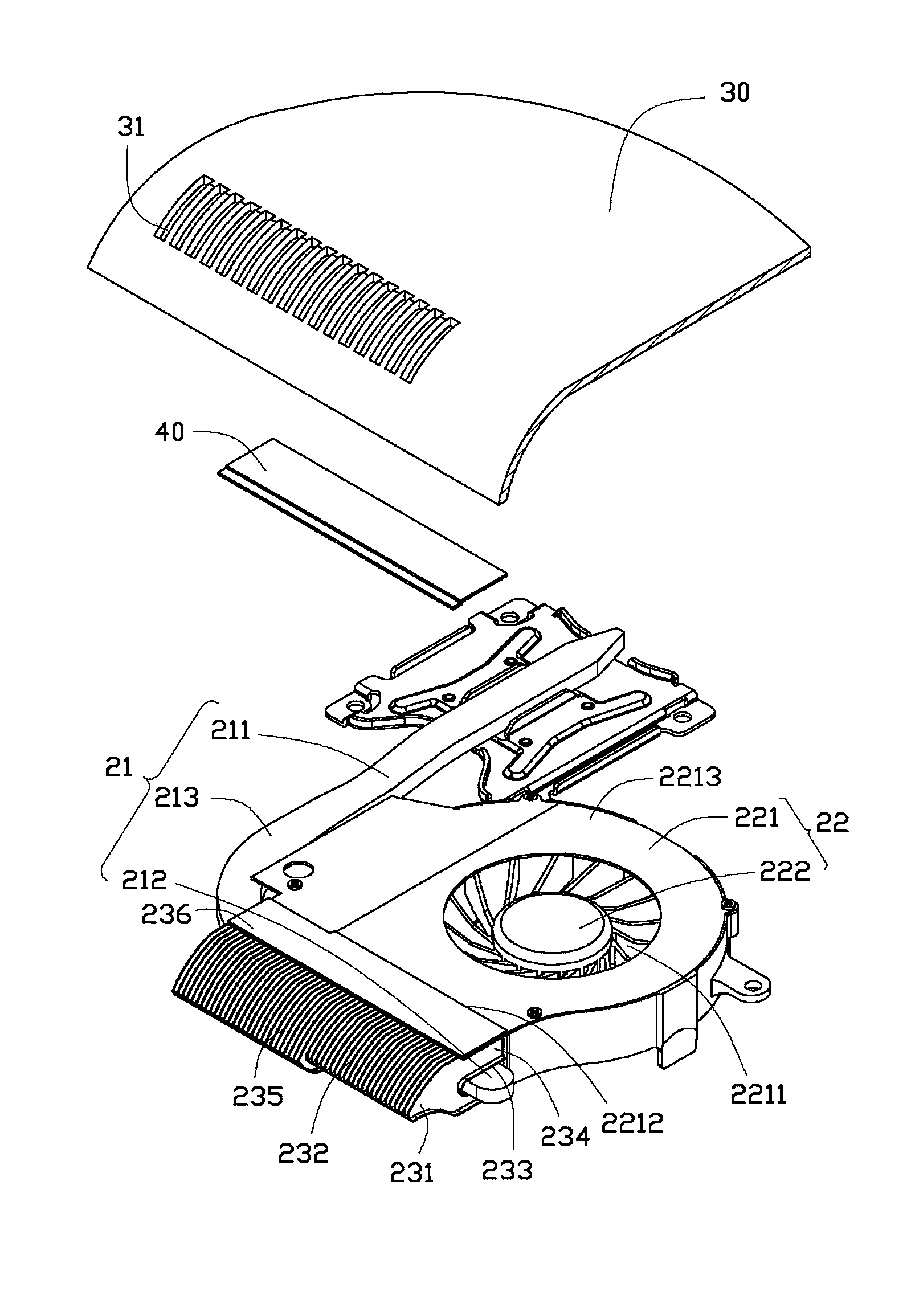

[0013] like figure 1 and figure 2 As shown, an electronic device 100 according to an embodiment of the present invention includes a heat-generating electronic component 10 , a heat-dissipating device 20 , a casing 30 and a heat-insulating layer 40 .

[0014] The heat dissipation device 20 is used for dissipating heat from the heat-generating electronic component 10 . The heat dissipation device 20 includes a centrifugal fan 22 , a heat pipe 21 around the centrifugal fan 22 , a cooling fin set 23 in thermal contact with one end of the heat pipe 21 , and a heat absorbing plate 24 attached to the heat-generating electronic component 10 .

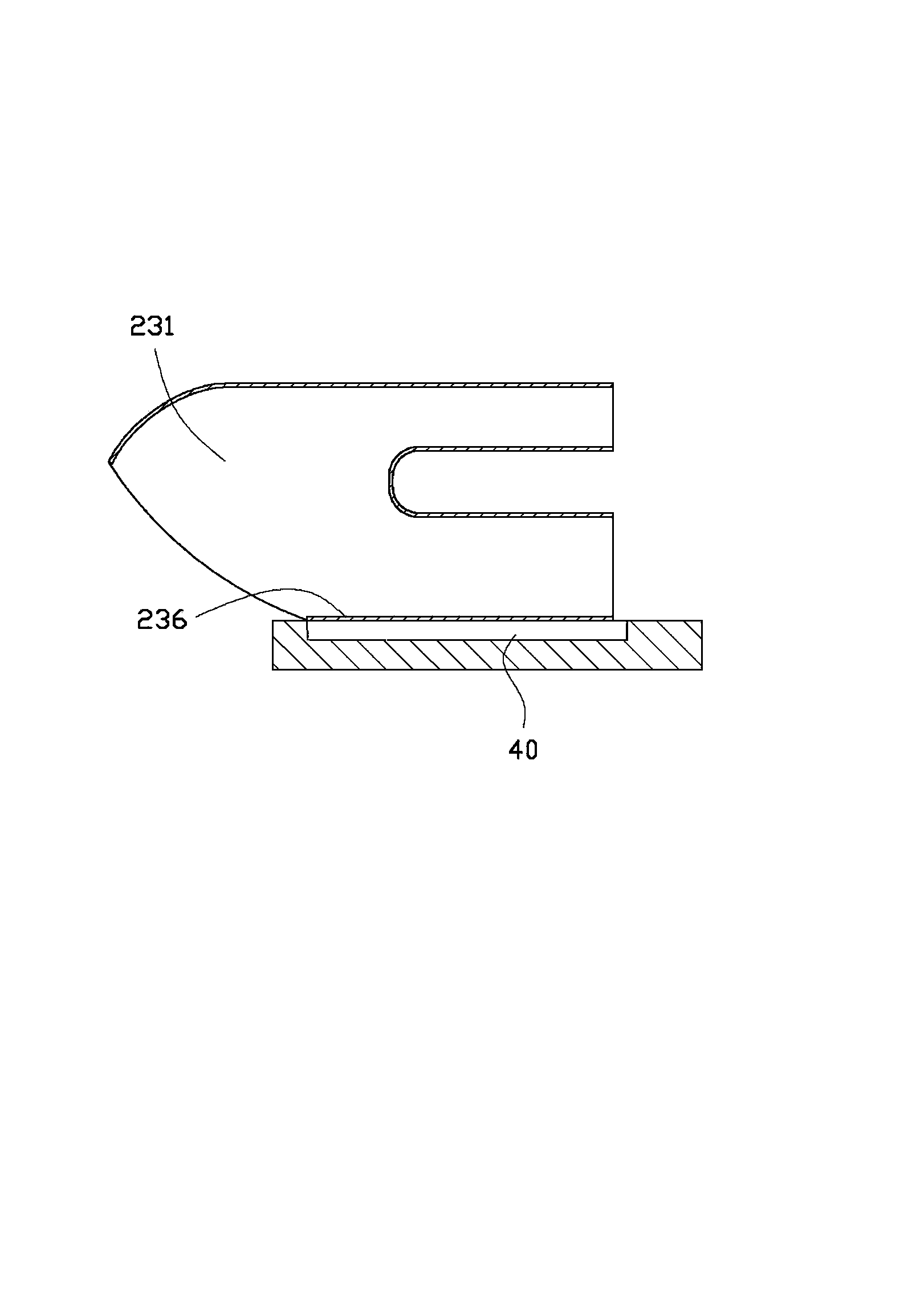

[0015] The heat pipe 21 is L-shaped and flat, and includes an evaporating section 211 , a condensing section 212 and a connecting section 213 connecting the evaporating section 211 and the condensing section 212 .

[0016] The centrifugal fan 22 includes a frame body 221 and an impeller set 222 disposed in the frame body 221 . The frame bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com