A mechanical tobacco packing equipment for tobacco leaf curing

A link and mechanical technology, applied in the field of mechanized cigarette filling equipment, can solve problems such as difficulty in promoting cigarette frames, and achieve the effects of improving cigarette filling efficiency, reducing breakage rate, and improving baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

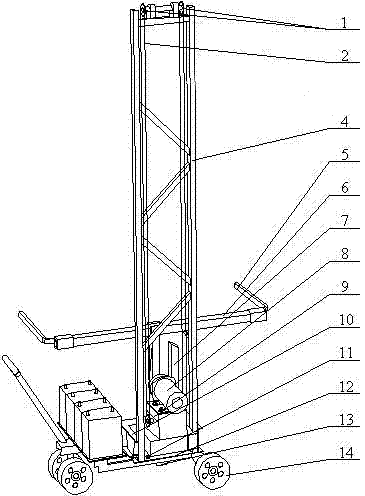

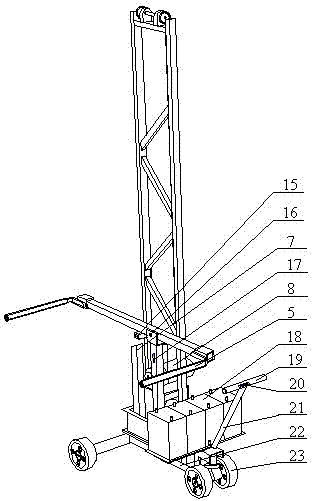

[0033] Such as figure 1 , 2 As shown, a kind of mechanized tobacco loading equipment for tobacco leaf curing links includes a moving device and a lifting device. The moving device includes a chassis 12, and the lower end of the chassis 12 is connected to the support frame 22 through the rotating shaft 13. The chassis 12 is also provided with The positioning pin 11 is movably connected with the support frame 22 through the chassis 12 . One end of the support frame 22 is provided with a directional wheel 14, and the other end is connected with the pull rod 21, the lower end of the pull rod 21 is connected with the steering wheel 23, and the upper end of the pull rod 21 is vertically provided with a handle 19. motor 8 and power supply 18, the motor 8 is connected with the second wheel 9 fixed on the chassis 12, the handle 19 is provided with an electric control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com