Protein protective agent for Pasteur inactivating human intravenous immunoglobulin and inactivation method of protein protective agent

A technology of human immunoglobulin and protein, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, antibodies, etc., can solve the problem of multimer increase, achieve the effect of protecting protein and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

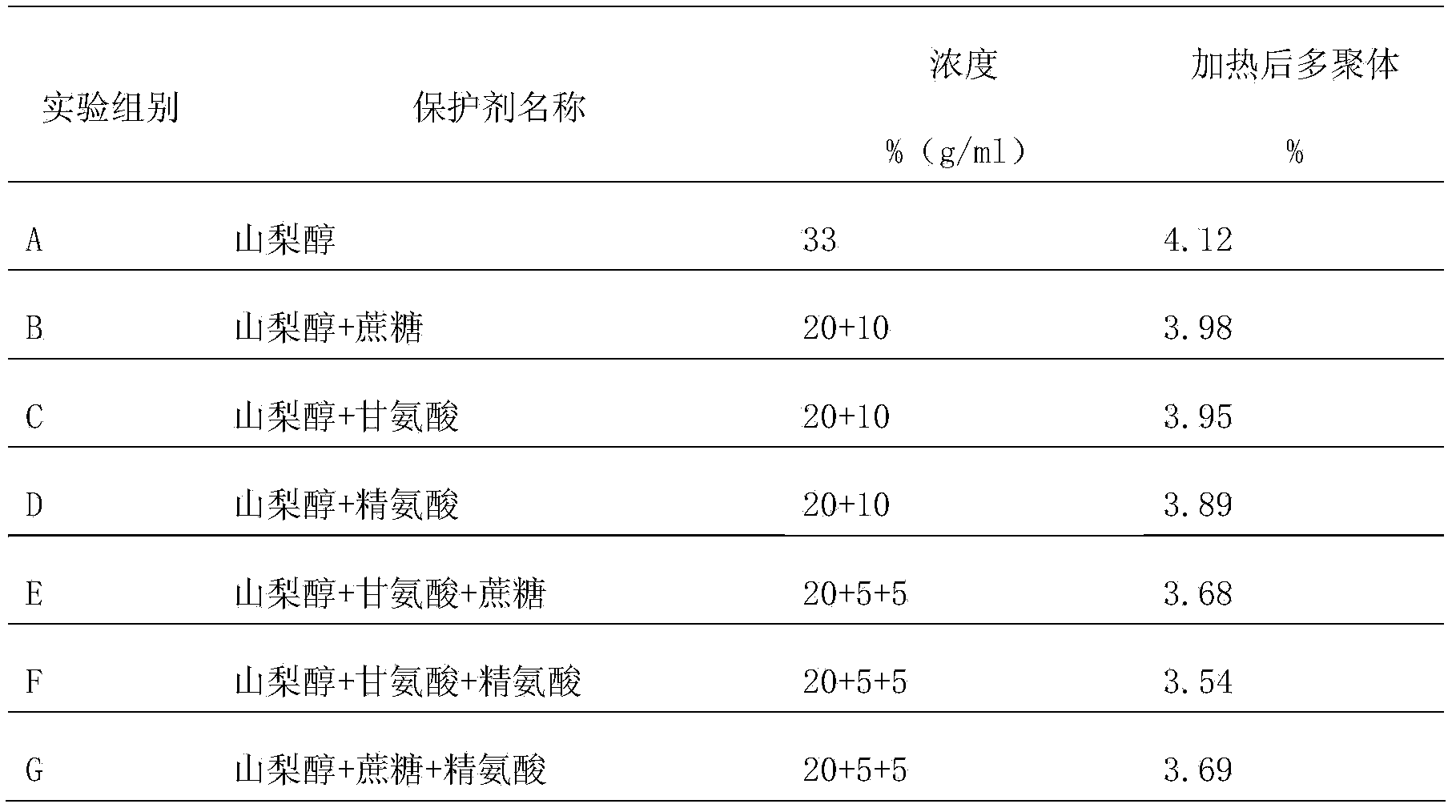

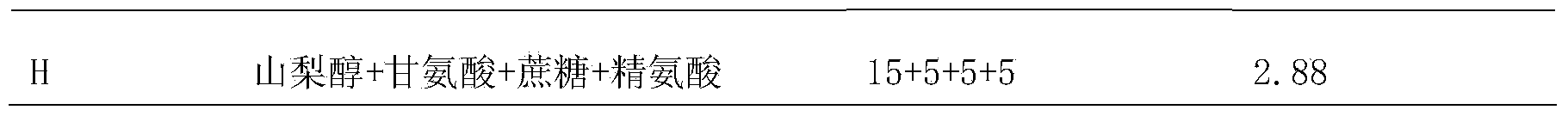

Method used

Image

Examples

Embodiment 1

[0045] A pasteurized inactivation method for intravenous injection of human immunoglobulin, comprising the following steps:

[0046] First, add protein protectant to the intravenous human immunoglobulin solution before inactivation, then adjust the protein content of the sample to 40g / L-60g / L, pH value 4.7-5.3, stir for 30 minutes, and put it in a water bath at 60°C±1°C When the temperature of the solution reaches 60°C, keep the solution temperature at 60°C±0.5°C for 10 hours to complete the inactivation of the intravenous injection of human immunoglobulin. The protein protectant includes 60g / L sucrose and 30g / L arginine L, glycine 40g / L and sorbitol 250g / L. After inactivation, take it out and measure the change of polymers before and after heating. The determination method is determined according to the "Chinese Pharmacopoeia" 2010 edition three appendix VI R "Human immunoglobulin products IgG monomer plus dimer determination method". The measured multimer change content was...

Embodiment 2

[0048] A pasteurized inactivation method for intravenous injection of human immunoglobulin, comprising the following steps:

[0049] First, add protein protectant to the intravenous human immunoglobulin solution before inactivation, then adjust the protein content of the sample to 40g / L-60g / L, pH value 4.7-5.3, stir for 30 minutes, and put it in a water bath at 60°C±1°C In the process, when the temperature of the solution reaches 60°C, keep the solution temperature at 60°C±0.5°C for 10 hours to complete the inactivation of the intravenous injection of human immunoglobulin. The protein protectant includes 70g / L sucrose, 20g / L arginine L, glycine 30g / L and sorbitol 260g / L. After inactivation, take it out and measure the change of polymers before and after heating. The determination method is determined according to the "Chinese Pharmacopoeia" 2010 Edition Three Appendix VI R "Human Immunoglobulin Products IgG Monomer Plus Dimer Determination Method"; The multimer change content...

Embodiment 3

[0051] A pasteurized inactivation method for intravenous injection of human immunoglobulin, comprising the following steps:

[0052]First, add protein protectant to the intravenous human immunoglobulin solution before inactivation, then adjust the protein content of the sample to 40g / L-60g / L, pH value 4.7-5.3, stir for 30 minutes, and put it in a water bath at 60°C±1°C In the process, when the temperature of the solution reaches 60°C, keep the solution temperature at 60°C±0.5°C for 10 hours to complete the inactivation of the intravenous injection of human immunoglobulin. L, glycine 20g / L 1 and sorbitol 240g / L. After inactivation, take it out and measure the change of polymers before and after heating. The determination method is determined according to the "Chinese Pharmacopoeia" 2010 Edition Three Appendix VI R "Human Immunoglobulin Products IgG Monomer Plus Dimer Determination Method"; The multimer change content was 1.98%, and the multimer change content before inactivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com