Cam bit die

A cam and mold technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems affecting product processing, air hole burrs, and mold filling dissatisfaction, so as to achieve smooth exhaust, Simple structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

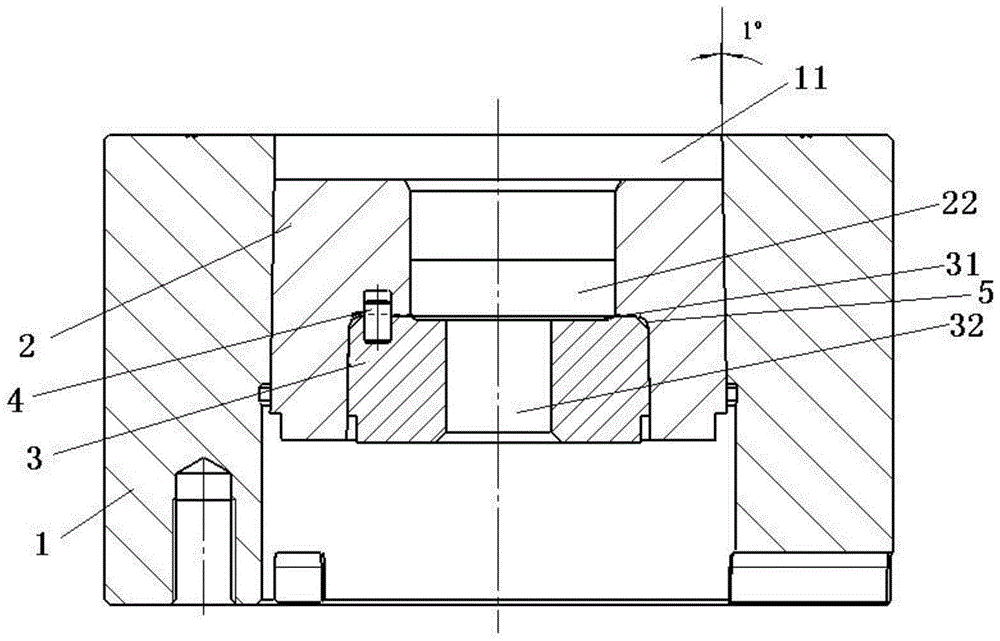

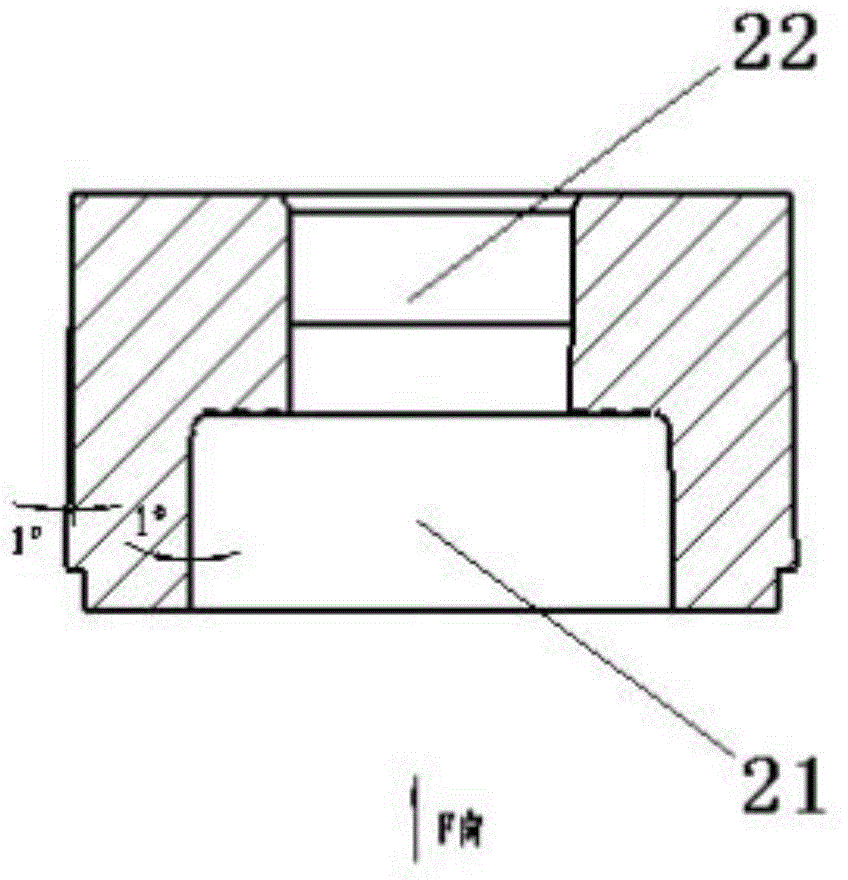

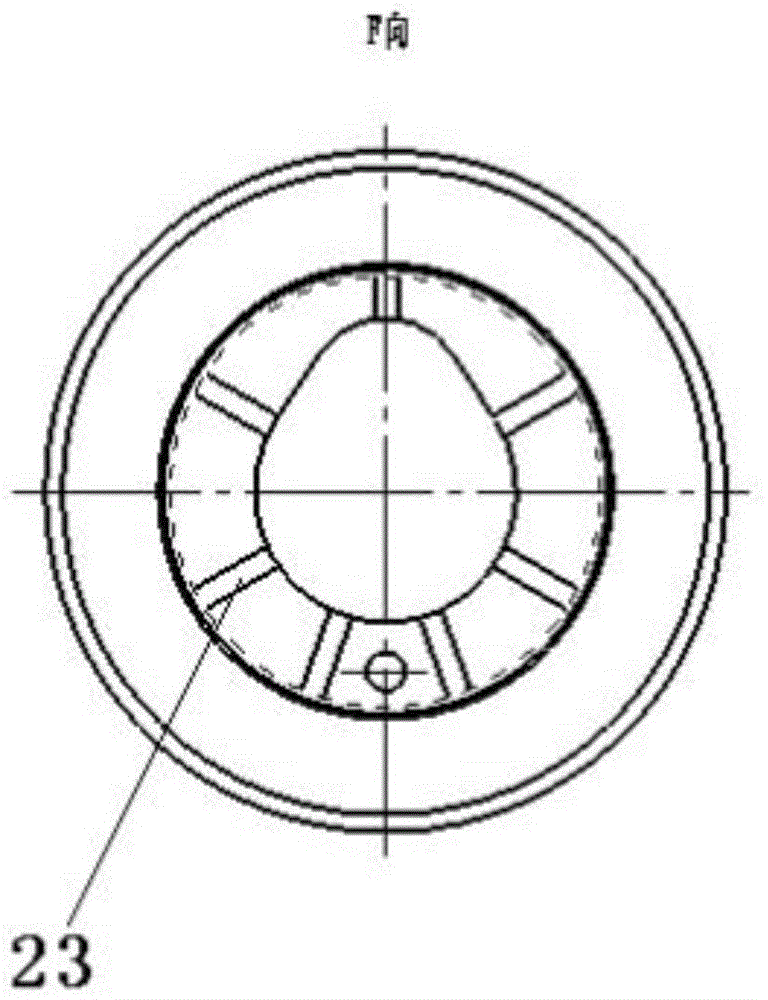

[0026] refer to figure 1 An assembly diagram showing an embodiment of the present invention, a cam block mold provided by the present invention includes a bottom die 1, an outer die 2 and an inner die 3, wherein the bottom die 1 is provided with an outer die 2 Compatible through hole 11, refer to figure 2 , the outer die 2 is provided with a groove 21 matched with the inner die 3, and the inner die 3 is connected with the outer die 2 through the groove 21, referring to figure 2 and image 3 , there is a mold entry angle of 1° between the inner die 3 and the outer die 2, and the H7 / m6 transition fit is used between the inner die 3 and the outer die 2, so that the inner die 3 can be connected with the outer die 2 The convenient assembly of the groove 21; the outer die 2 is connected with the bottom die 1 through the through hole 11 on the bottom die 1, and the H7 / z6 interference fit is adopted between the outer die 2 and the bottom die 1, so that The outer die 2 and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com