Robot gripper for box body stacking and unstacking

A robot hand and robot technology, which is applied in the direction of manipulator, stacking of objects, destacking of objects, etc., can solve the problems of skew, the accurate position and posture of the objects can not be well guaranteed, and the destacking operation cannot be performed. The effect of eliminating the possibility of unboxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following describes in detail the embodiment of the robot gripper used for palletizing and depalletizing boxes according to the present invention with reference to the accompanying drawings.

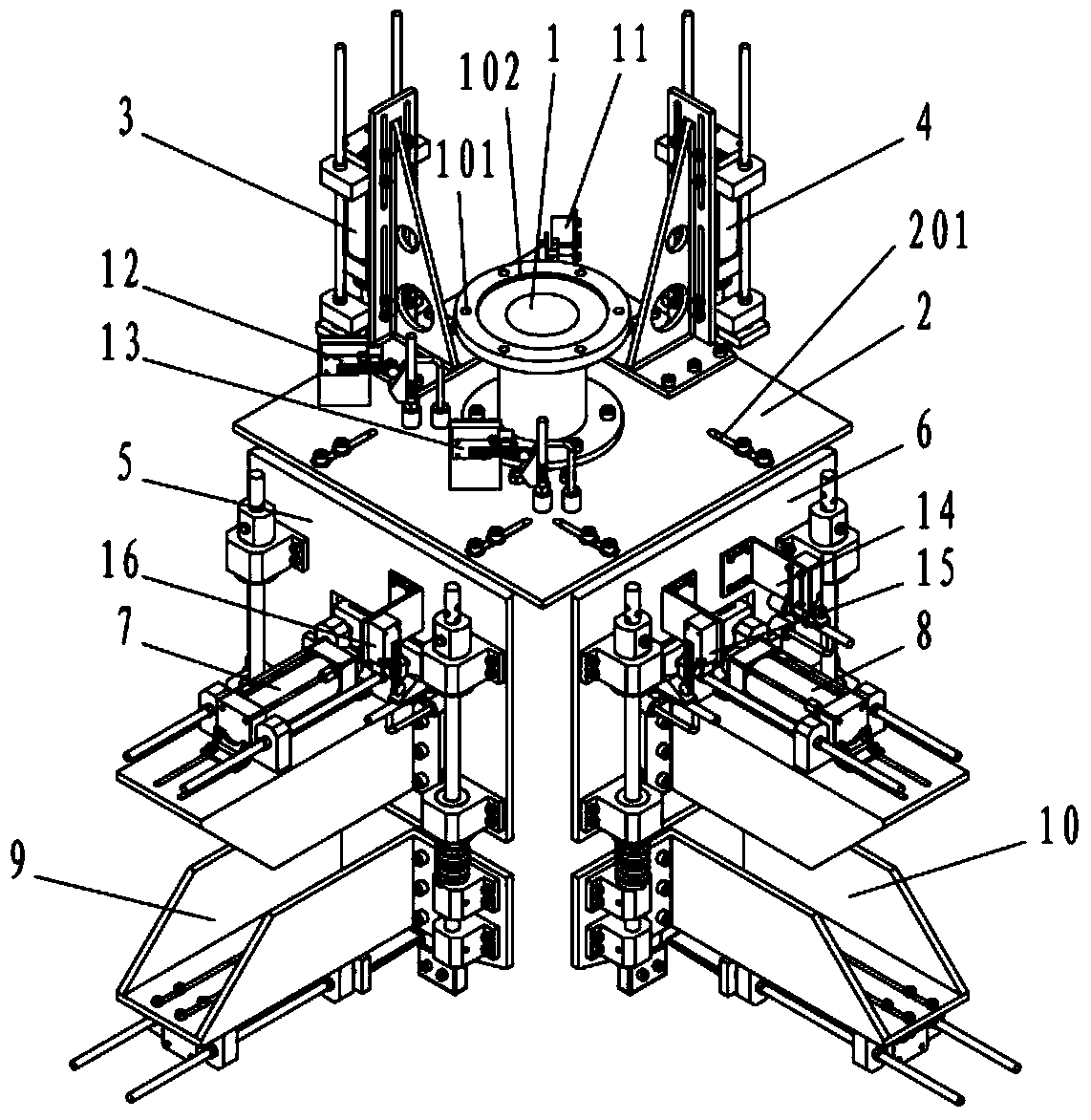

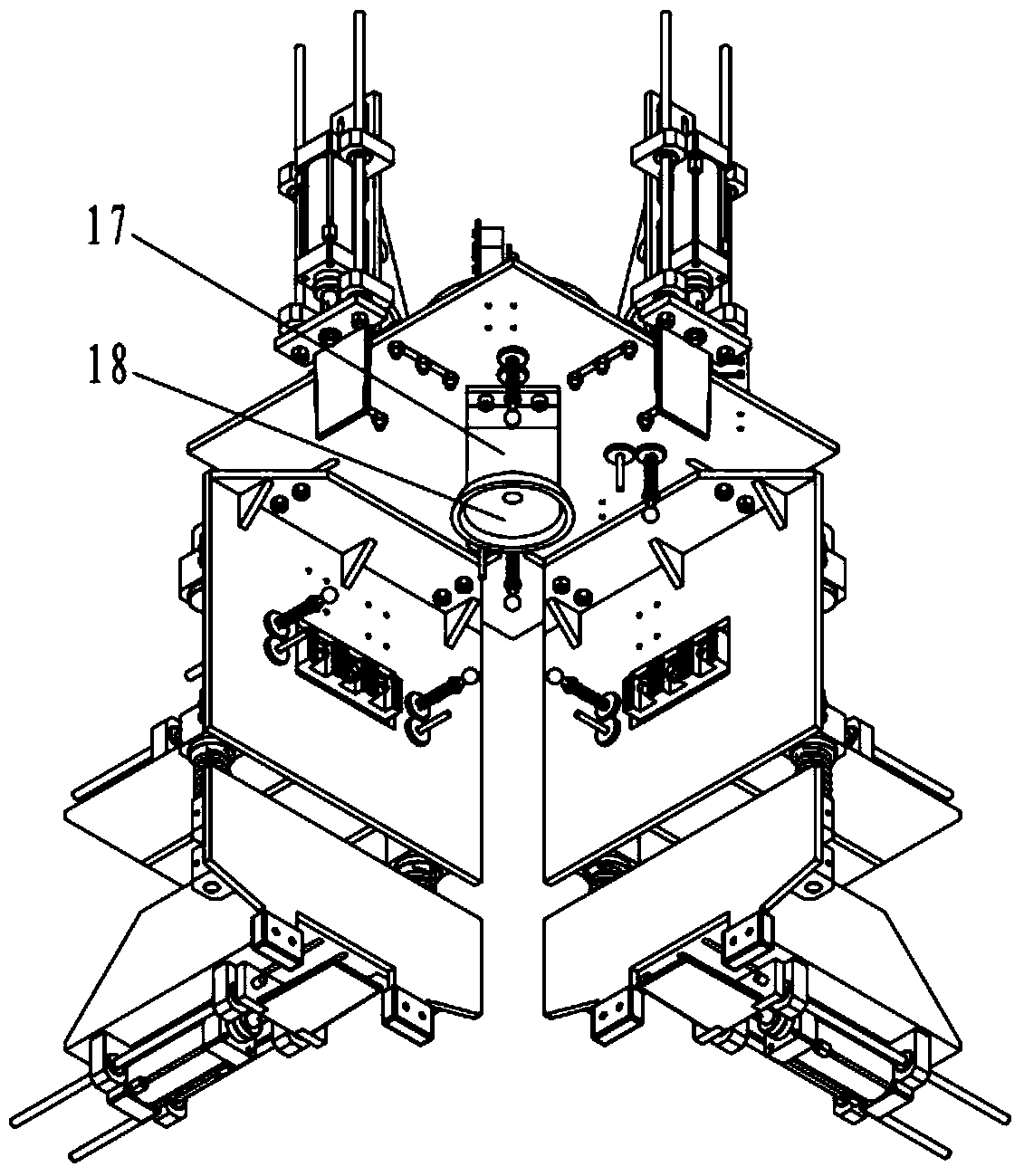

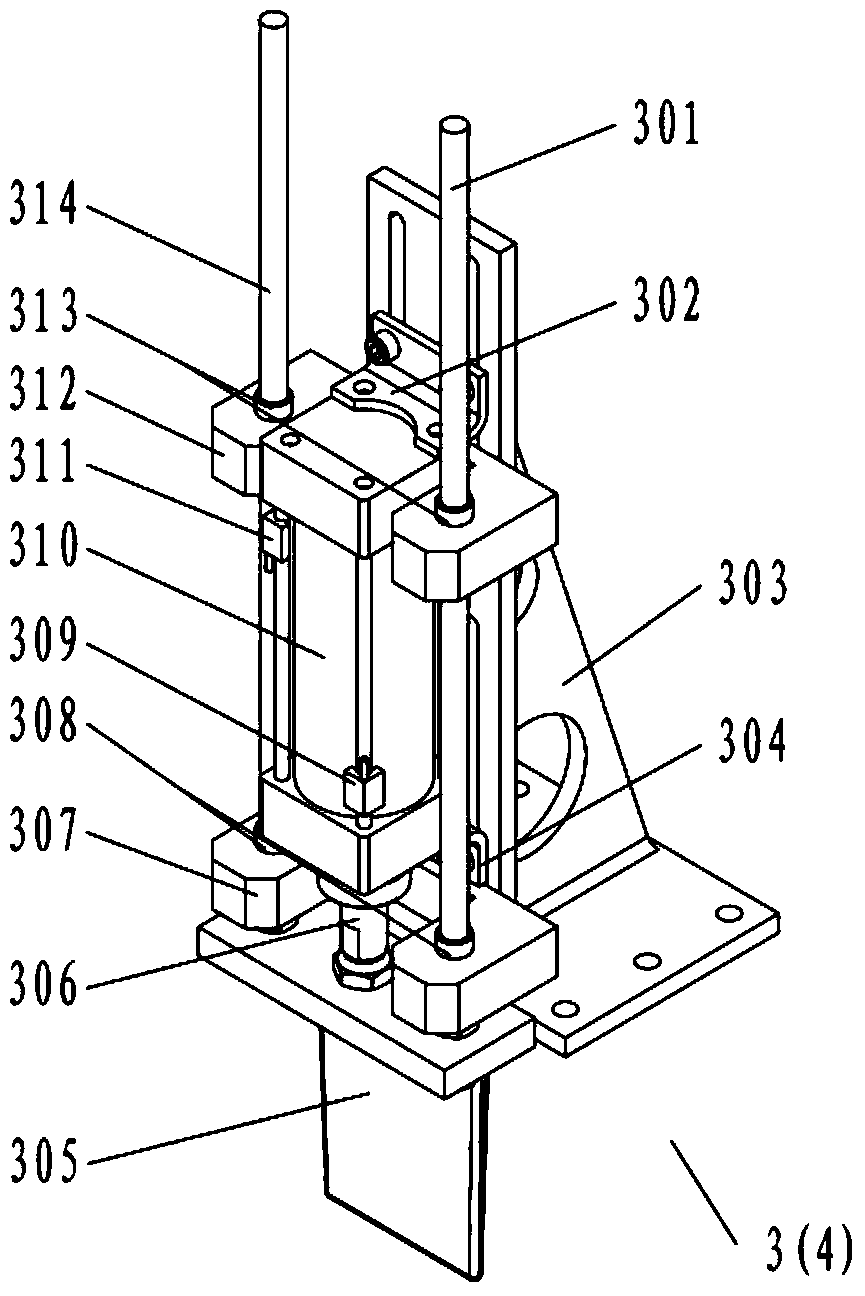

[0030] figure 1 and 2 , according to an embodiment of the present invention, the palletizing-depalletizing robot gripper includes: a flange plate 1, a top plate 2, a pair of insertion devices 3 and 4, a pair of side plate devices 5 and 6, a pair of lateral pressure Tightening devices 7 and 8, a pair of bottom side inserting devices 9 and 10, position sensor assemblies 11 to 16 respectively arranged on the top board and side boards, suction cup mounting bracket 17 and suction cup 18 installed under the top board.

[0031] The flange 1 is the mechanical interface for installing and connecting the palletizing-depalletizing robot's claws and the palletizing robot's wrist, and has notches 102 and bolt holes 101 on it. The top plate 2 is usually square, and is the installation bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com