Frequency converting control system of tower crane

A frequency conversion control and control system technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem that the advantages of high efficiency, safety and energy saving of frequency conversion controllers are not well reflected, the energy saving effect of frequency converter control systems is discounted, There are hidden dangers in the safe operation and reliability of equipment, and the effect of eliminating hidden dangers of permanent deformation, improving reliability and safety, and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

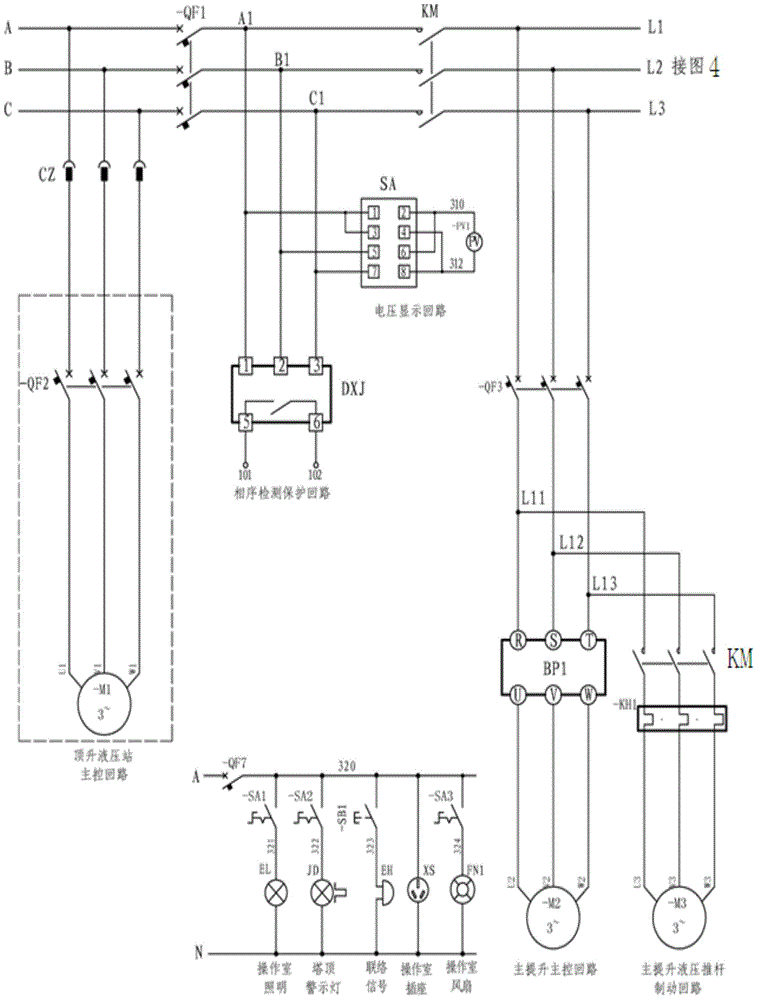

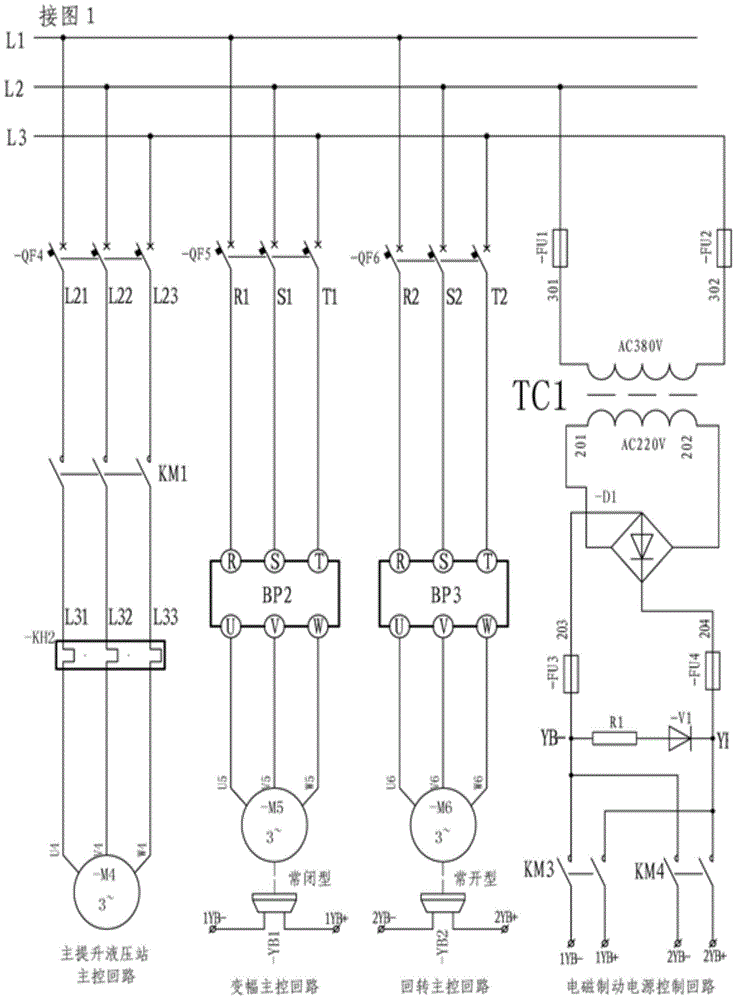

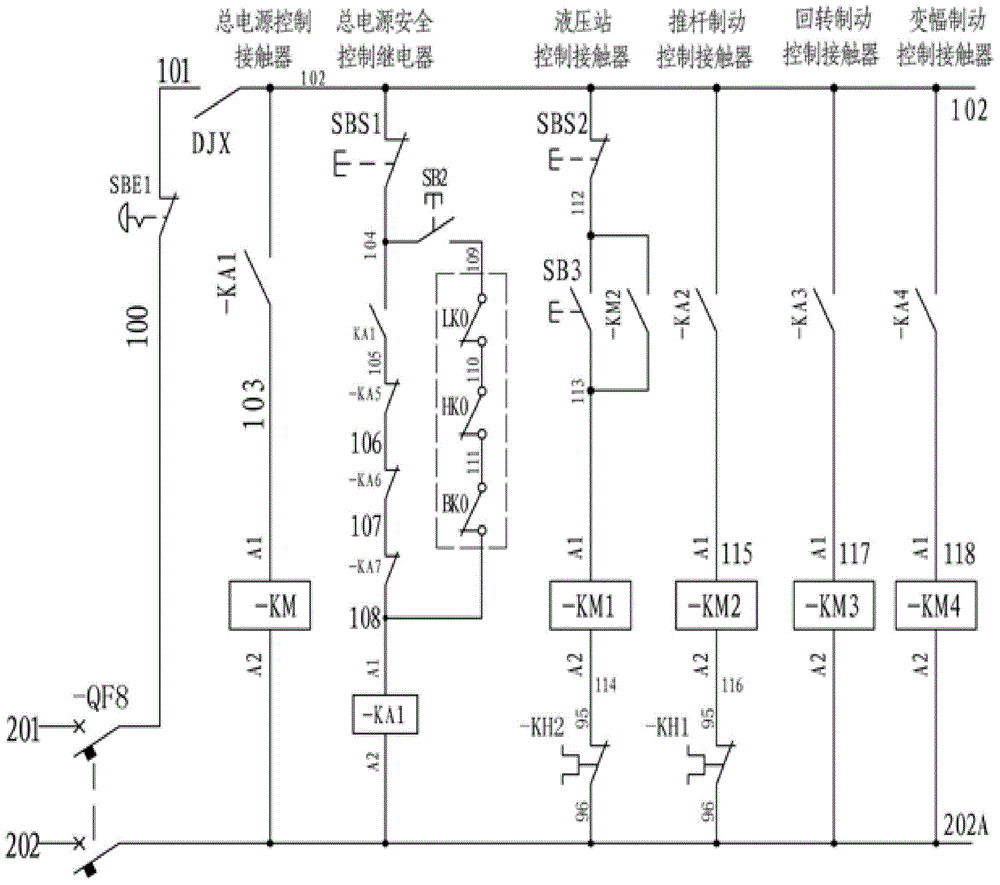

[0022] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 8 As shown, a tower crane frequency conversion control system includes a PLC control system 10 and a tower crane lifting frequency conversion control system 2. The tower crane variable amplitude and frequency conversion control system 4, the tower crane command control system 9, the tower crane braking system 11, the tower crane safety control system 12, the tower crane load and moment detection system 13 are connected, and the lifting drive system 5 is connected with the tower crane lifting frequency conversion control system 2 , the slewing drive system 6 is connected to the tower crane slewing frequency conversion control system 3, the variable amplitude drive system 7 is connected to the tower crane slewing frequency conversion control system 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com