A washing production line after printing and dyeing

A production line and water washing technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, liquid/gas/steam removal with squeeze rollers, etc., can solve the problem of lengthening the production line, cumbersome processing steps, high concentration of paste liquid, etc. problems, achieve low energy consumption, clean and environmentally friendly production, good dehydration and cleaning effects, and lengthen the walking path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

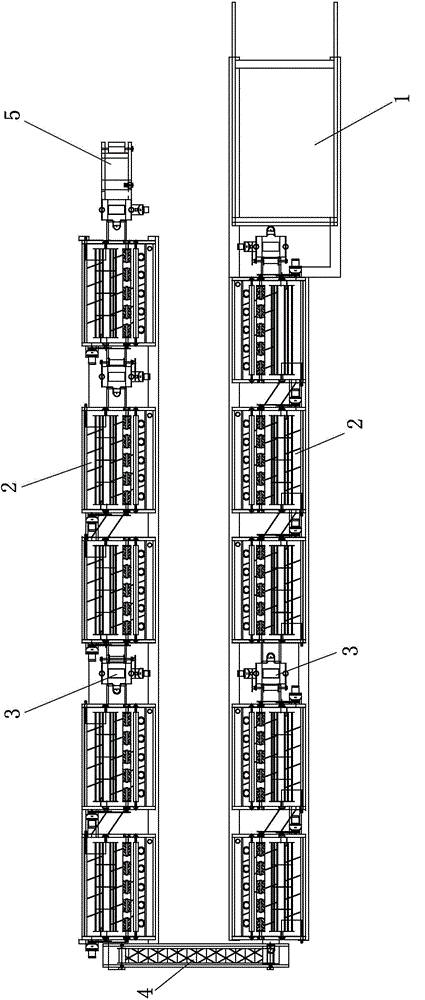

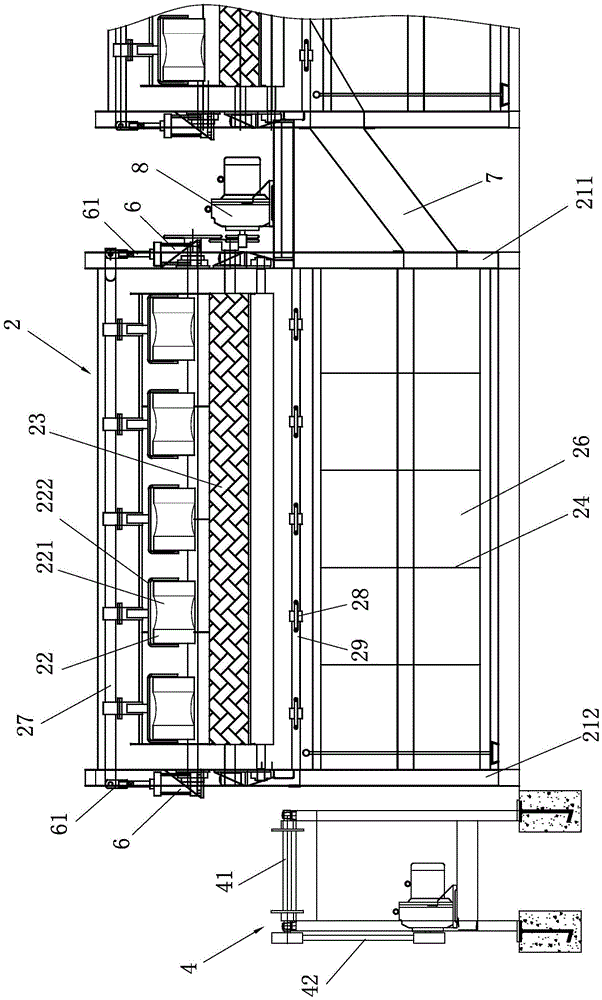

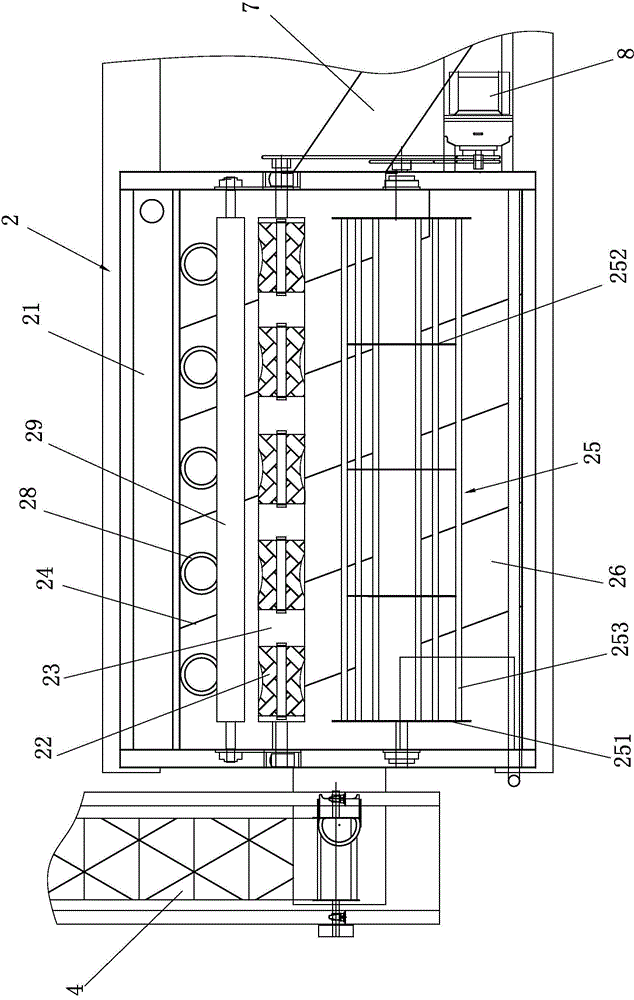

[0021] Such as Figure 1 to Figure 5 As shown, a washing production line after printing and dyeing includes a washing unit 2 arranged on the production line, a water squeezing device 3 between boxes, and a cloth inlet device 1 and a cloth outlet device 5 respectively arranged at the head and tail of the production line. U" shape, two parallel longitudinal production lines are connected by a horizontal turning guide belt 4 at one end, the turning guide belt 4 is installed on the drum 41, and the drum 41 is driven by a transmission device 42, and the turning guide belt 4 connects the washing water unit 2 on the upstream side The discharge port is connected to the feed port of the washing water unit 2 on the downstream side, and an inter-tank water squeezing device 3 is arranged between some washing water units 2 . The other ends of the two par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com