Energy-saving emission-reducing particle washing and water extracting machine

A technology for energy saving, emission reduction and washing machine, which is applied to other washing machines, washing machines with containers, control devices of washing machines, etc. High efficiency, energy saving and environmental protection obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The energy-saving and emission-reducing particulate washing machine of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

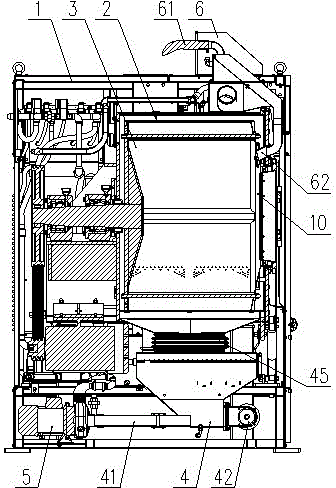

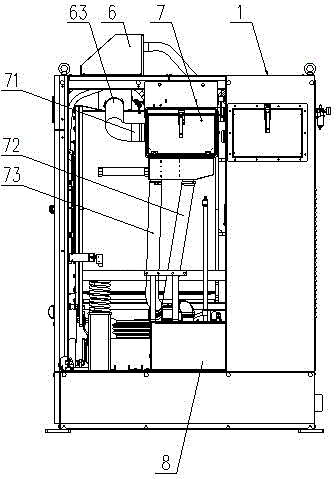

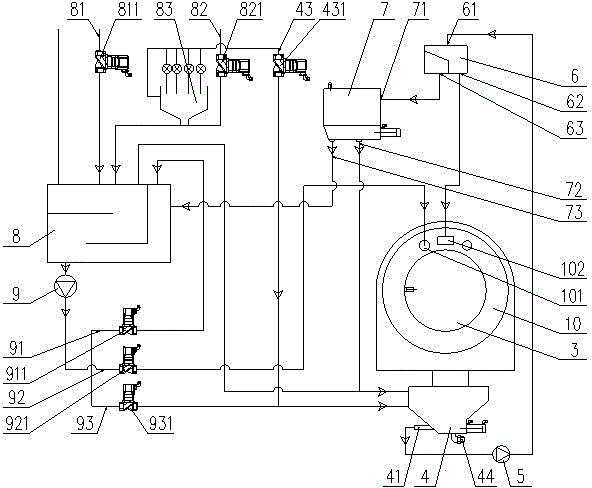

[0023] see figure 1 , figure 2 , image 3 As shown, the energy-saving and emission-reducing particulate washing machine of the present invention includes: a casing assembly 1, a barrel assembly 2 arranged in the casing, a drum 3 arranged in the barrel, and a drive assembly for driving the rotation of the drum 3 , and the control assembly for controlling the work of the washing machine. On the barrel before the feed port of the drum 3, an annular end cover 10 that can prevent the linen from falling out is provided. On the end cover 10, there is a water and The particles are sprayed into the water injection holes 101 and the particle injection holes 102 in the drum 3 respectively, and a particle suspension turbulator installed on the bottom of the casing is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com