Construction method for underwater non-dispersible cement-based self-compaction material

A construction method and dense technology, applied in infrastructure engineering, construction, etc., can solve the problems of high pollution and high cost, achieve high flow performance, improve success rate, and improve adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

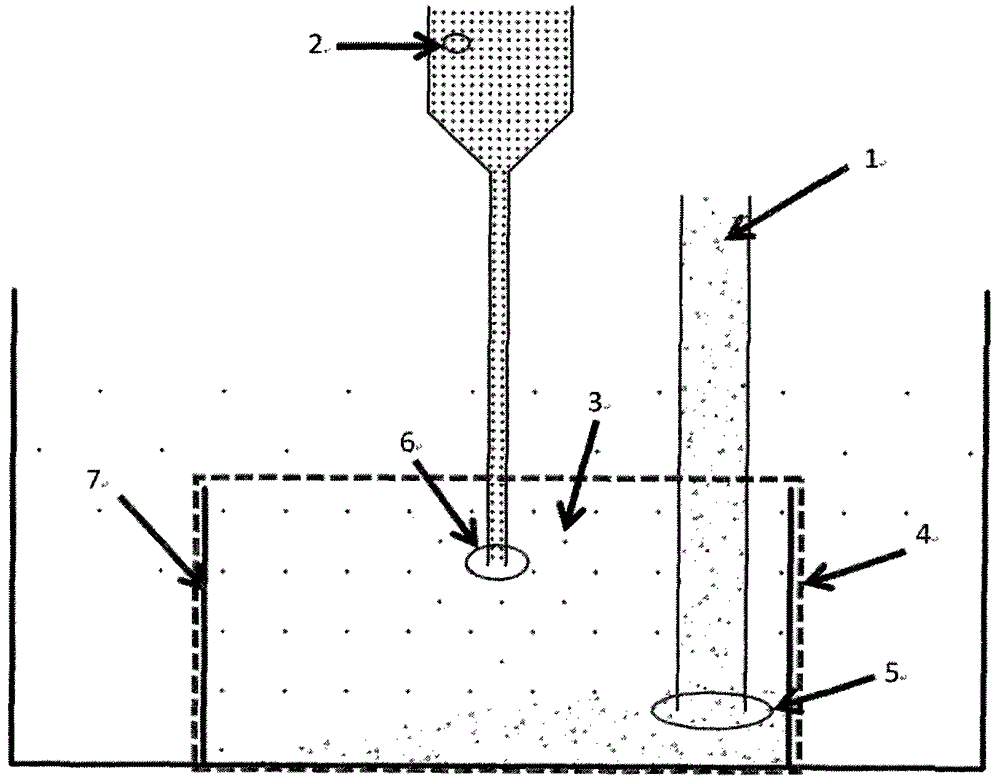

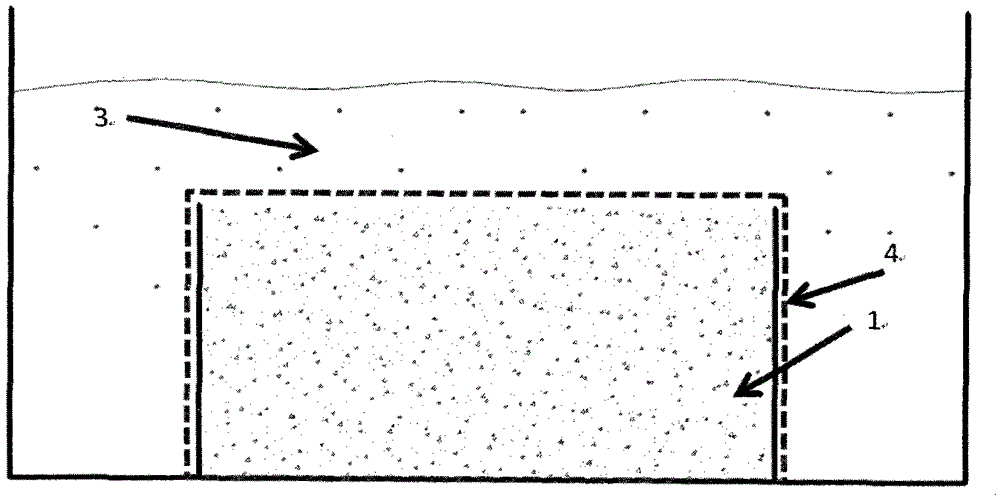

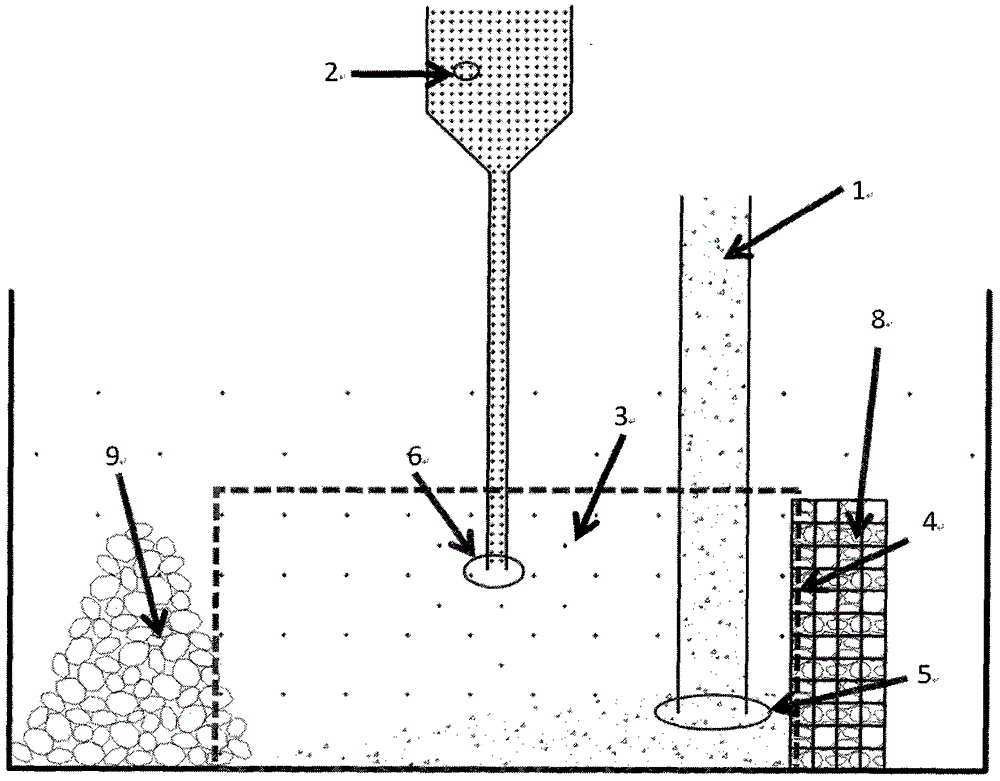

[0028] Combine below Figure 1 to Figure 6 , the present invention is further described:

[0029] (1) Formwork 7 is provided for the underwater parts that need to be poured, and there is no need to provide formwork for parts with natural barriers or existing barriers. For underwater structures and structures, there are usually specific shape requirements, and formwork 7 should be set on the outer boundary of the structure. When the shape of the outer boundary of structures and structures is not high, steel gabion 8 or riprap accumulation can be used 9 Set barriers. For the underwater part of the underwater seepage channel and foundation fissure, the formwork cannot be set, and the filling range can be controlled by controlling the flow distance of the concrete material.

[0030] (2) Determine the positions of the cement-based self-compacting material pouring point 5 and the water-soluble polymer solution pouring point 6 according to the underwater parts to be poured. The pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com