Connecting rod structure for piston

A technology of piston connecting rod and connecting rod, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of friction pair corrosion, high crankcase pressure, oil dilution, etc., and achieve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

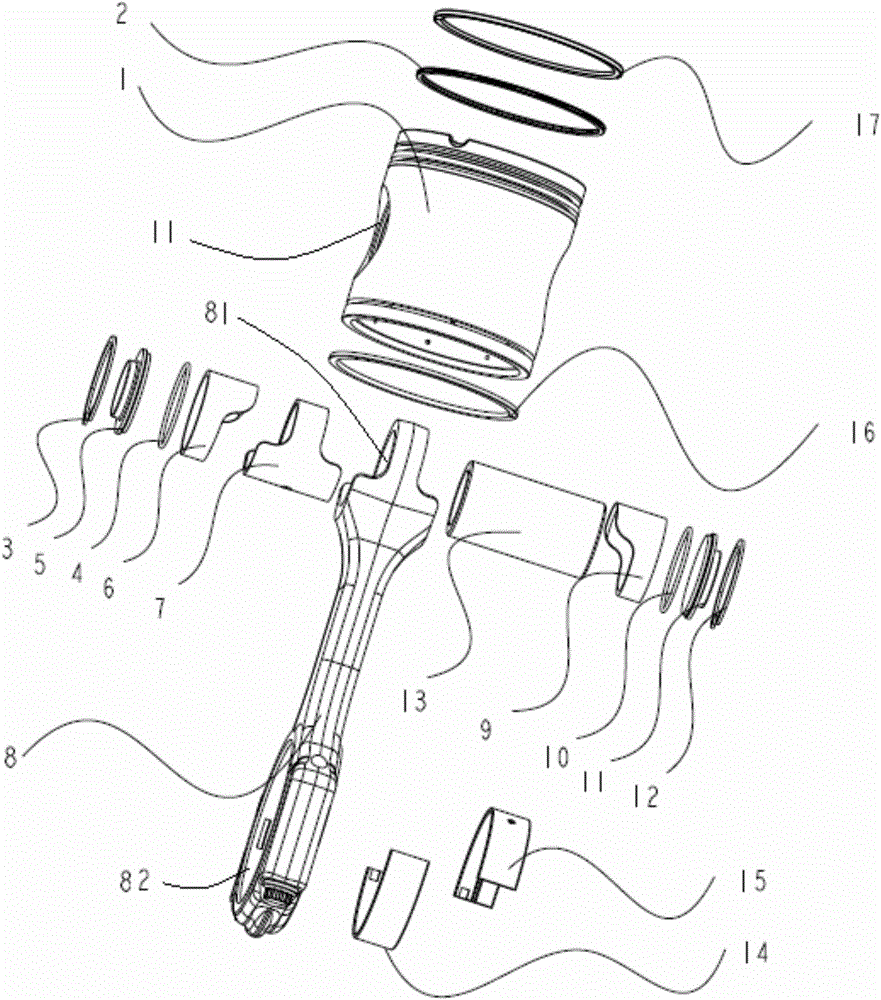

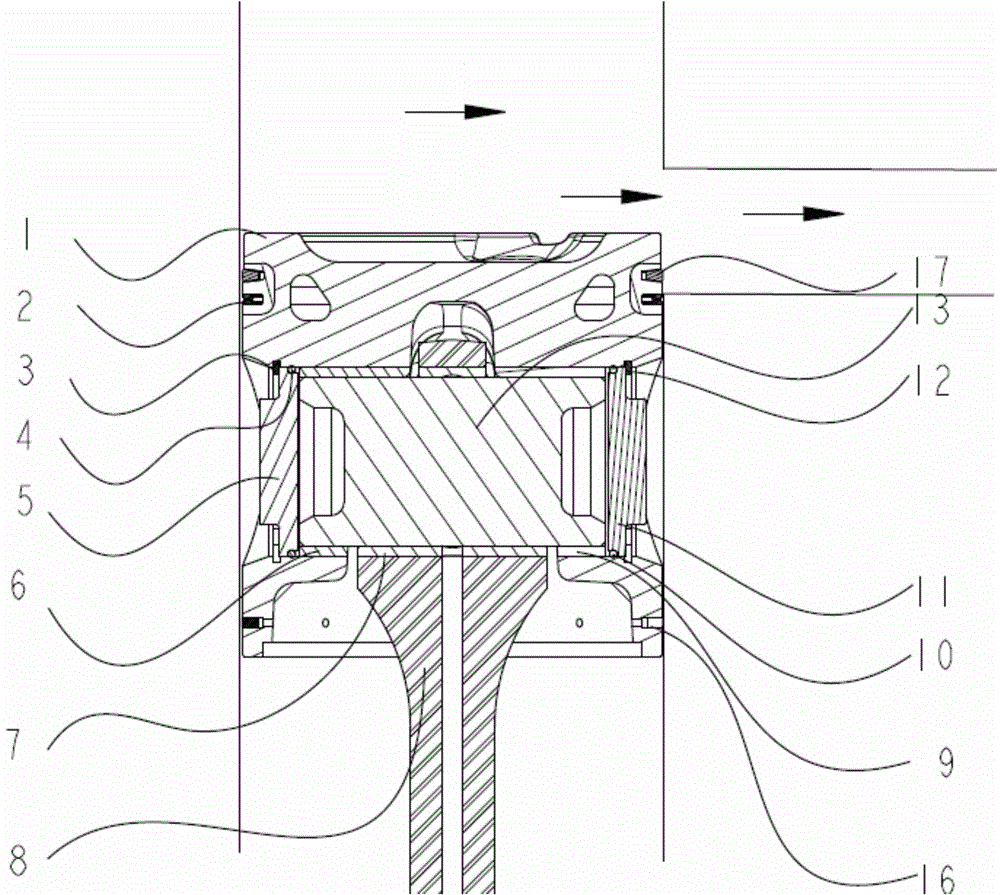

[0022] In further embodiments of the present invention, please continue to refer to figure 1 shown. A gas ring groove is opened around the upper end of the piston 1, and a gas ring 17 is installed in the gas ring groove. A gas ring groove is opened around the lower two ends of the piston 1, and a gas ring 16 is installed in the gas ring groove.

[0023] In a further embodiment of the present invention, an oil ring groove is opened around the upper end of the piston 1 , and an oil ring 2 is installed in the oil ring groove.

[0024] In a further embodiment of the present invention, the opening position of the oil ring groove is lower than the opening position of the gas ring groove at the upper end of the piston 1 .

[0025] In a further embodiment of the present invention, a retaining ring 3 is sleeved on the outside of the piston pin cover 5 , and a spring retaining ring 12 is sleeved on the outside of the piston pin cover 11 . Annular grooves are provided in the two conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com