Fiber Bragg Grating Sensing Wavelength Calibration Device Based on Cavity Absorption

A fiber grating and calibration device technology, applied in the direction of instruments, etc., can solve the problems of drift and the lack of attention to the calibration method, and achieve the effect of simplifying the calibration system and improving the measurement accuracy and measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

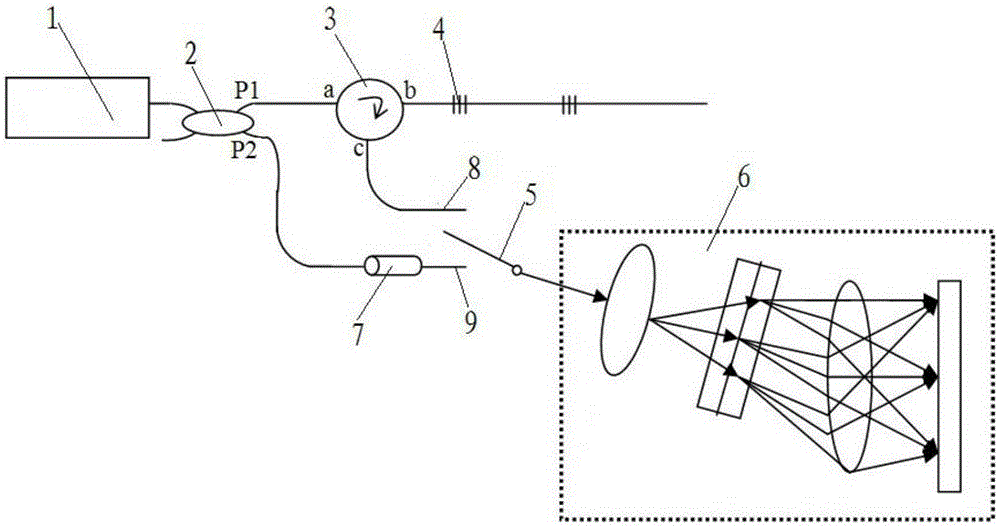

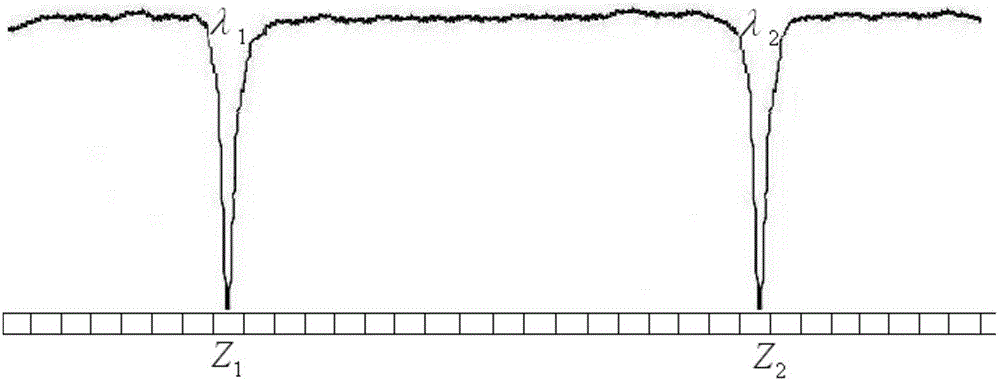

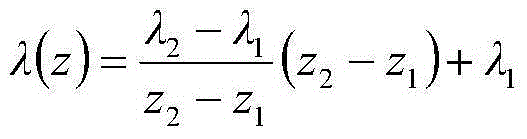

[0014] The present invention adopts figure 1 In the design of the demodulation system shown, the gas absorption layer can choose different gases according to the actual situation, such as acetylene, CO, etc. The design of the fiber grating sensing system includes two optical paths. The system is provided with broadband light by the ASE light source 1 (1525nm-1610nm), which is divided into two beams by the coupler 2: the broadband light output from the P1 port enters the a port of the optical circulator 3 , and then enter the grating array 4 through the b port, and the reflected sensing spectrum reaches the optical switch connection terminal I8 through the c port; the broadband light output from the P2 port enters the low reflectivity resonant cavity 7, which is filled with light in the near-infrared region. Two gases with obvious absorption peaks and known peak wavelengths make the two characteristic spectra fully absorbed, and a reflection spectrum with high-precision absorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com