Mobile detection device for refueling machine

A technology for verification devices and fuel dispensers, applied in measuring devices, testing/calibrating devices, instruments, etc., can solve problems such as narrow space in the compartment, dim light, liquid overflow, etc., achieve high-tech advancement, improve accuracy and stability , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

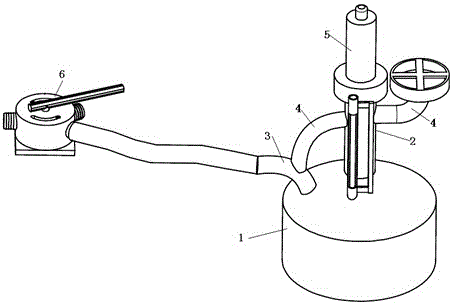

[0026] Such as Figure 2 to Figure 6 As shown, the fuel dispenser mobile verification device of the present invention includes a standard metal gauge 1, a fuel delivery pipeline 3, a three-way switching valve 6, and a measurement system.

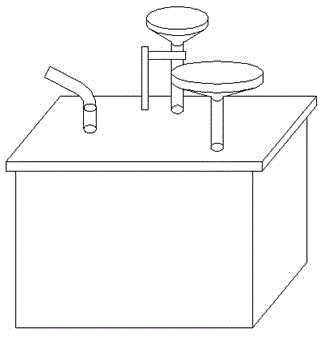

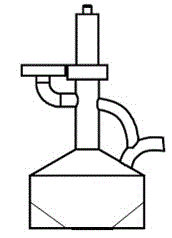

[0027] Such as image 3 As shown, the standard metal gauge 1 is composed of an inner and outer tank of a metal container, and the inner tank of the metal container is composed of two upper and lower cones and a cylinder. The standard metal gauge 1 is provided with a fuel delivery pipe 3 and a metering neck 2 . The present invention changes the original square container structure into a circular structure (see figure 1 ), designed and manufactured with reference to the technical requirements of standard metal measuring instruments, and the upper and lower sides are designed as cones, which completely eliminates the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com