Radiographic inspection method with medium high-temperature pipeline

A technology of ray detection and pipeline, which is applied in the direction of material analysis using radiation, etc., can solve the problems that the ray source cannot be used in conjunction with industrial radiography film, and useful images cannot be obtained, so as to achieve reliable technical support and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

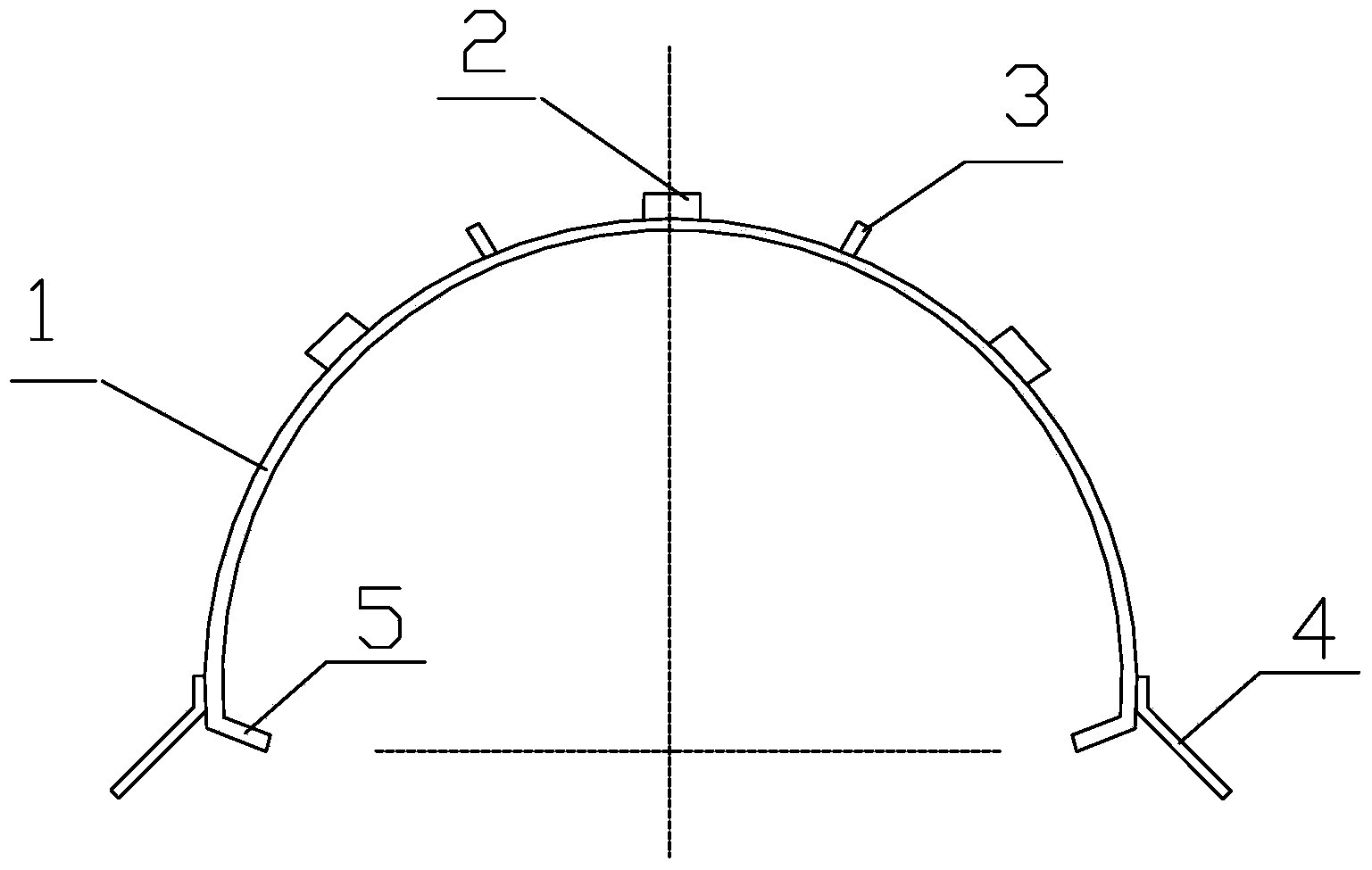

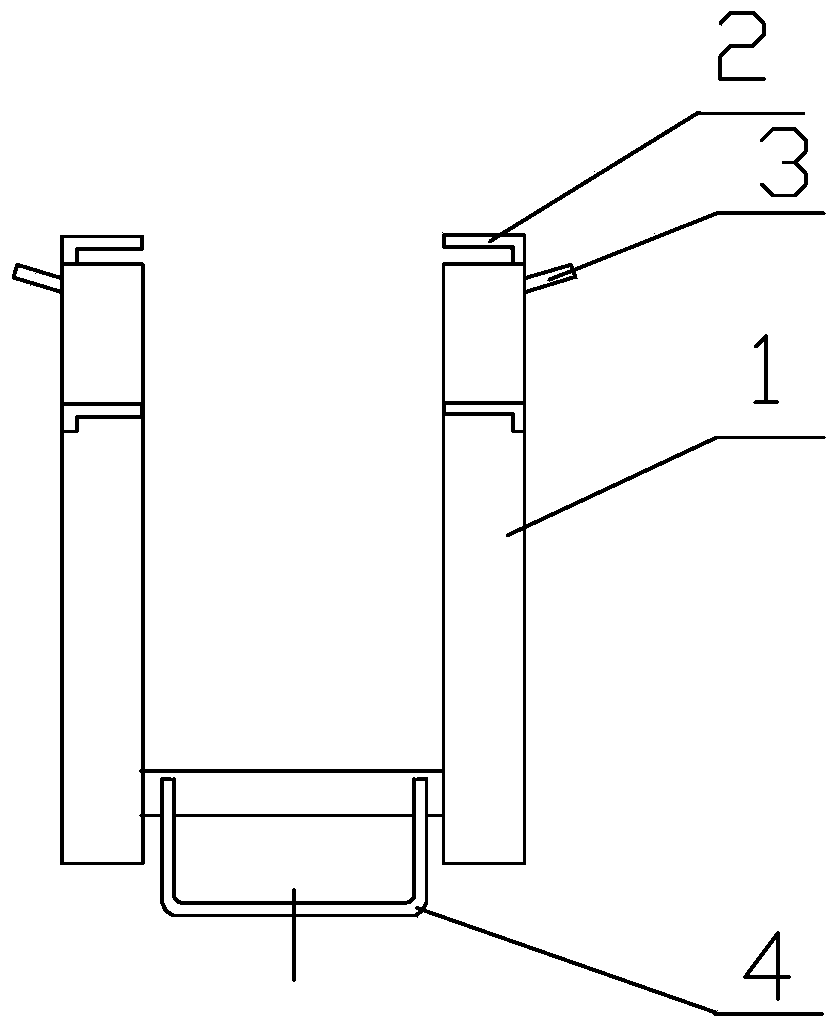

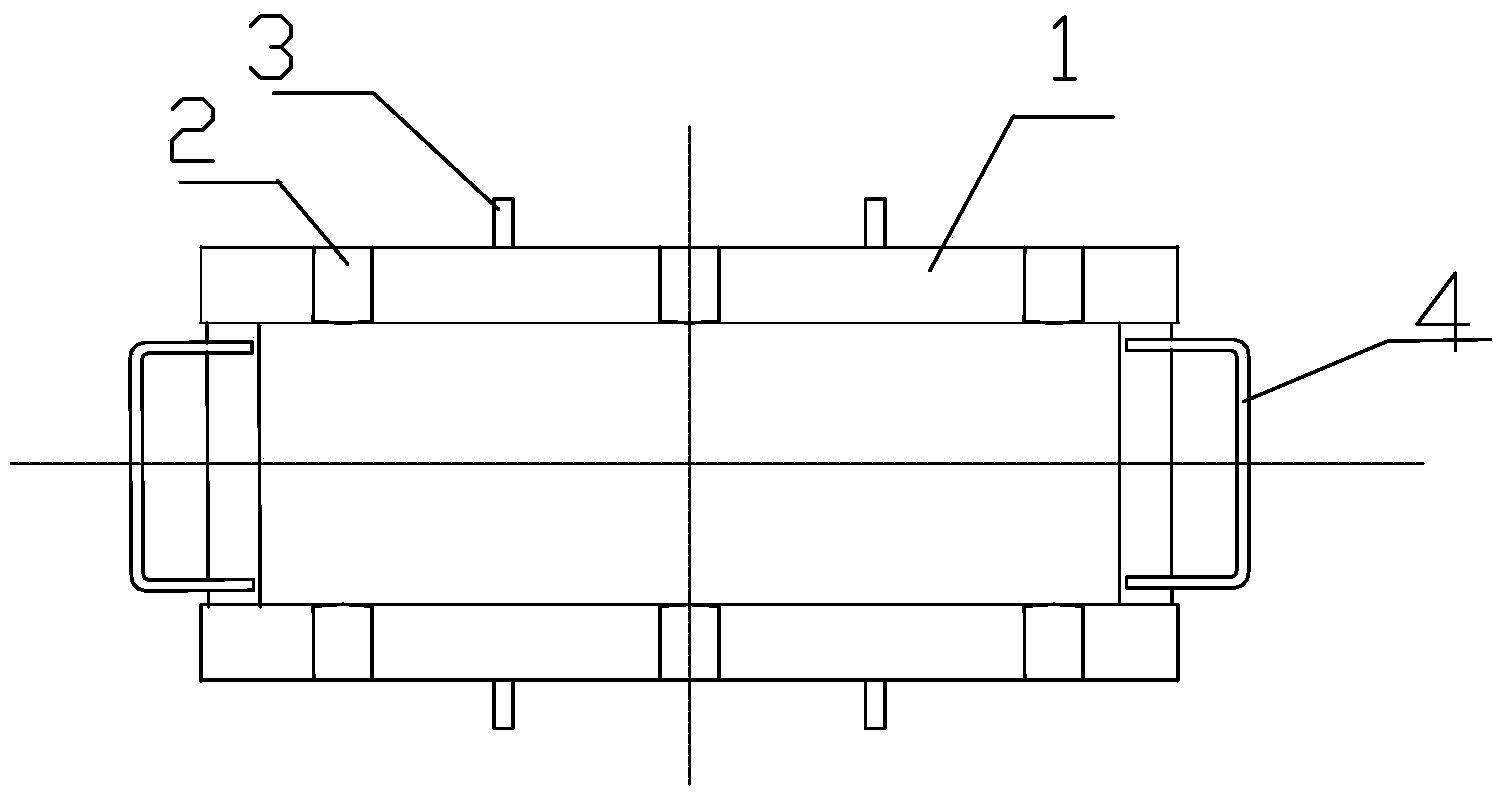

[0024] The radiographic detection method of the high-temperature pipeline with medium of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

[0025] The radiation detection method of the high-temperature pipeline with a medium of the present invention adopts the heat insulation layer to insulate the film, selects the thin heat insulation layer; attaches the tooling through the film and the heat insulation layer; selects the appropriate detection process parameters such as tube voltage and exposure time , Add lead plates to prevent back scattering, so that high-pressure and high-temperature pipelines with medium radiography can meet sufficient negative film quality or blackness requirements.

[0026] Radiographic inspection of pipelines for liquid or gaseous media, in order to meet the requirements of sufficient film quality or blackness, effectively detect defects, and identify and quantify defects. One is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com