Wireless postback system of production data of bulk cargo loading and unloading equipment

A technology for production data and bulk cargo loading and unloading, which is applied in data processing applications, logistics, computing, etc., and can solve problems such as status information cannot be counted, data analysis and management is difficult, and information volume is insufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

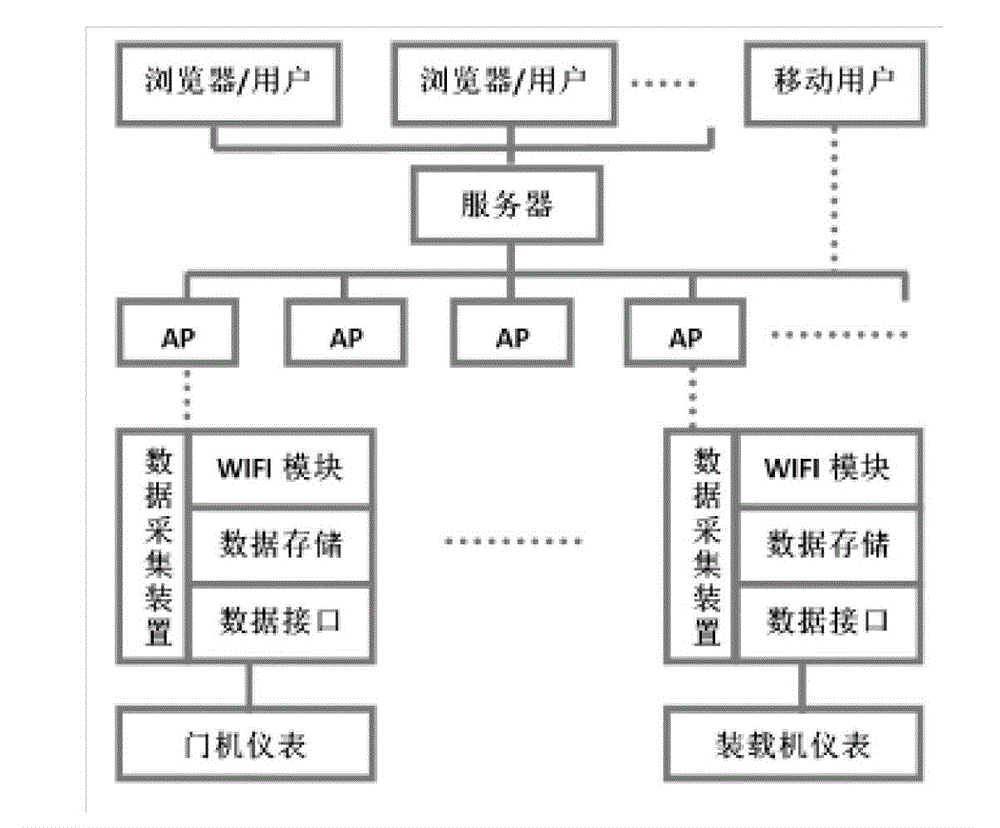

[0029] Such as figure 1 , 2 As shown in a bulk cargo handling equipment production data wireless return system, the server is connected to multiple user browsers, multiple mobile users, multiple wired and wireless network bridge APs; each AP is connected to the data acquisition device, each A data acquisition device is connected to the instrumentation of the equipment on the wharf: portal machine instrumentation, loader instrumentation.

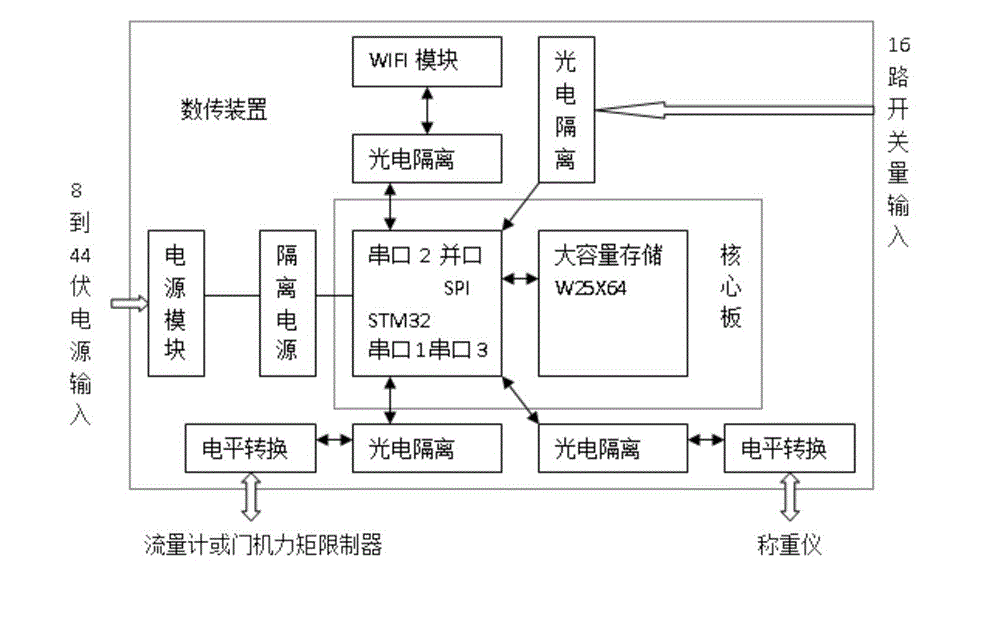

[0030] Described data collection device has core board, and there are large-capacity memory, serial port, parallel port on core board, and large-capacity memory connects these serial ports and parallel port; circuit switch, WIR module and multiple level shifters; the level shifter modules are respectively connected to flowmeters, electric energy meters, door machine torque limiters and weighing instruments.

[0031] Bulk cargo handling equipment production data wireless return system:

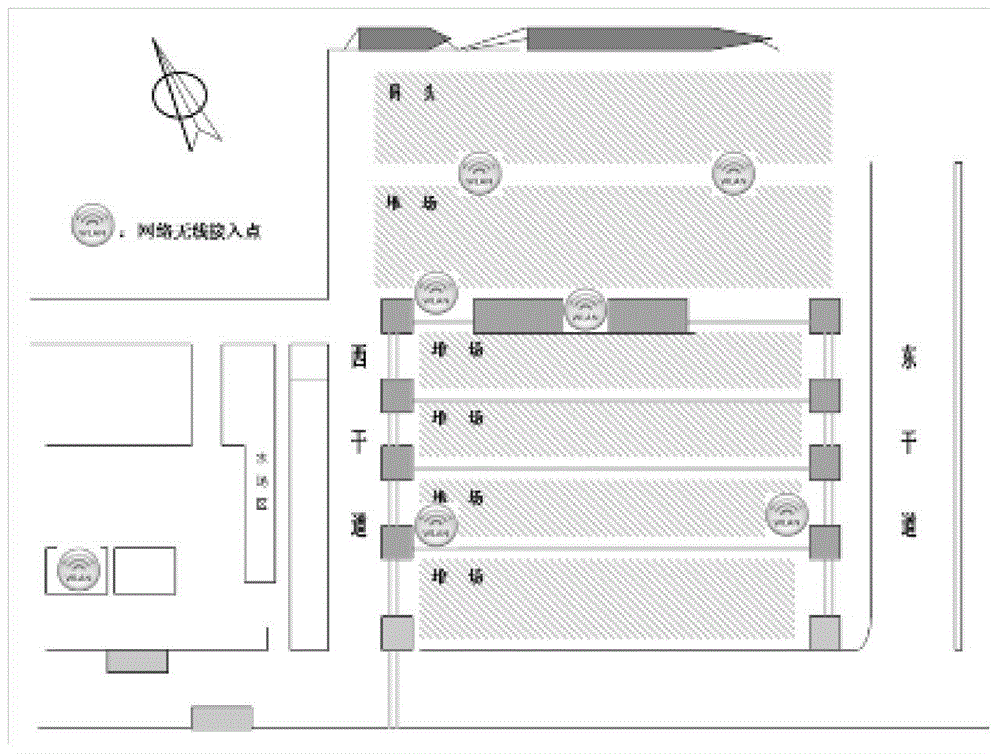

[0032] Install data acquisition and return devices on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com