Movable discharge electrode applied to capillary tube discharge soft X-ray lasers

A discharge electrode and capillary technology, applied in the direction of circuits, electrical components, phonon exciters, etc., can solve problems such as inconsistencies in current waveforms, and achieve accurate laser gain coefficients and accurate measurement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

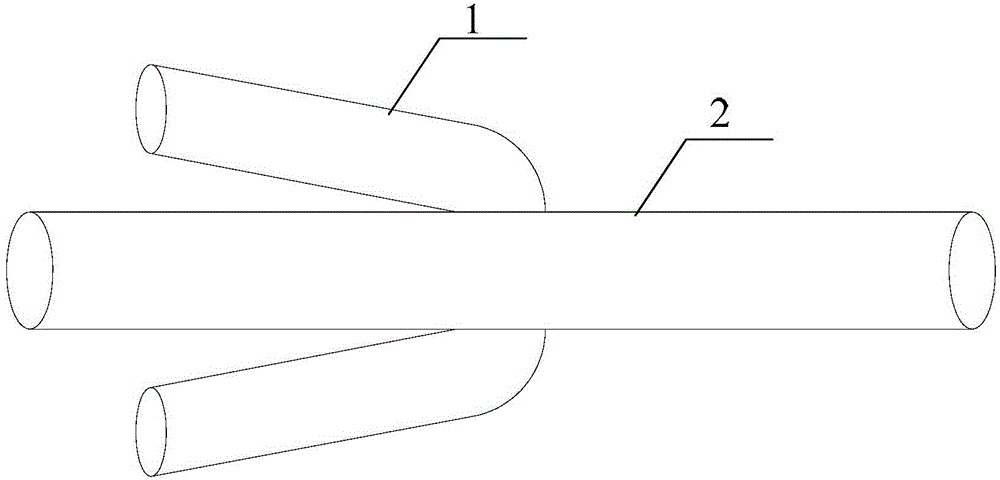

[0018] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the movable discharge electrode used in the capillary discharge soft X-ray laser described in this embodiment, which includes: a steel wire 1 and an electrode 2;

[0019] There is a through hole on the electrode 2, the diameter of the through hole is the same as the outer diameter of the steel wire 1, the steel wire 1 passes through the through hole and is fixed on the electrode 2, and the steel wire 1 is perpendicular to the electrode 2, and both ends of the steel wire 1 are bent at the same time to one end of electrode 2;

[0020] The outer diameter of the steel wire 1 is smaller than that of the electrode 2; the average tension of the steel wire 1 is between 88kg and 92kg, and the outer diameter of the steel wire 1 is between 0.8mm and 1.2mm.

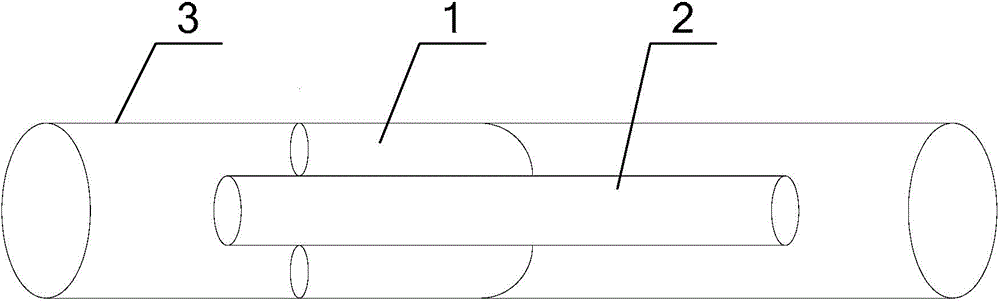

[0021] The inner diameter of the capillary 3 is between 8.0 and 3.0 mm, the most common inner diameter being 3.2 mm. The inner diamete...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment further describes the movable discharge electrode used in the capillary discharge soft X-ray laser described in Embodiment 1. In this embodiment, the electrode 2 is a molybdenum electrode. Embodiment 3: This embodiment further describes the movable discharge electrode used in the capillary discharge soft X-ray laser described in Embodiment 1 or 2. In this embodiment, the length of the electrode 2 is 10 mm.

specific Embodiment approach 4

[0023] Embodiment 4: This embodiment further describes the movable discharge electrode used in the capillary discharge soft X-ray laser described in Embodiment 1 or 2. In this embodiment, the outer diameter of the steel wire 1 is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com