Container volume control unit at upstream of filling level control unit

A technology for filling liquids and containers, which is used in the safety devices of filling devices, liquid handling, liquid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

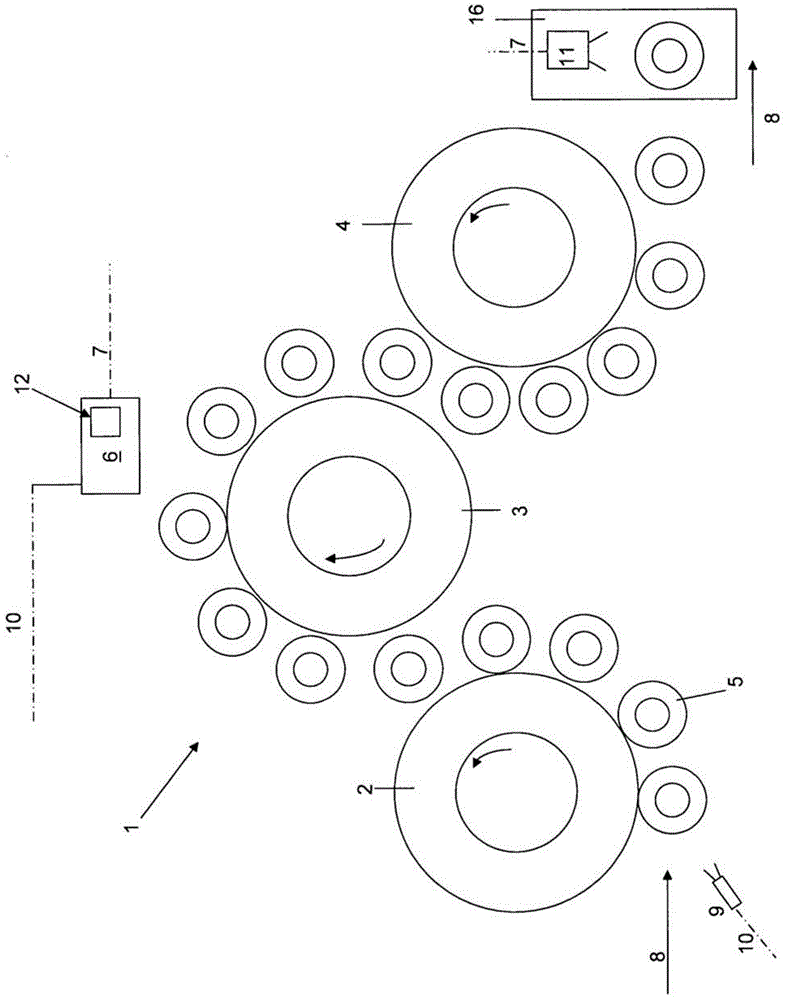

[0033] figure 1 The container processing device 1 in the embodiment is shown as an exemplary rotary filling machine 1, according to which the present invention should not be limited to a rotary type but of course can also be set as a linear processing machine and / or along a linear conveying path .

[0034] The filling machine 1 has a feeding star wheel 2, a main star wheel 3 and a discharging star wheel 4. figure 1 The ratio or size of the middle feeding star wheel 2 and the discharging star wheel 4 relative to the main star wheel 3 is of course not proportional. In fact, the main star wheel 3 of course has a larger diameter (for example, 6 m) than the diameter (for example, 1.5 m) of the supply star wheel 2 and the discharge star wheel 4.

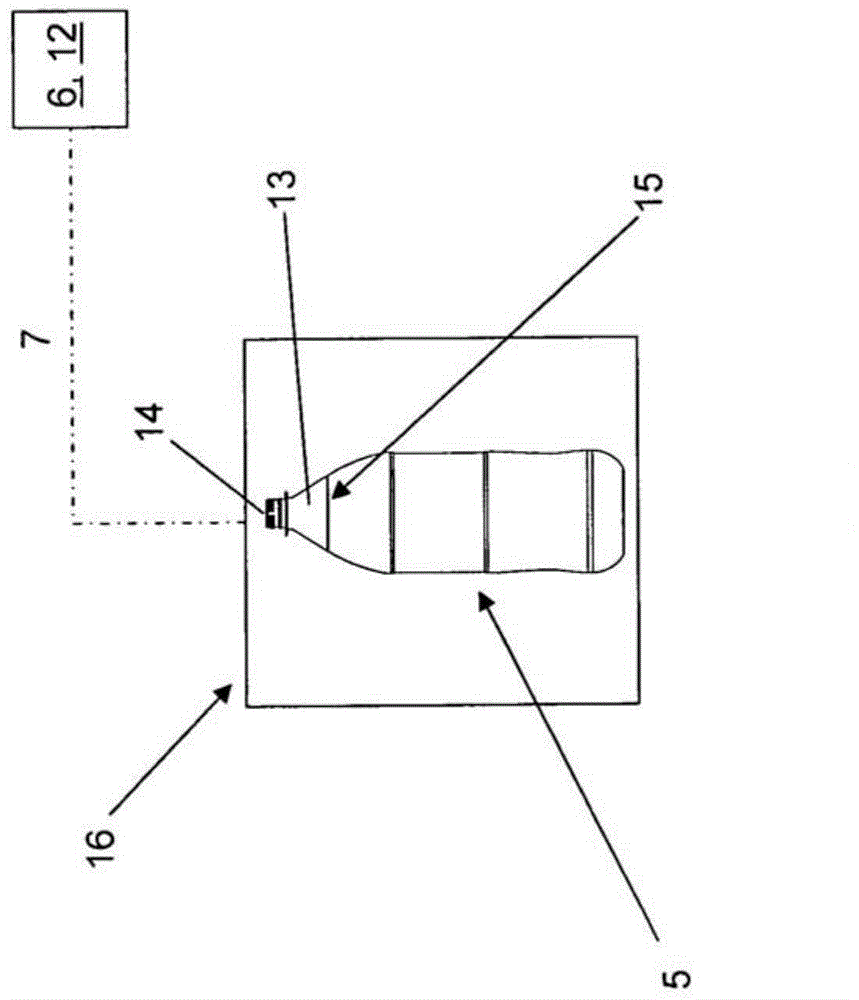

[0035] The main star wheel 3 is provided with a filling element, which fills the container 5 with products. A filling level monitor is installed downstream of the discharging star wheel 4. figure 1 Only the camera 11 of the filling level monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com