Polishing composition and polishing method

A composition and compound technology, applied in polishing compositions containing abrasives, chemical instruments and methods, grinding devices, etc., can solve problems such as technical difficulties and no specific disclosure of technical solutions, and achieve the effect of less changes over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~5)

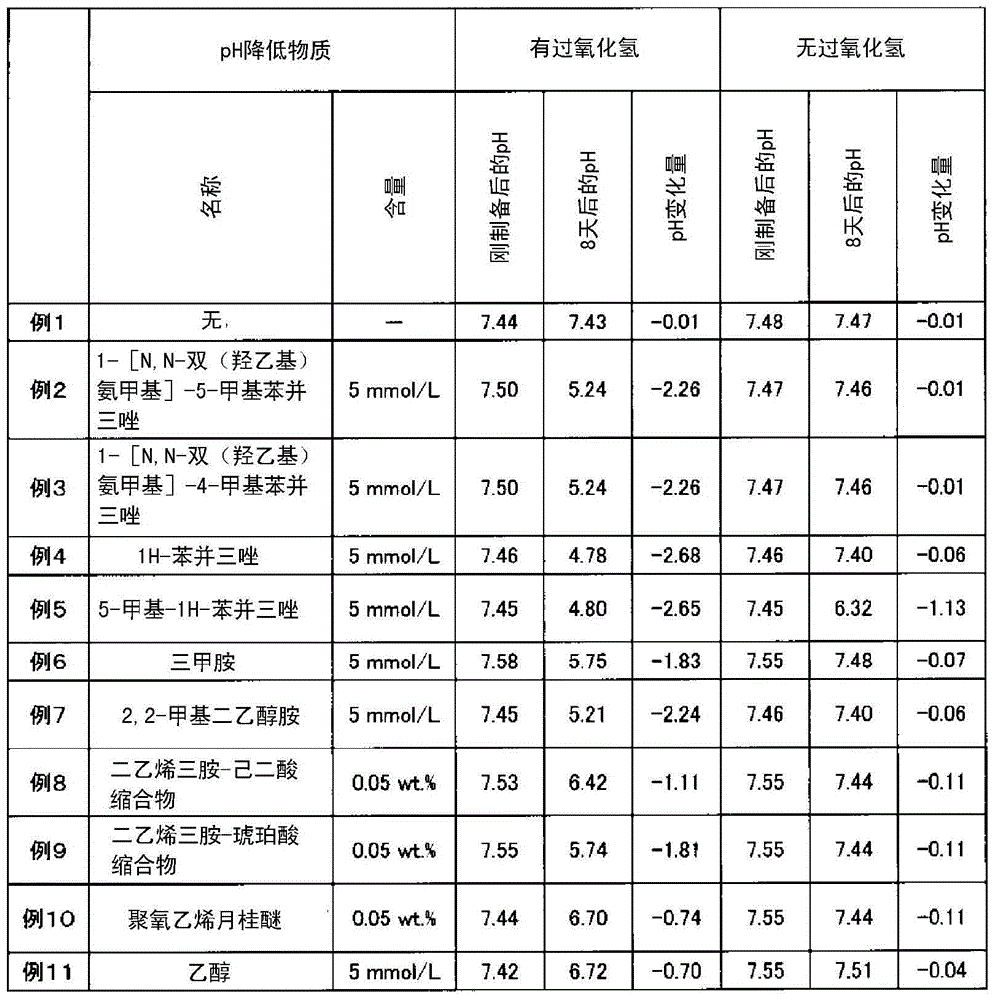

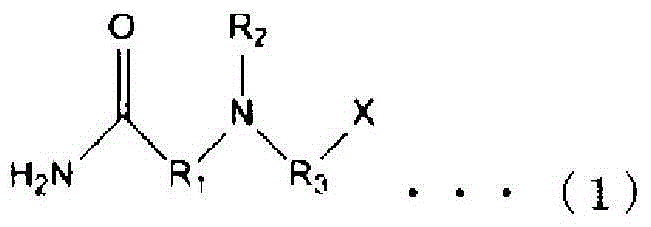

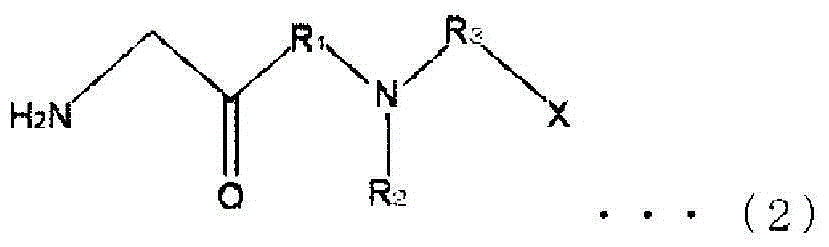

[0115] An oxidizing agent, a pH lowering substance, a pH buffer, a grinding accelerator, a surfactant, and abrasive grains were mixed into water to prepare polishing compositions of Examples 1 to 9. Separately, an oxidizing agent, a pH lowering substance, a compound instead of a pH buffering agent, a polishing accelerator, a surfactant, and abrasive grains were mixed in water to prepare polishing compositions of Comparative Examples 1 to 5. Details of the pH buffering agent or the compound replacing the pH buffering agent in the polishing compositions of Examples 1 to 9 and Comparative Examples 1 to 5 are shown in the "Name" column in the "pH buffering agent or the compound replacing it" column of Table 3. and "Content" column. It should be noted that although not shown in Table 3, the polishing compositions of Examples 1 to 9 and Comparative Examples 1 to 5 all contain 51.6 g / L of 31% by weight hydrogen peroxide aqueous solution (i.e. 16 g / L) as an oxidizing agent. L of hydr...

Embodiment 11~21 and comparative example 11~17)

[0134] An oxidizing agent, a pH lowering substance, a pH control agent, a grinding accelerator, a surfactant, and abrasive grains were mixed into water to prepare polishing compositions of Examples 11 to 21. Separately, an oxidizing agent, a pH lowering substance, a compound instead of a pH controller, a polishing accelerator, a surfactant, and abrasive grains were mixed in water to prepare polishing compositions of Comparative Examples 11 to 17. The details of the pH control agent or the compound that replaces the pH control agent in the polishing compositions of Examples 11 to 21 and Comparative Examples 11 to 17 are as shown in the "pH control agent or the compound that replaces it" column of Table 6 and Table 7. Name" column and "Content" column. It should be noted that, although not shown in Table 6 and Table 7, the polishing compositions of Examples 11 to 21 and Comparative Examples 11 to 17 all contained 51.6 g / L of 31% by weight aqueous hydrogen peroxide solution as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com