Ceramic teapot fettling and shaping machine provided with double wheel heads

A dual-wheel head, shaping machine technology, used in ceramic shaping machines, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

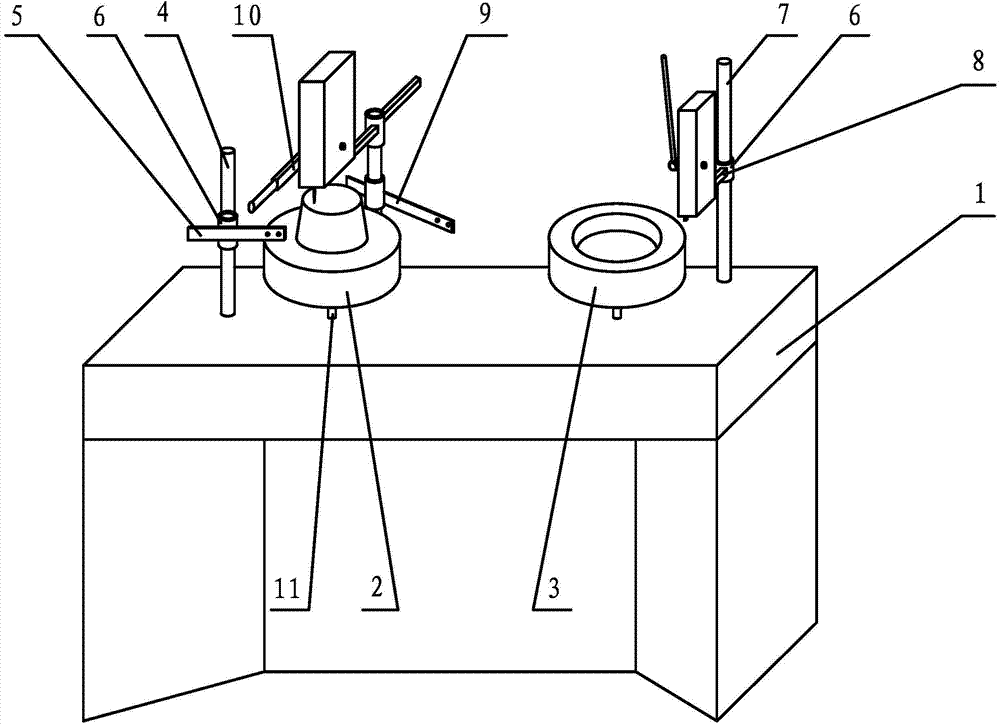

[0016] The technical scheme of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

[0017] The double wheel head ceramic teapot trimming and shaping machine of the present invention comprises a pot lid wheel head 2 and a pot body wheel head 3, and the pot lid wheel head 2 and the pot body wheel head 3 are installed on the frame 1 through respective rotating shafts 11 , the pot lid wheel head 2 and the pot body wheel head 3 are driven by the transmission mechanism connected by the rotating shaft 11 to rotate around their own vertical axis respectively, corresponding to the pot lid wheel head 2, and the lid trimming for trimming the lid is set on the frame 1 Cutter mechanism, the lid trimming cutter mechanism 9 of trimming lid and the lid punching cutter mechanism 10 that offers exhaust hole on the lid, corresponding to the kettle body wheel head 3, the frame 1 is provided with a trimmer for trimming the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com