Fabricated heat storage and release module and intelligent control phase change heat storage and release system

A heat storage and release, assembled technology, applied in the field of phase change energy storage, can solve the problems of heat loss, large fluctuation of heat production, and insufficient effective expansion of the heat storage unit, so as to achieve enhanced regulation and synergy, and speed up the start-up time. , the effect of avoiding waste heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

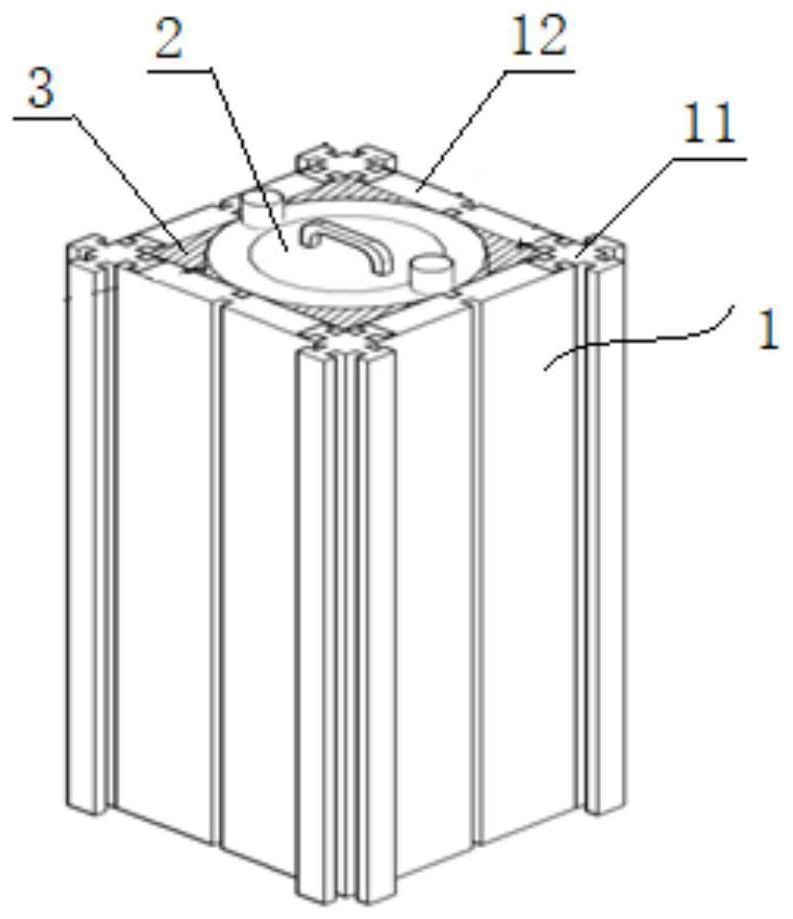

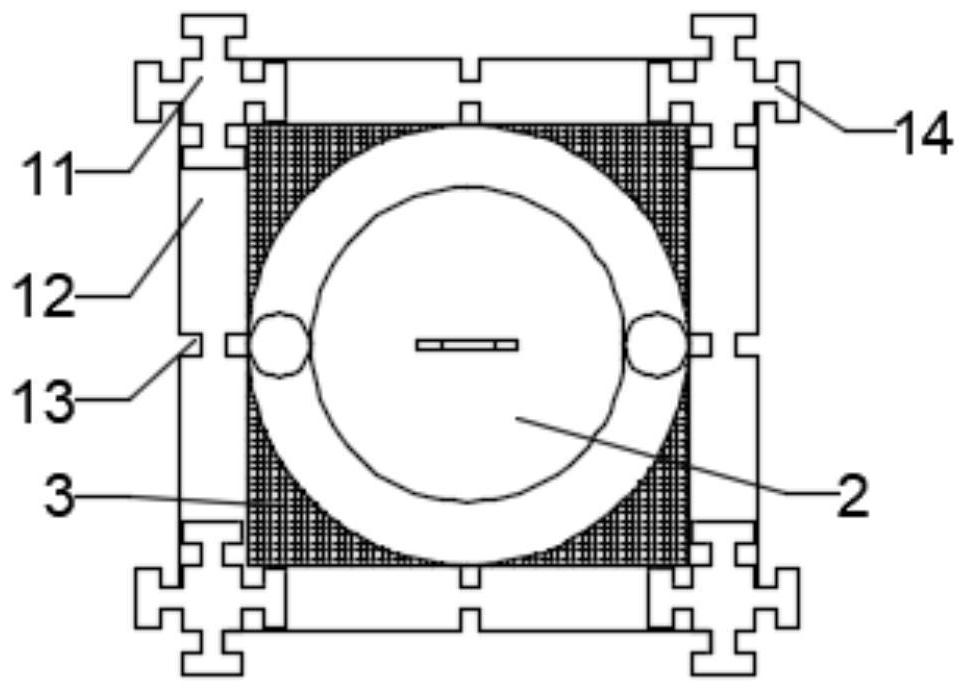

[0037] An assembled heat storage and release module, such as figure 1 As shown, it includes a heat storage and release unit 2 and a fabricated shell 1, such as Figure 4-6As shown, the heat storage and release unit 2 includes a cylindrical inner shell 24 and an outer shell 25, the space between the inner shell 24 and the outer shell 25 serves as a fluid channel 26, and the top of the fluid channel 26 is symmetrically provided with two fluid inlets / inlets 21 , used to connect the supply / return piping. The cavity within the inner shell 24 is filled with a phase change material 29 . A number of inner wall fins 27 are evenly distributed on the inner wall of the inner shell 24 in the longitudinal direction, and a number of outer wall fins 28 are evenly distributed in the longitudinal direction on the outer wall of the inner shell 24 to enhance the heat exchange efficiency between the fluid and the phase change material. The top of the heat storage and release unit 2 is provided w...

Embodiment 2

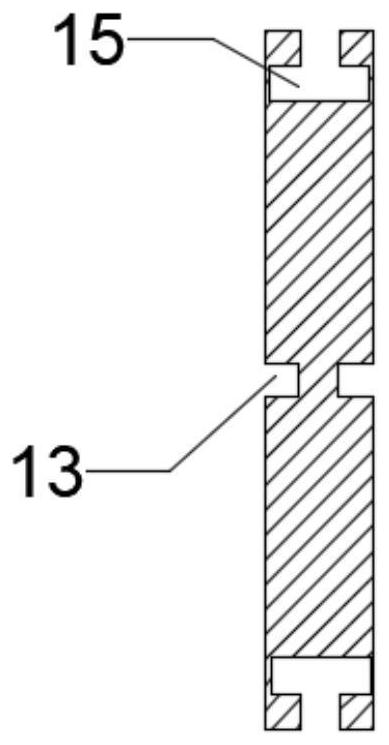

[0041] like Figure 7-8 As shown, the assembled casing 1 in this embodiment includes an assembly plate 12 and a columnar connecting piece 11 , and the assembly plate 12 and the connecting piece 11 have the same height and the same height as the heat storage and release unit housing. The left and right ends of the assembly plate 12 are provided with T-shaped second ridge-shaped guide rails 16, and the two sides of the middle of the assembly plate 12 are provided with rectangular third groove-shaped guide rails 13. The position and size of the third groove-shaped guide rails 13 should be consistent with the heat storage and discharge. The third ridged rail 23 on the unit housing corresponds. The connecting member 11 is provided with four inverted T-shaped second groove-shaped guide rails 17 diagonally, and the shape and size of the second ridge-shaped guide rails 16 and the second groove-shaped guide rails 17 are matched. The structure of the heat storage and release unit and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com