Compound microbial fertilizer and production method thereof

A technology for compound microorganisms and fertilizers, applied in the field of compound microorganism fertilizers and their production, can solve the problems of insufficient or wasteful fertilization amount, moderate difficulty ratio, and high cost, and achieve the effects of reducing planting costs, reducing fertilizer costs, and increasing yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

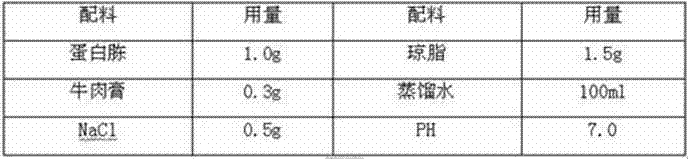

[0023] The preparation method of the cultivation of the nitrogen-fixing bacillus strain and the strain fermentation product: comprise the following steps: 1, a small amount of strain is cultivated in the test tube culture medium, and the batching of the test tube culture medium is as shown in table 1, and the nitrogen-fixing bacillus strain Incubate at 30°C for 24-48 hours. 2. Inoculate the bacterial classification cultivated on the test tube base to the liquid culture medium to cultivate the liquid bacterial classification (first-level bacterial classification), and the liquid culture medium for cultivating the liquid bacterial classification is identical with the batching of the used test tube culture medium of step 1, Just without the agar. 3. Expand the culture of the liquid strains produced by the liquid culture into secondary strains. The culture medium used is the same as the liquid culture medium in step 2, and cultivated in an aerobic fermenter. 4, configuration soli...

Embodiment 1

[0039] Example 1: 35 kg, 30 kg, 20 kg and 15 kg of fermented products of Bacillus nitrogen-fixing, Bacillus subtilis, Bacillus megaterium and Bacillus jelly-like were weighed respectively, and mixed uniformly to obtain a compound microbial fertilizer.

Embodiment 2

[0040] Example 2: 30 kg, 28 kg, 22 kg and 16 kg of fermented products of Bacillus nitrogen-fixing, Bacillus subtilis, Bacillus megaterium and Bacillus jelly-like were respectively weighed and mixed uniformly to obtain a compound microbial fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com