Ultra-thin fiber cleaning rope and manufacturing method thereof

A superfine fiber and rope technology, applied in the field of ropes, can solve the problem of low cleaning performance, and achieve the effects of reasonable processing technology, super cleaning performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

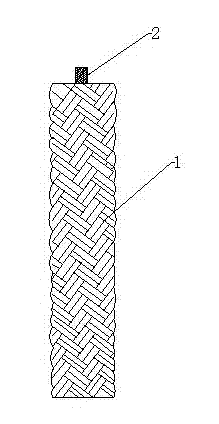

Image

Examples

preparation example Construction

[0017] The preparation method of microfiber cleaning rope comprises the following steps:

[0018] 1. Material selection: use surface-treated polyurethane superfine fiber filaments, and its specification is 630D-1260D; the surface treatment process of polyurethane superfine fiber filaments is: by weight percentage, trihydroxyphenylethane and diazonaphthoquinone The sulfonate is made into a photosensitive mixed solution according to the ratio of 25% to 75%, and the polyurethane superfine fiber filament is put into a photosensitive mixed solution that is not water-soluble but soluble in alkaline aqueous solution and placed in the dark for 1 hour to obtain Polyurethane microfiber filament with better stain removal and water absorption properties.

[0019] 2. Doubling: 2-4 polyurethane superfine fiber filaments are combined into one strand under the same tension condition by the doubling machine.

[0020] 3. Twisting: After paralleling, the polyurethane superfine fiber filaments a...

Embodiment 1

[0025] The preparation method of microfiber cleaning rope comprises the following steps:

[0026] (1) Select surface-treated polyurethane superfine fiber filaments, the specification of which is 630D; the surface treatment process of polyurethane superfine fiber filaments is: by weight percentage, trihydroxyphenylethane and diazonaphthoquinone sulfonic acid According to the ratio of 25% and 75%, the ester is made into a photosensitive mixed solution, and the polyurethane microfiber filaments are put into a photosensitive mixed solution that is not water-soluble but soluble in alkaline aqueous solution and placed in the dark for 1 hour;

[0027] (2) Doubling: Two polyurethane superfine fiber filaments are combined into one strand under the same tension condition by the doubling machine;

[0028] (3) Twisted thread: The polyurethane superfine fiber filaments after paralleling are twisted through the 814 type twisting machine, the twist is 40-65 twists / m, and the transmission bel...

Embodiment 2

[0033] The preparation method of microfiber cleaning rope comprises the following steps:

[0034] (1), select surface-treated polyurethane superfine fiber filaments, and its specification is 1000D; the surface treatment process of polyurethane superfine fiber filaments is the same as in Example 1;

[0035] (2) Doubling: 3 polyurethane superfine fiber filaments are combined into one strand under the same tension condition by the doubling machine;

[0036] (3) Twisted thread: The polyurethane superfine fiber filaments after paralleling are twisted through the 814 type twisting machine, the twist is 40-65 twists / m, and the transmission belt of the twisting machine is tight, and each filament must pass Tension regulator control, regularly measure its speed and twist;

[0037] (4) Heat setting: Put the twisted strands in a completely relaxed state, put them into the yarn steaming machine for steam heat and humidity setting, the heat setting conditions are: 100°C, 0.12Mpa, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com