Pile head joint waterproof processing device and construction method thereof

A node waterproofing and processing device technology, which is applied in protection devices, infrastructure engineering, construction, etc., can solve problems such as difficult construction, large amount of labor, and failure of waterproofing effect, so as to reduce the amount of earth excavation and reduce construction waste , The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

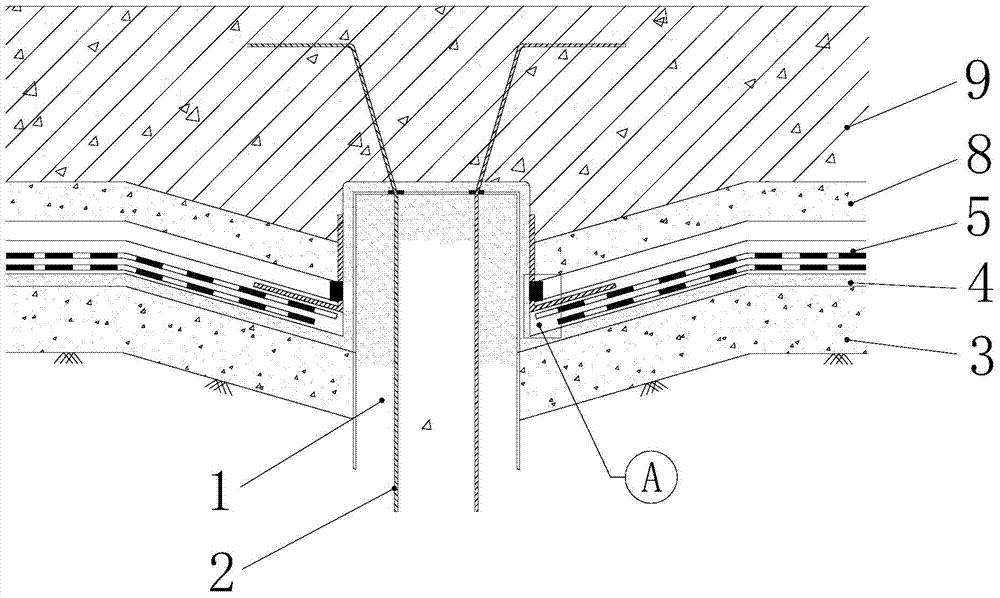

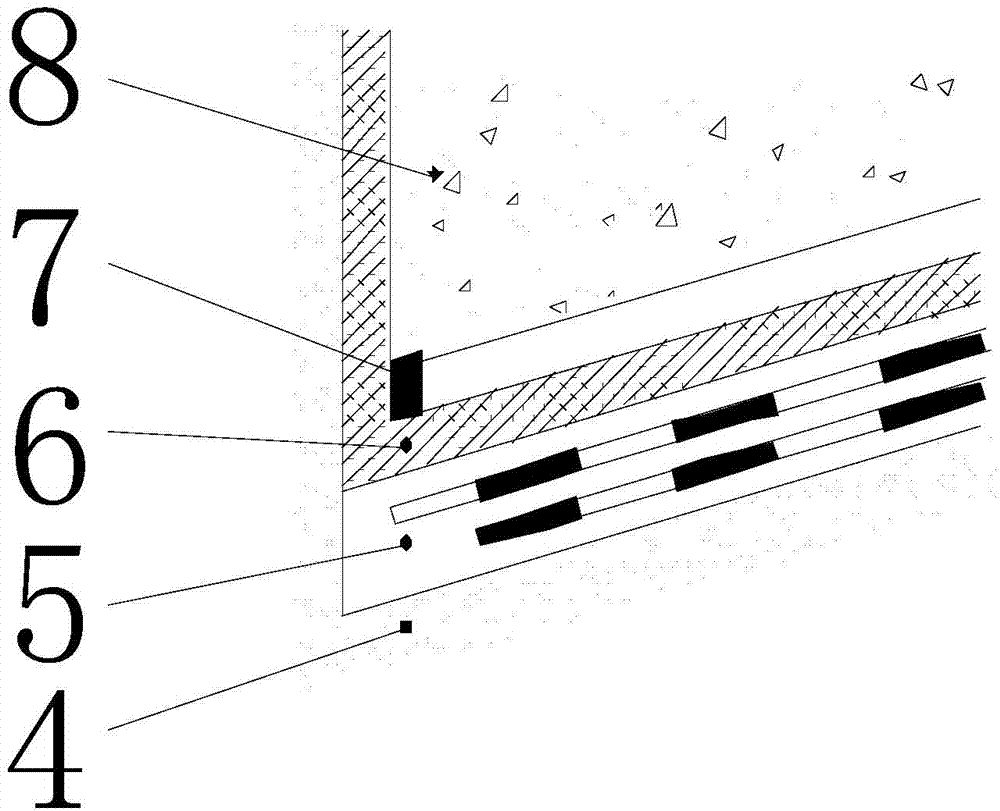

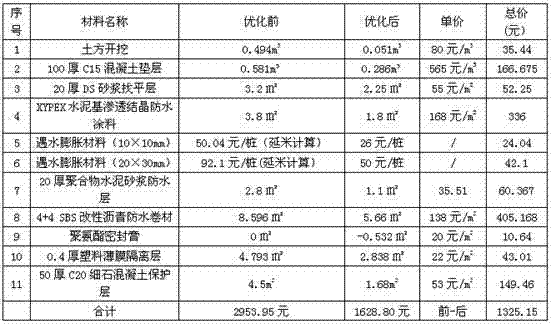

[0035] like Figure 1-2 As shown, a pile head node waterproof treatment device described in the embodiment of the present invention includes a pile head 1, and steel bars 2 are provided on the top and inside of the pile head 1, and the steel bars 2 on the top of the pile head 1 are all inclined upward And the top is horizontally outward, the bottom of the pile head 1 is buried in the base soil layer, the base soil layer around the pile head 1 is provided with a trumpet-shaped opening centered on the pile head 1, and the base soil layer around the opening is Horizontal distribution; the slope of the trumpet-shaped opening and the horizontal base soil layer around the opening are provided with a concrete pouring layer 3, and the thickness of the concrete pouring layer 3 on the slope of the trumpet-shaped opening is the same; the top of the pile head 1, The side and the upper surface of the concrete pouring layer 3 are continuously provided with a cement mortar layer 4, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com