Controllable drop point safety impact grab

A safe impact and controllable technology, applied in the direction of mechanically driven excavators/dredgers, etc., to ensure the reliability of clamping and overcome the effects of using defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

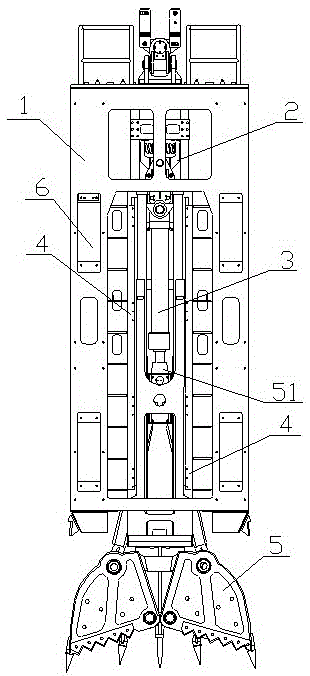

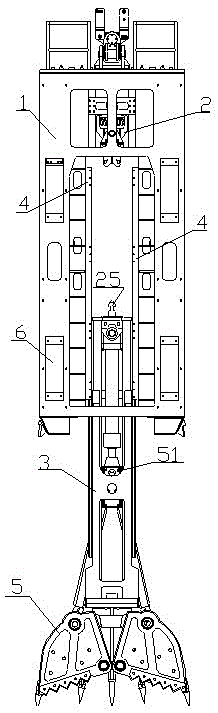

[0018] Such as figure 1 As shown, a safety impact grab with controllable landing point includes a hydraulically controlled opening and closing grab bucket 5, which is characterized in that it also includes a clamping mechanism 2, a frame 1 and a guide column 3,

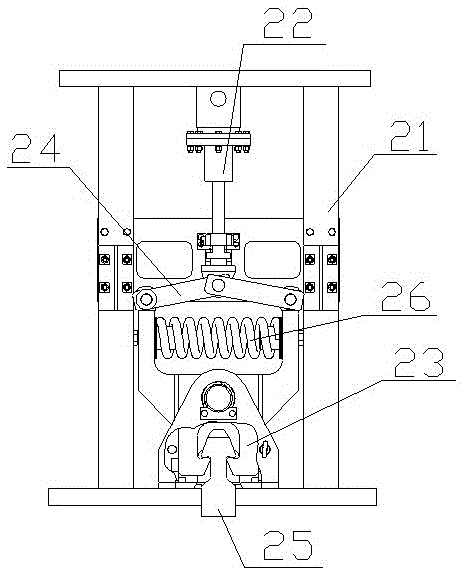

[0019] The clamping mechanism 2 includes an oil cylinder 22, a support 21, a collet 25, two connecting rods 24, two clamp arms 23 and a spring 26; the support 21 includes two side plates and positioning plates symmetrically arranged on the sides of the two side plates, The locating plate is provided with chute symmetrically; two connecting rods 24 have one end connected with the telescopic end pin of the oil cylinder 22, the telescopic end of the oil cylinder 22 is located in the chute of the bracket 21, the other end of the two connecting rods 24 They are respectively connected with the pin shafts at the top of the two clamp arms 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com