Hydraulic bearing-type riser universal joint device

A universal joint and riser technology, which is applied in the direction of drill pipe, casing, underwater drilling, etc., can solve the problems of high performance requirements such as high performance requirements for hydraulic cylinder piston materials and service life, high cost, and many difficulties in production and processing. Achieve the effects of easy processing and transportation, simple production and good replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

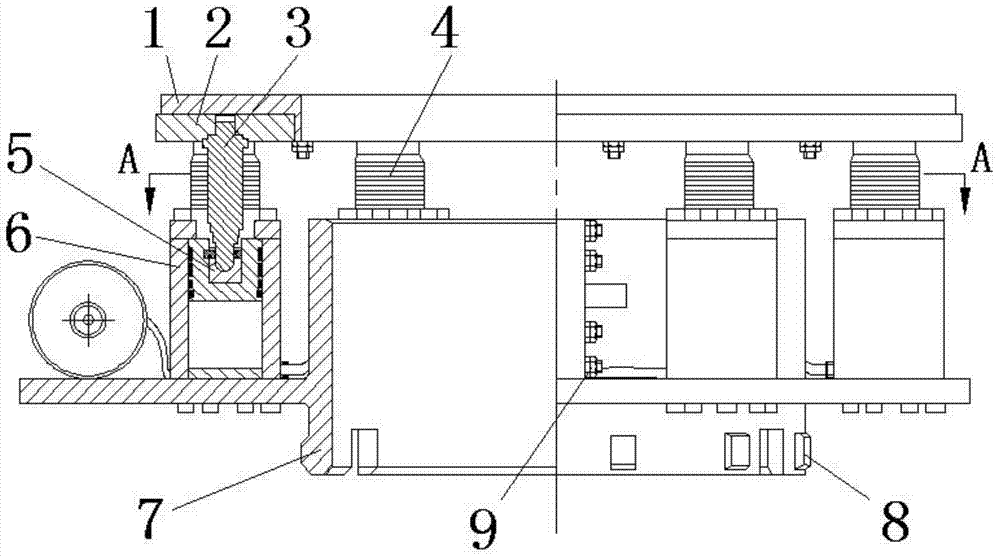

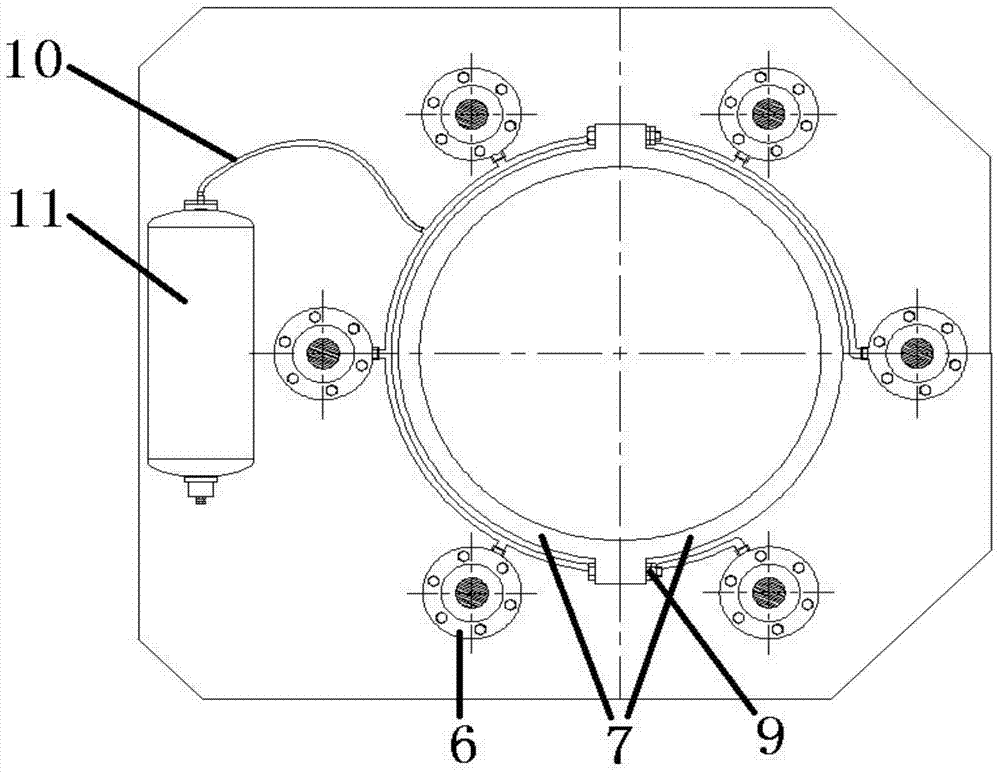

[0016] refer to figure 1 , the hydraulic load-bearing type riser universal joint device of the present invention is installed between the riser chuck and the turntable, and includes three parts: the main structure, the pressure-bearing element and the hydraulic power system, wherein the main structure consists of the body 7 and its connecting bolts 9 , a positioning block 8, a chuck connecting plate 1, and a hydraulic cylinder connecting plate 2, the body 7, a positioning block 8, and connecting fasteners 9 form a support base; the pressure-bearing element consists of a guide shaft 3, a sheath 4, a guide seat 5, The hydraulic cylinder 6 is composed; the hydraulic power system is composed of a hydraulic pipeline 10 and an accumulator 11. The pressure-bearing components are evenly distributed along the circumferential direction, and the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com