Cylinder cover of natural gas engine

A technology for engine cylinders and natural gas, which is applied to engine components, combustion engines, machines/engines, etc., can solve problems such as lowering the compression ratio, thickness of the cylinder head bottom plate, complex structure of the cylinder head, and the valve chain, so as to improve reliability and reduce Less wear, improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

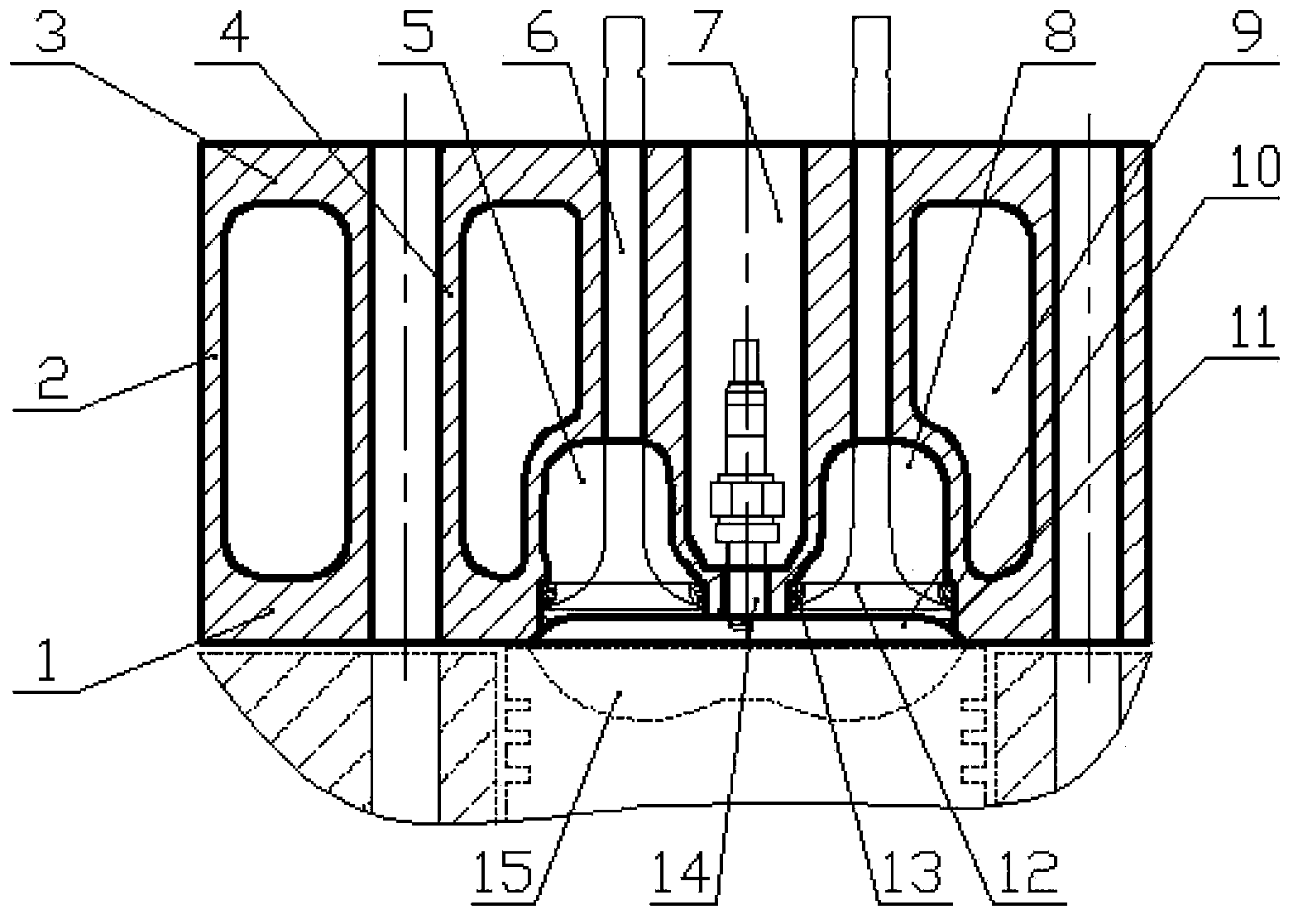

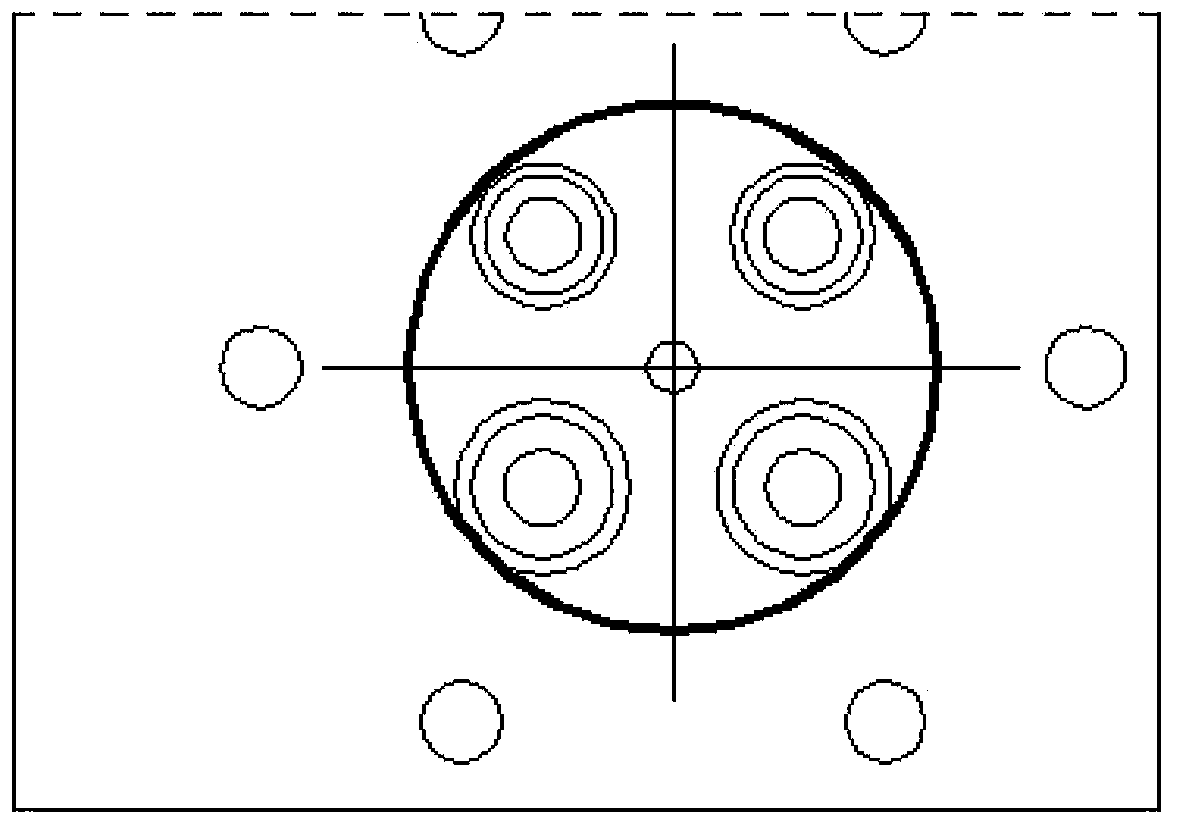

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0017] The cylinder head of the engine is used to close the cylinders and form the combustion chamber. The overhead valve engine cylinder head, in addition to the cooling water jacket, also has valve devices, intake and exhaust passages, etc. The cylinder head belongs to the gas distribution mechanism in the field of internal combustion engines, and is mainly used to close the upper part of the cylinder to form the combustion chamber. And as the support of camshaft and rocker shaft as well as intake and exhaust pipes. The function of the cylinder head is mainly to draw air into the cylinder, and then the spark plug ignites the combustible mixture to drive the piston to do work, and the exhaust gas is discharged from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com