D-shaped latent heat storage component

A latent heat storage and component technology, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of low thermal conductivity and low heat exchange performance of heat storage devices, and achieve uniform temperature distribution and storage The effect of increased heat and increased melting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

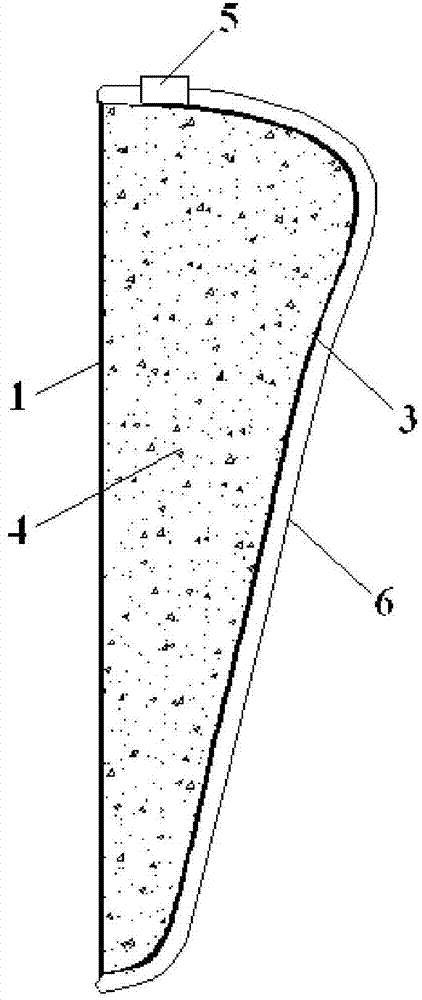

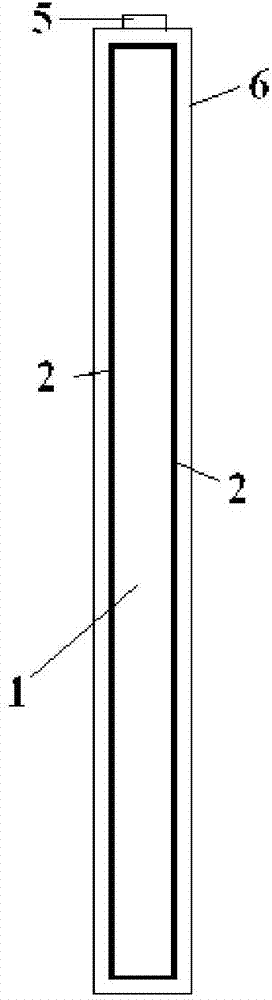

[0040] In this embodiment, the "D-shaped" latent heat storage member has a height of 30 cm and a thickness of 10 cm. The phase change material used in this embodiment is paraffin (n-octadecane). The curve obtained by rotating the profile curve of the curved outer wall of the component by 90 degrees in the counterclockwise direction satisfies the distribution pattern of the Asym2Sig curve in the Peak Functions function, and its function expression is:

[0041] y=y 0 +A(1 / (1+exp(-(x-x c +w 1 / 2) / w 2 )))(1-1 / (1+exp(-(x-x c +w 1 / 2) / w 3 )))

[0042] Where: y 0 =-23.2,x c =8.3, A=34.8, w 1 = 46,w 2 =18.6,w 3 = 0.5.

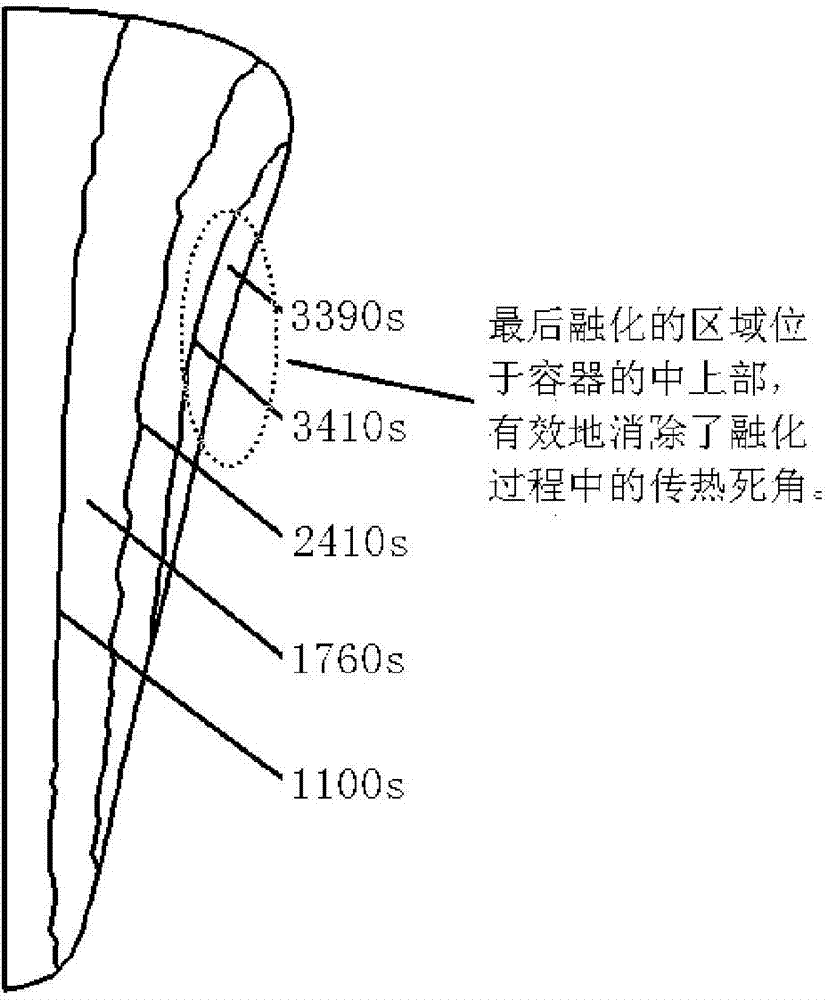

[0043] The phase interface views of the components of this embodiment at different moments during the melting process image 3 ,From image 3 It can be seen that the phase interface at the initial moment is parallel to the heating wall, and then as the melting process proceeds, natural convection begins to take effect, and the phase interface gradually ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com