Common optical path multiple inclined wave surface compensation non-zero position interferometry device

A technology of interferometry and oblique waves, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high-quality and large-diameter beam-splitting prisms, the difficulty of processing and manufacturing, increasing the cost of processing and installation, and the inability to achieve measurement, etc., to achieve a huge industry Potential for optimization, expansion of dynamic measurement range, and ease of engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

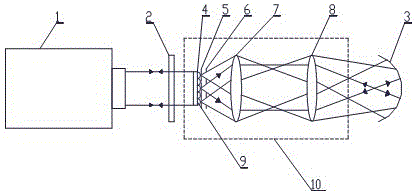

[0013] combine figure 1 , the common optical path multiple inclined wave surface compensation non-zero position interferometry device is composed of a Fizeau interferometer 1, a standard flat crystal 2, a free-form surface gradient compensation module 10 and a free-form surface to be measured 3, the main optical axis of the free-form surface gradient compensation module 10 It coincides with the main optical axis formed by the Fizeau interferometer 1, the standard flat crystal 2 and the free-form surface 3 to be measured. The main optical axis of the device constitutes the main optical axis of the interferometry device, wherein the free-form surface gradient compensation module 10 includes a microlens array 4, a pinhole array 5, a dynamic mask 6, a collimating objective lens 7 and a standard lens 8, and the microlens array 4 is located in the parallel optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com