Multi-dimensional and multidirectional stress-strain monitoring system

A stress-strain and monitoring system technology, applied in measurement devices, instruments, etc., can solve the problems of spatial multi-dimensional and multi-directional stress-strain distributed optical fiber monitoring without public research results, and achieve a complete and novel design concept, high precision, and low monitoring costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: In this embodiment, the spatial two-dimensional three-way stress strain gauge is used as one of the preferred examples of the optical fiber monitoring device, so as to emphasize the authenticity, feasibility and inventive concept of the present invention. The following takes the SMF-28e ordinary single-mode fiber as an example to illustrate the specific use scheme of the monitoring system, but the use of the system is not limited to this.

[0030] (1) Building the system of the present invention

[0031] (1) Construction of the system device of the present invention

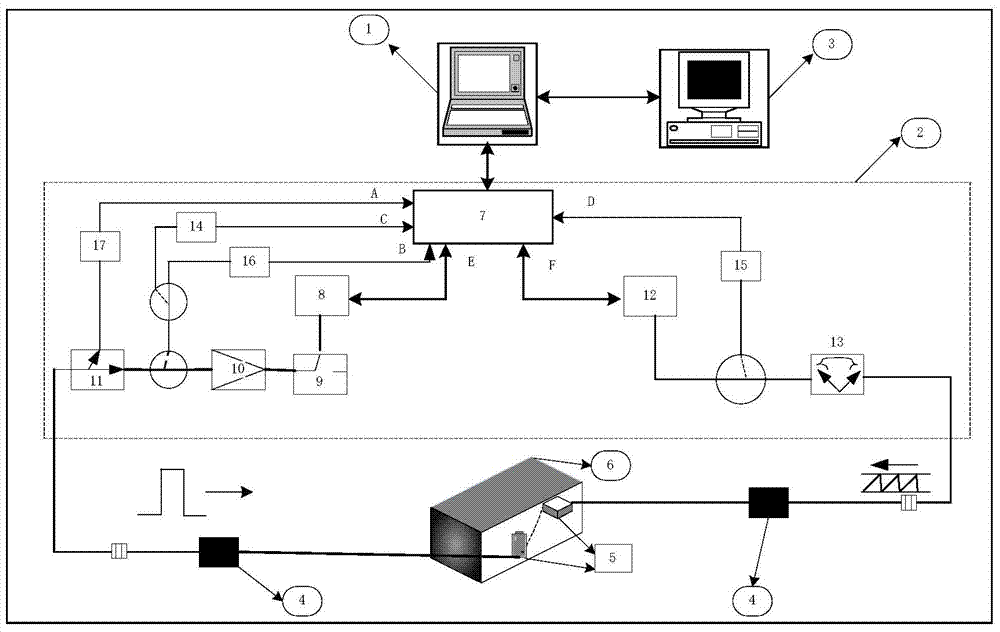

[0032] Multi-dimensional and multi-directional stress-strain monitoring systems, such as figure 1 As shown, it includes an information acquisition device 1, an optical fiber monitoring device 2, a data analysis platform 3, a junction box 4, and an optical fiber sensing device 5 arranged in the structure to be measured 6; the optical fiber sensing device 5 is used to sense the stress and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com