Piezoelectric ceramic sensitive module and hydraulic concrete structure health monitoring test platform

A technology of hydraulic concrete and piezoelectric ceramics, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve the lack of monitoring of large-volume concrete and plain concrete, the large size of hydraulic concrete structures, and the lack of improvement in structural health monitoring. and other problems, to achieve the effect of complete and novel design concept, complete and rigorous design thinking, and simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

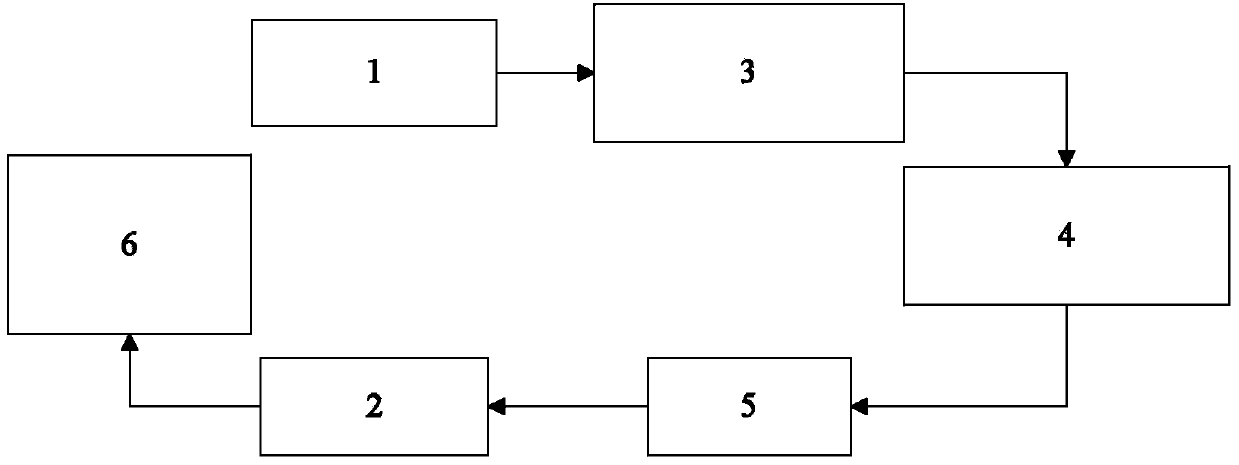

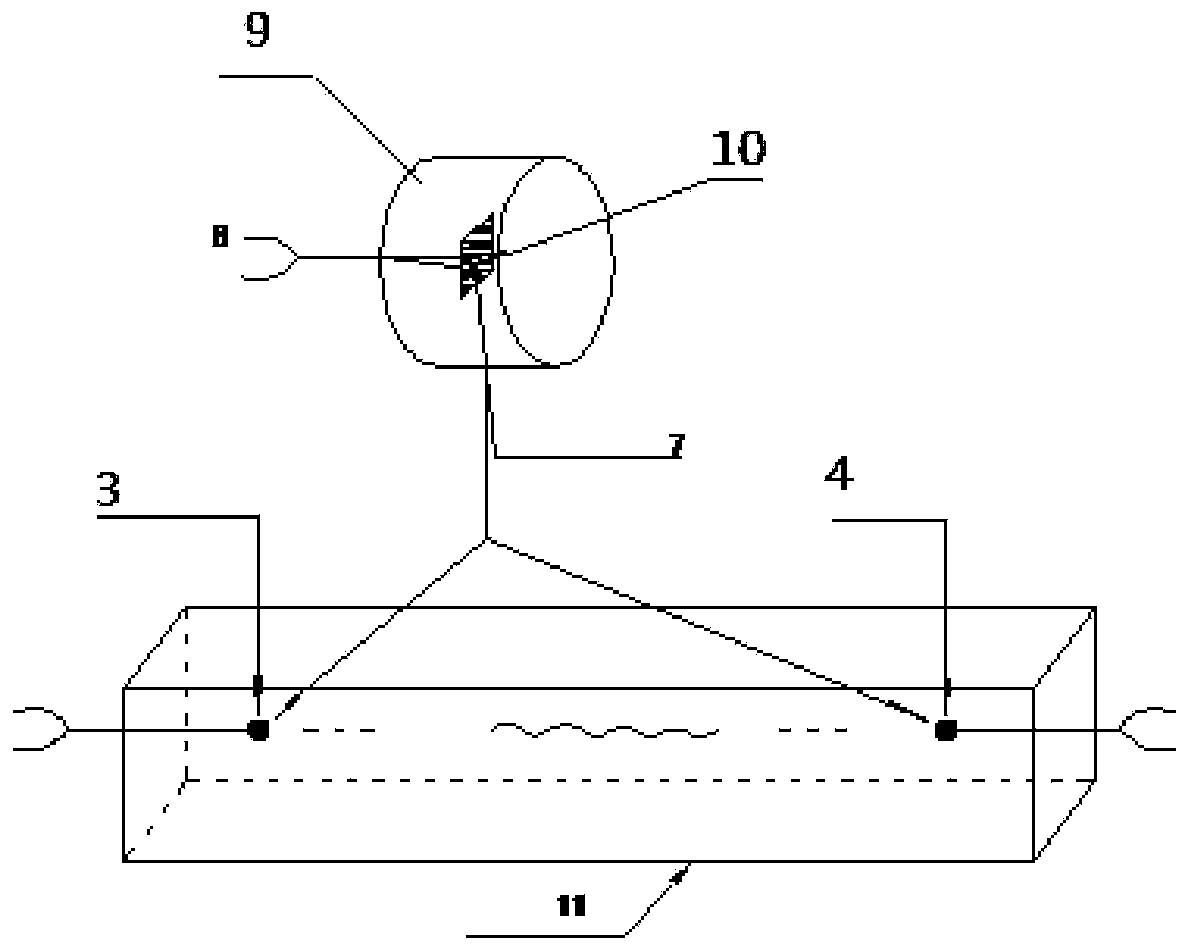

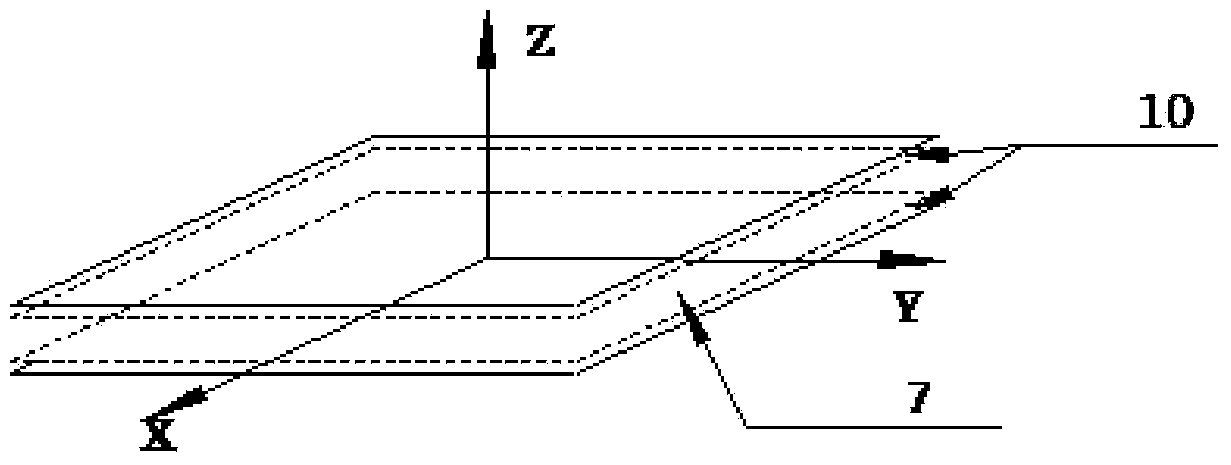

[0024] Embodiment 1: The test platform of the present invention is mainly made up of six independent systems, and the core component is a concrete piezoelectric ceramic smart module, and the following uses dSPACE (digital Signal Processing And Control Engineering) system, Agilent arbitrary waveform generator, MATLAB / Simulink The control system development and structure test platform, and the concrete piezoelectric ceramic smart module of Φ25mm×(25~30)mm cylinder are taken as examples to illustrate the specific use plan of this test platform, but the use of this platform is not limited to this.

[0025] (1) Design and preparation of piezoelectric ceramic smart modules:

[0026]Piezoelectric ceramics belong to ferroelectric materials, and are a kind of artificial piezoelectric materials. The materials produce piezoelectric effect of electrical signals under pressure. This test uses PIC151 piezoelectric ceramic chips from PCB Company. Cut the piezoelectric ceramic sheet with a gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com