Method for testing local mode of automotive sheet part

A technology of modal testing and testing methods, applied in the testing of machine/structural components, vibration testing, measuring devices, etc., can solve problems such as the increase of testing accuracy errors, suppress local vibration, improve testing efficiency, and save testing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

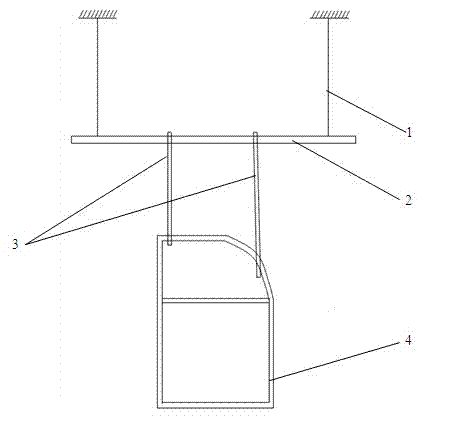

[0022] Taking the outer panel of the car door as an example below, the present invention will be further described in conjunction with the accompanying drawings.

[0023] Step 1: The hanger 2 is suspended on the vehicle through the wire rope 1. Simulate the "free-free" boundary condition, hang the door outer panel 4 (excluding door interior parts, glass regulators, glass, rearview mirror, etc.) on the hanger 2 with a soft rubber rope 3, and suspend the door outer panel The connection point should be selected on the window frame of the car door, so that the car door is in a horizontal and free state, see figure 1 .

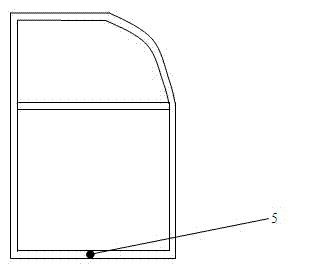

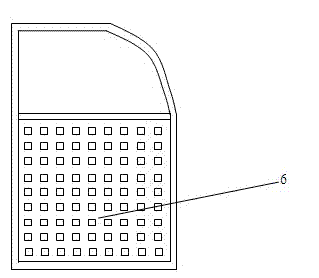

[0024] Step 2: Select several excitation points for pre-test, repeated debugging, and select the point that can best stimulate the frequency response function of the door as the pre-selected best excitation point (that is, the best excitation position), which usually has a higher local stiffness. In this example, when the door is in a horizontal free state, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com