Light-curing thermal-curing resin composition

A thermal curing resin, light curing technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

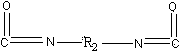

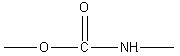

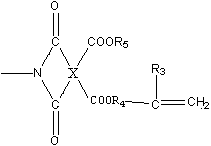

[0066] In a four-neck flask equipped with a stirrer, a reflux condenser, and a nitrogen tube, feed nitrogen, add 25.00 grams (0.1 moles) of xylylmethane 4,4-diisocyanate, and 15 grams of γ-butyrolactone, and stir After homogenizing, heat to 90 degrees, and then add 11.34 grams (0.035 mole ), polycarbonate diol (product of Asahi Kasei Co., Ltd., PCDL T5651) 25 g (0.025 mol), dimethylolpropionic acid 1.34 g (0.01 mol) and γ-butyrolactone 35 g, this solution was heated , stirred, and after 10 hours, a uniform transparent viscous polymer liquid was obtained. Then add 26.18 grams of pyromellitic dianhydride (0.12 moles) and 25 grams of gamma-butyrolactone in the solution, adjust the reaction temperature to 180 degrees, after becoming a uniform orange-red solution, heat for 2 hours, and then Start to lower the temperature. After the temperature in the reactor drops to 70 degrees, add 20.92 grams (0.18 moles) of hydroxyethyl acrylate and 12 grams of γ-butyrolactone to the reaction s...

Synthetic example 2

[0068] In a four-neck flask equipped with a stirrer, a reflux condenser, and a nitrogen tube, feed nitrogen, add 25.00 grams (0.1 moles) of xylylmethane 4,4-diisocyanate, and 15 grams of γ-butyrolactone, and stir After homogenizing, heat to 90 degrees, and then add 11.34 grams (0.035 mole ), polycarbonate diol (product of Asahi Kasei Co., Ltd., PCDL T5651) 25 g (0.025 mol), dimethylolpropionic acid 1.34 g (0.01 mol) and γ-butyrolactone 35 g, this solution was heated , stirred, and after 10 hours, a uniform transparent viscous polymer liquid was obtained. Then add 26.18 grams of pyromellitic dianhydride (0.12 moles) and 25 grams of gamma-butyrolactone in the solution, adjust the reaction temperature to 180 degrees, after becoming a uniform orange-red solution, heat for 2 hours, and then Start to cool down, after the temperature in the reactor drops to 70 degrees, add 23.40 grams (0.18 moles) of hydroxyethyl methacrylate and 14 grams of γ-butyrolactone to the reaction system, a...

experiment example 1

[0077] Experimental Example 1, Appearance Inspection

[0078] Observe the surface of the developed sample with the naked eye. Compared with before development, it is necessary that the surface gloss does not change. If the surface gloss becomes lighter or the surface is discolored, it is considered that it cannot meet the product requirements in actual production.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap