A polyurethane profile

A polyurethane profile and polyurethane technology, applied in the field of profiles, can solve problems such as poor bending and torsion resistance, corrosion resistance, poor insulation, and low torsional coefficient, and achieve light weight, high torsional strength, and strong economy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

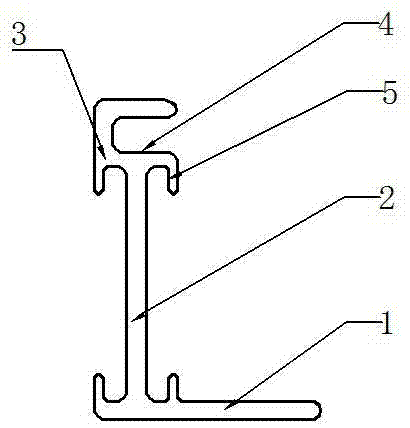

[0024] like figure 1 As shown, the cross-section of the profile is approximately L-shaped or inverted T-shaped. The profile is composed of a bottom plate 1, a top groove 3 and a support plate 2. The top groove 3 is provided with a groove 4 along the axis, and the groove 4 The opening is located on the side of the top groove 3. The bottom plate 1 extends horizontally toward the opening side of the groove 4 . The lower plane of the top groove 3 and the upper plane of the bottom plate are respectively provided with two raised ribs 5 .

Embodiment 2

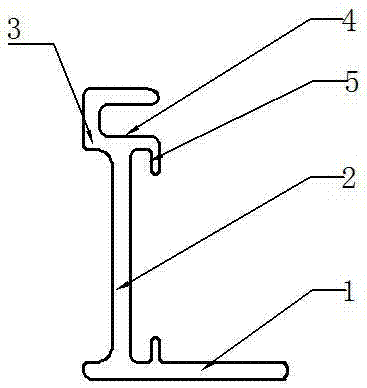

[0026] All the other are identical with embodiment 1, and difference is, as figure 2 As shown, the lower plane of the top groove 3 and the upper plane of the bottom plate 1 are respectively provided with a raised rib 5, and the rib 5 is located on the extended side of the bottom plate.

Embodiment 3

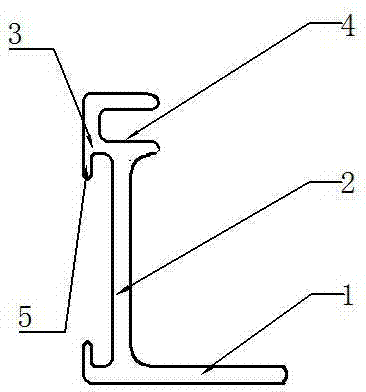

[0028] All the other are identical with embodiment 1, and difference is, as image 3 As shown, the lower plane of the top groove 3 and the upper plane of the bottom plate 1 are respectively provided with a protruding rib 5, and the rib 5 is located on the other side of the extension of the bottom plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com