Method and device for manufacturing double axle tube blanks at one time in a local electric upsetting mode

A half-shaft sleeve and preparation device technology, applied in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to form forgings, high production costs, long procedures, etc., and achieve short production process cycle , high production efficiency and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

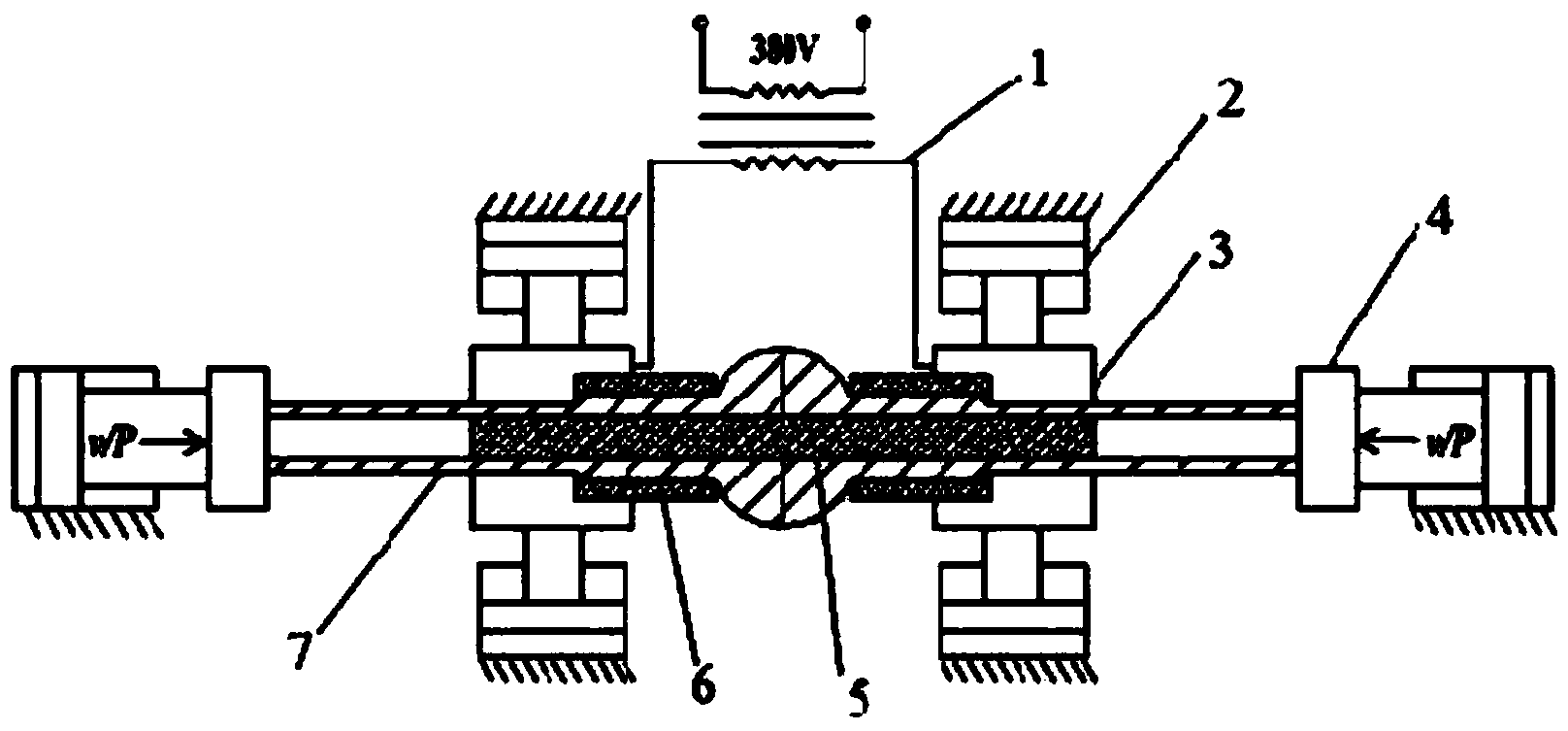

[0023] In specific implementation, such as figure 1 As shown, a half-shaft casing blank one-time two-piece partial electric upsetting preparation device includes

[0024] Two pairs of clamping cylinders 2, the telescopic arms of the two pairs of clamping cylinders 2 are arranged opposite to each other and a pair of clamping parts 3 (ie, electrode materials) are arranged at the front end of the telescopic arms. The holding part 3 is used to realize the clamping of the processed steel pipe 7, and the two pairs of holding parts 3 are made of conductive materials and are respectively connected to the output end of a heating transformer 1 by wires;

[0025] A heating transformer 1, the input end of the heating transformer 1 is used to connect to the power supply, and the output end is connected to the clamping part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com