Single-head press-fitting machine for rear axle hub bearing inner ring

A technology of rear axle hub bearing and pressing machine, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of large space occupation, unstable pressure, difficult processing, etc., so as to achieve a small footprint and reduce processing costs. , The effect of improving the efficiency of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

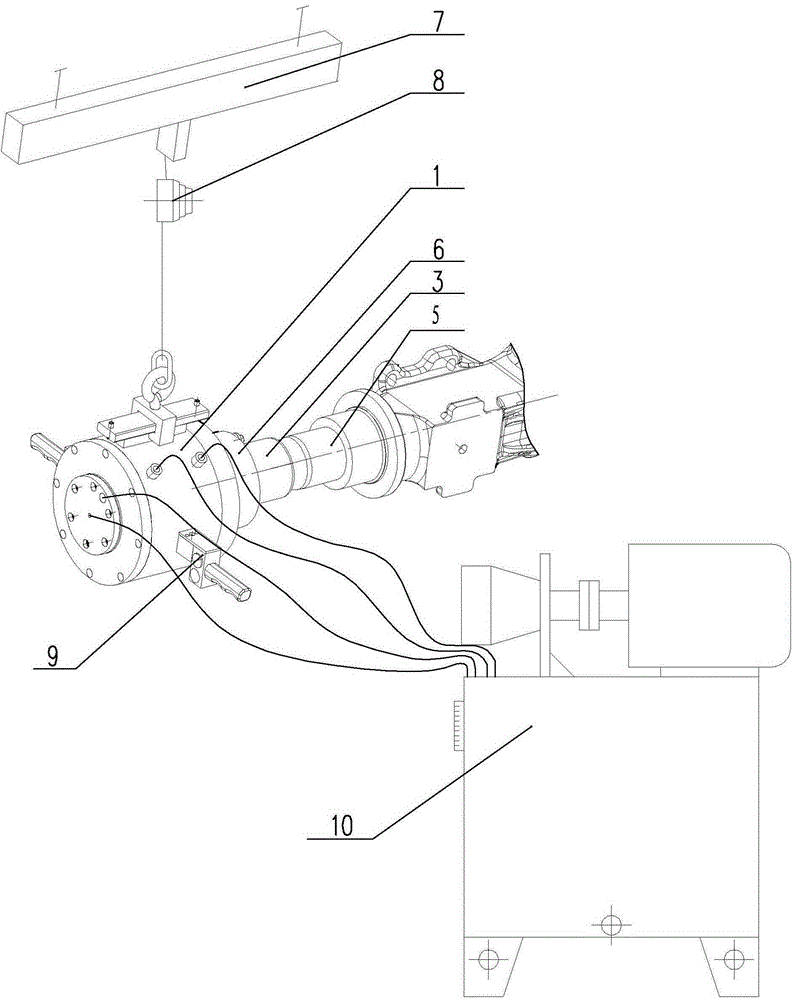

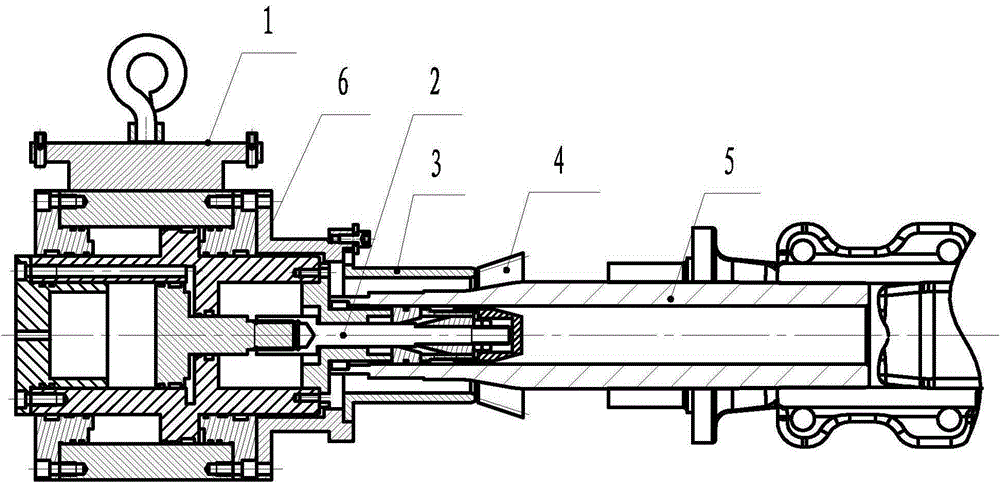

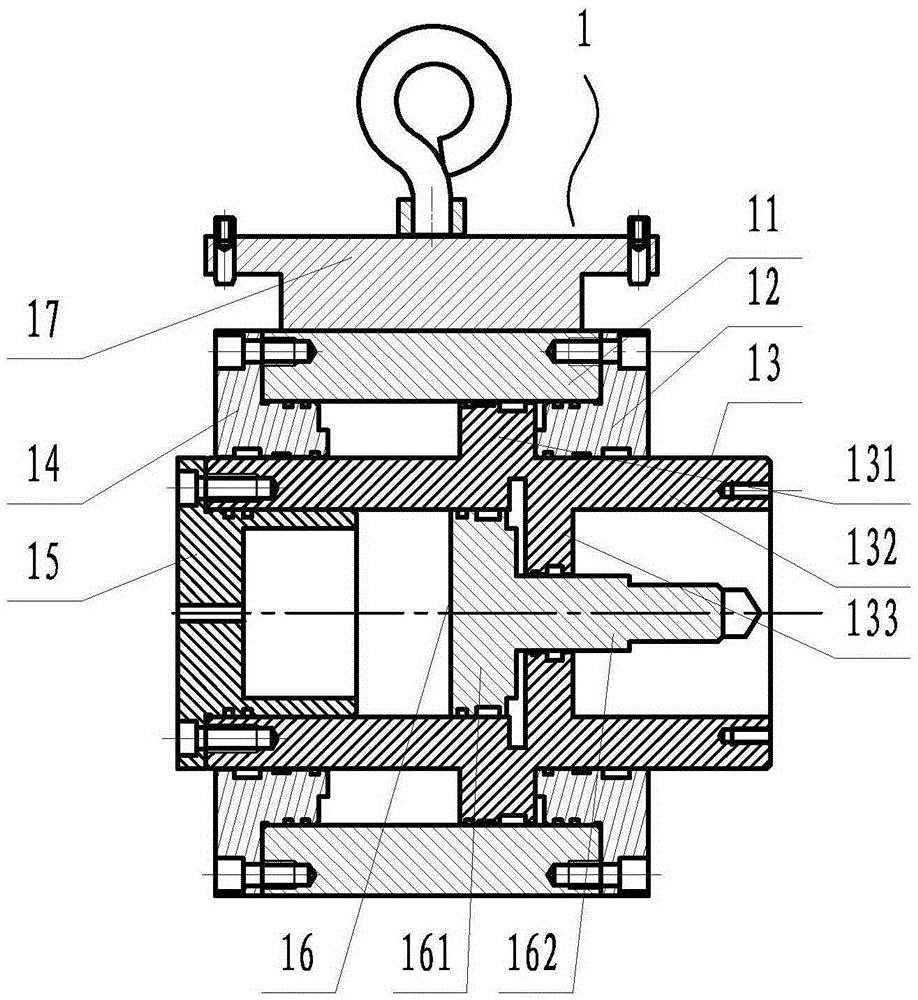

[0040] A single-head press-fitting machine for the inner ring of a rear axle hub bearing, comprising a compound oil cylinder 1, an expanding center mechanism 2, a transition connection plate 6, a bearing pressure head 3 for pressing the inner ring of a wheel hub bearing, and a bearing pressure head 3 for providing the compound oil cylinder 1 with powered hydraulic station 10 (see figure 2 ), the hydraulic station 10 is connected to the compound oil cylinder 1 through the oil pipe, and the compound oil cylinder 1 is flexibly connected to the guide rail 7 through the balance crane 8 (see figure 1), the expanding core mechanism 2 is located in the shaft tube 5 of the rear axle assembly, and the bearing pressure head 3 is located outside the shaft tube 5 of the rear axle assembly. The compound oil cylinder 1 is equipped with a control button 9 for controlling the hydraulic station 10; by pressing the control button 9 of the hydraulic station 10, the hydraulic station 10 can be st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com