A device for printing number marks on hard metal surfaces and its application method

A hard metal and marking technology, applied in the field of machinery, can solve the problems of unseen public reports of use, unseen patented technologies and public reports of literature materials, etc., and achieves reduced fatigue impact, low cost and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

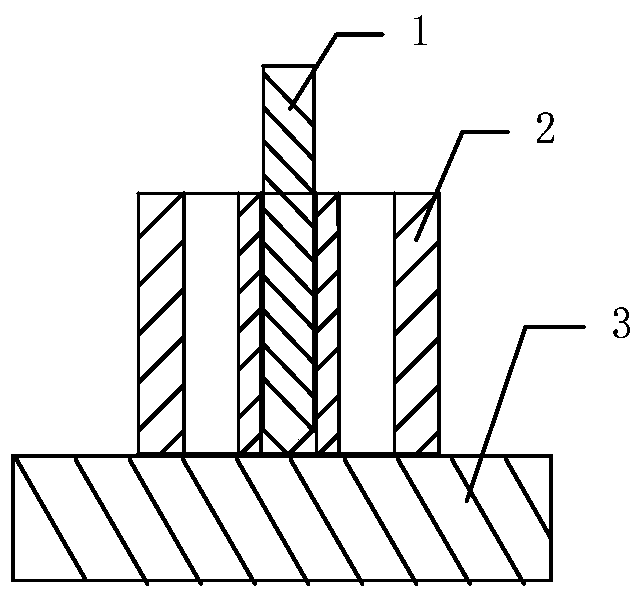

[0028] Print number 7 on the surface of hard metal 3:

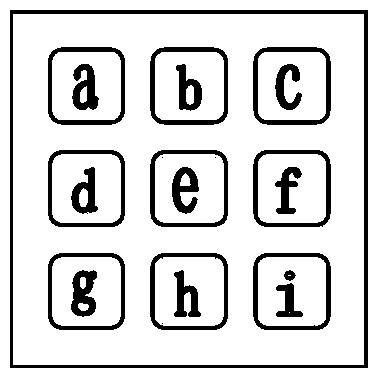

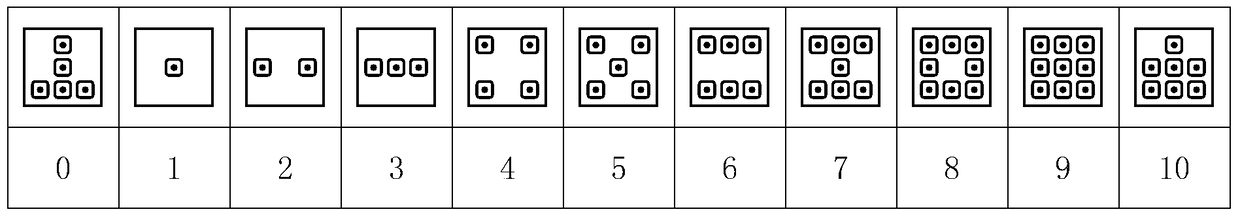

[0029] According to the number 7 to be printed is the number of digits, one digit does not need to be split, refer to the dot type header 1 printing orientation code and number comparison chart, the figure of the dot type header 1 printing orientation mark code corresponding to the number 7 is Choose seven positions a, b, c, e, g, h, and i of the metal fixing bracket 2 to make dots, then place the metal fixing bracket 2 stably on the surface of the hard metal 3, and place the dotted metal prefix 1 Insert the head downwards into the above-mentioned seven corresponding positions of the metal fixing bracket 2 in turn, so that the head of the dot type prefix 1 is in contact with the surface of the metal 3, and then tap the tail of the dot type metal prefix 1 sequentially with a hand hammer, until the task is successfully completed. On the surface of the hard metal 3, a set of clearly printed orientation mark codes correspon...

Embodiment 2

[0031] Print the number 10 on the hard metal 3 surface:

[0032] According to the number 10 to be printed, although the number 10 is a 2-digit position, because it has uniqueness, the dot type header 1 of the present invention prints the orientation mark code and compares the figure to give it a specific code, so it is not necessary to split it. Figure 1 prints the azimuth mark code and the number comparison chart, and the dot type head 1 prints the azimuth mark code corresponding to the number 10. Select seven through-hole positions b, d, e, f, g, h, and i of the metal fixing bracket 2 to make dots, then place the metal fixing bracket 2 on the surface of the hard metal 3 stably, and place the dotted metal characters The head 1 is inserted into the through holes of the above-mentioned seven corresponding positions selected on the metal fixing bracket 2 in sequence, and the tail of the metal word head 1 is hit with a hand hammer until the task is successfully completed, and th...

Embodiment 3

[0034] Print number 205 on the surface of hard metal 3:

[0035] According to the number 205 to be printed, the number 205 can be divided into numbers 2, 0, and 5. Refer to the dotted header 1 to print the orientation mark code and the number comparison chart, and the dotted header 1 corresponding to the number 2 prints the graph of the orientation mark code. for Select the two through-hole positions d and f of the metal fixing bracket 2 to prepare for dotting, and the dot type prefix 1 corresponding to the number 0 prints the pattern of the orientation mark code as Select five through-hole positions b, e, g, h, and i on the metal fixing bracket 2 to prepare for dotting, and the dot type prefix 1 corresponding to the number 5 prints the pattern of the orientation mark code as Select five through-hole positions a, c, e, g, and i on the metal fixing bracket 2 to prepare for dotting, then place the metal fixing bracket 2 on the surface of the hard metal 3 stably, and place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com