Multi-station automatic conveying mechanism for work-pieces

A transmission mechanism and multi-station technology, applied in conveyors, transportation and packaging, etc., can solve the problems of low market competitiveness, high manufacturing costs, and high labor costs, and achieve high work efficiency, fast response, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

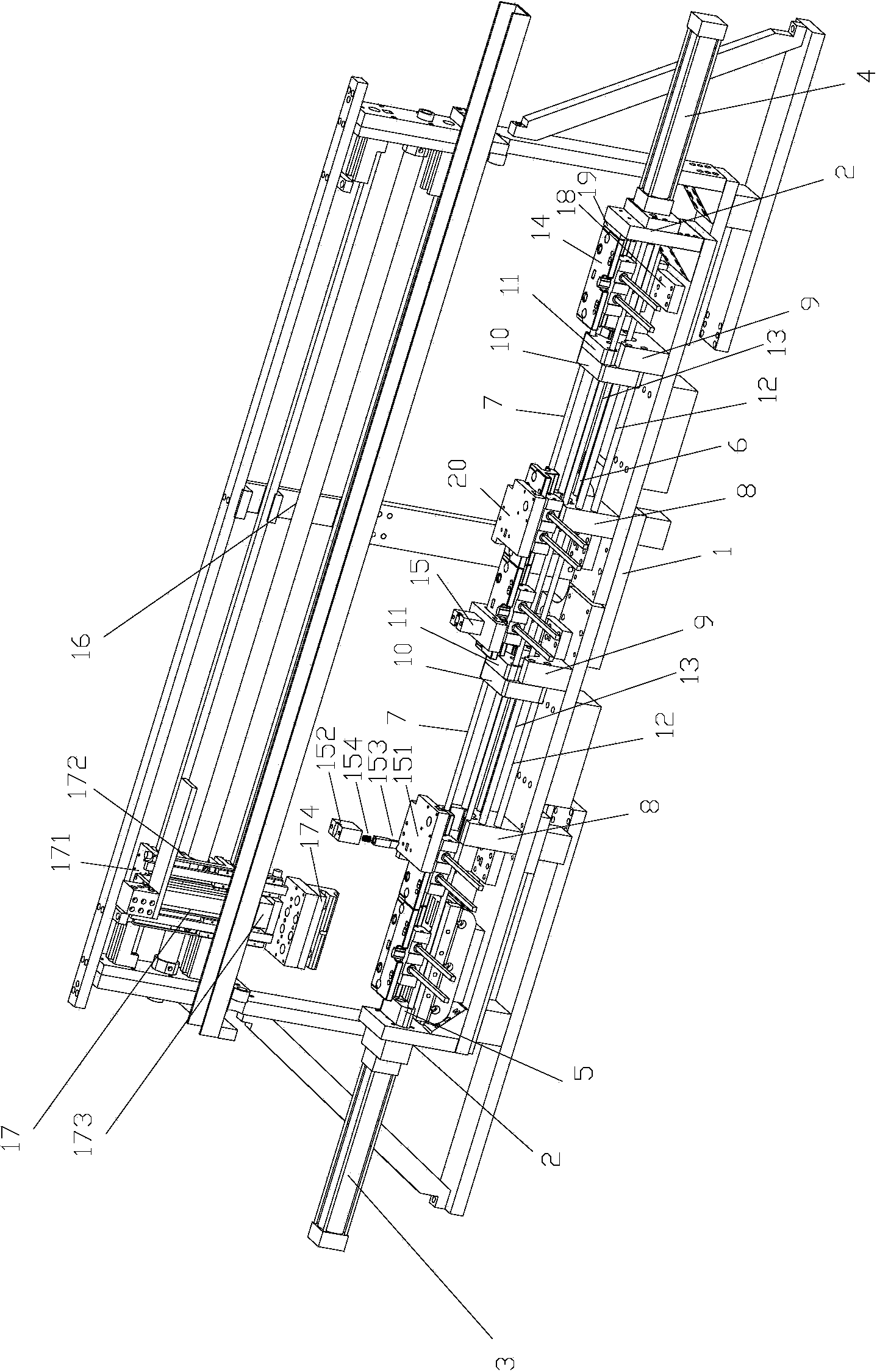

[0023] Example 1 as figure 1 As shown, a multi-station automatic transmission mechanism for workpieces includes a base 1, side plates 2 are arranged at both ends of the base 1, a left drive cylinder 3 and a right drive cylinder 4 are respectively arranged on the outside of the two side plates 2, and the left drive cylinder 3 pistons The end of the rod is provided with a left driving block 5, and the stroke of the left driving oil cylinder 3 is not less than the length of the workpiece in the conveying direction. The piston rod end of the right drive oil cylinder 4 is connected with a drive rod 6 . Two slide bars 7 are arranged between the two side plates, and the left drive block 5 is sleeved on the slide bars 7 . The slide bar 7 is provided with an initial station, several work stations arranged at intervals and an end station from left to right. The setting position of each processing machine needs to match with each work station.

[0024] Each work station on the base 1 ...

Embodiment 2

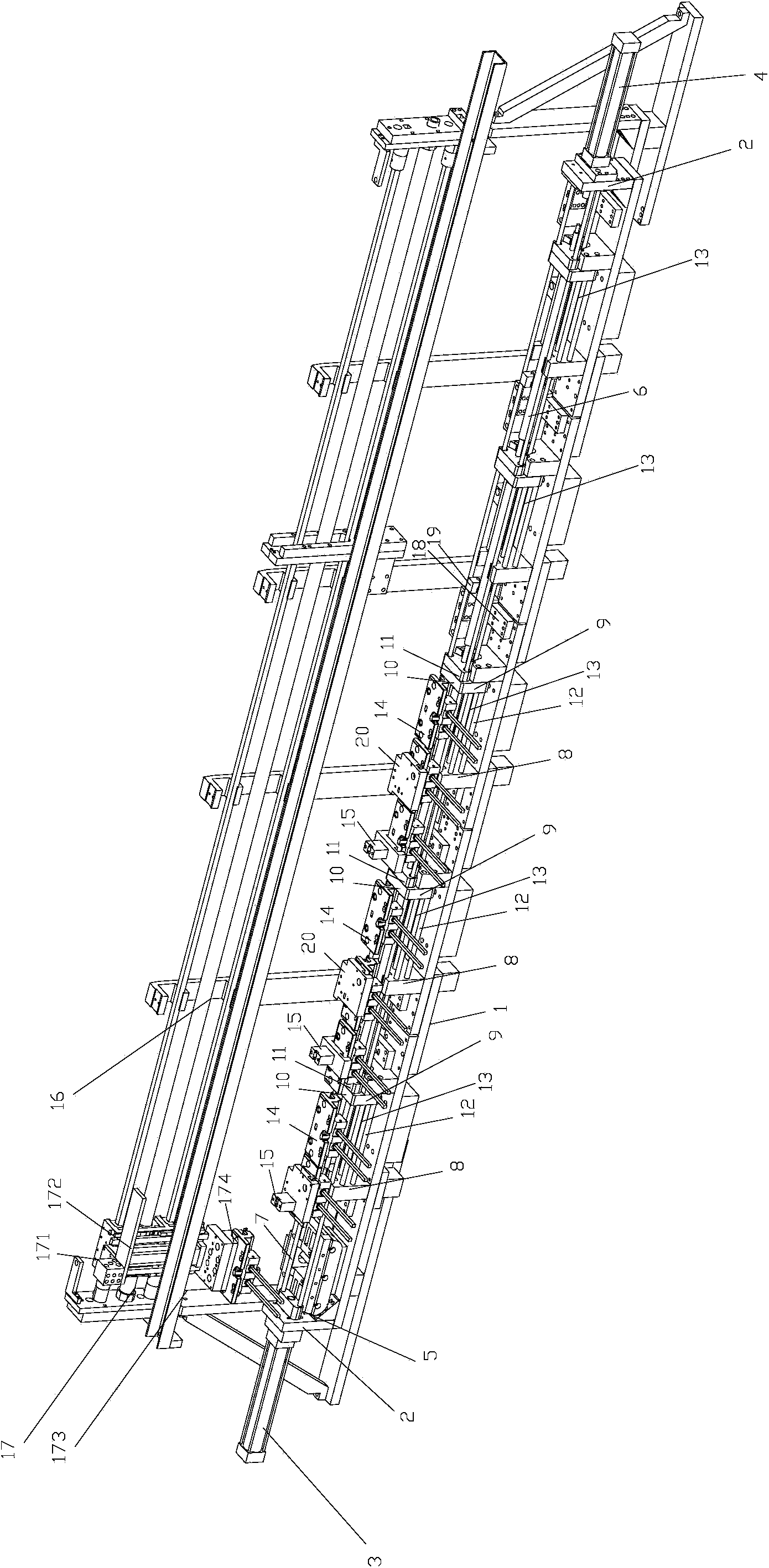

[0029] Example 2 as figure 2Shown is a transmission mechanism with five working stations for three-station transmission. Compared with Embodiment 1, the difference is that two more working stations are provided, and the tail stopper 19 is set at the third The right side of the working station, and the stroke of the transmission dolly 17 is adjusted to be applicable to the state of three stations.

[0030] The transmission mechanism needs to be used in conjunction with the workpiece feeding mechanism. If a push-type feeding mechanism is used, the single working cycle is: the right drive cylinder 4 is retracted, so that the left slider 10 and the right slider close to the left positioning block 8 on each working station 11 Push the workpiece clamping seat 14 on the station to move to the right until the left slider 10 touches the right positioning block 9. At this time, each right slider 11 pushes each adjacent workpiece clamping seat 14 to make the closest Each subsequent wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com